In case he decides not to, which would be very reasonable since it's still a lot of work to make a body after you have the molds, here is an alternate source for an accurate copy of a real Lola Mk.2 Spyder, which will fit on a real chassis or a dimensionally accurate copy thereof:

Toluca Lake Classic Motorsports

I would expect you're looking at ~$10K+. The materials and labor for a body are approximately $5500, which I know from the McLaren M1A, B and C bodies we do. Which is a lot of money on the one hand, and nothing if you figure the time it takes to do this, especially including making the molds.

To make these molds, if you had a body to splash, would likely be in the range of $20K or so, but per hour it's probably not minimum wage unless you have a lot of experience and all the stuff to do it.

No, we don't do Lolas. I'd buy a body from these guys if I wanted/needed one. Lolas are prettier, except maybe for the M1A. M1B and M1C aren't ugly, but they're not a T70.

Actually, even if I wanted to be able to make my own,(not a bad idea if you're going to take the car on the track and therefore are likely to need more pieces) I'd buy one of theirs and just copy it.

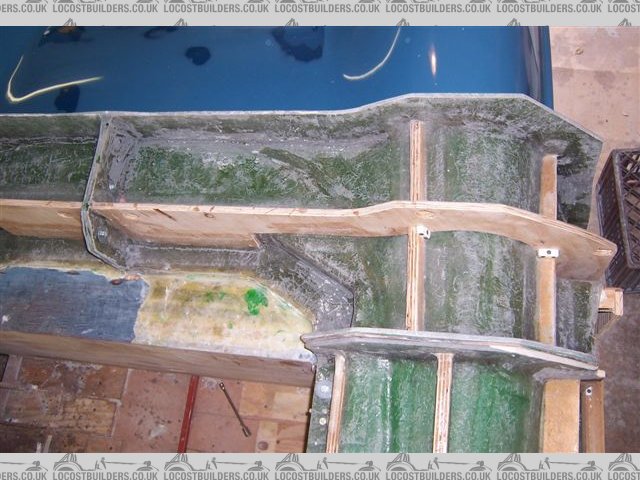

Doing this from scratch (as oppose to splashing another body) is an absolutely amazing accomplishment, especially if it would fit a T70 chassis.

I sincerely hope that an even more careful and thorough job is done on the chassis, since that's really the car, this is just beautiful cosmetics. It's standard practice to drive the completed chassis without the body to shake it down and set up the suspension, then add the body after it all works properly.

If you don't just copy some known good geometry, and the T70 was/is known as an extremely nice driving car with no vices, please be very, very careful, especially with the geometry. It's most important that it not do anything funny, especially at the extremes of the trafel, and most especially at full compression when it would be heavily loaded. Many geometrys are fine in the middle of the travel but diverge drastically at the ends, and that will get you killed.

This is not golf, and is a classic example of :

"We do dangerous things very, very carefully" - William Slaughter

Otherwise what you have is a truly gorgeous piece of scupture, but not a car to be used in anger. That's my heatfelt opinion, at least.

Please be careful.

David Merritt