As some of you know the car is currently in Connecticut with Allan

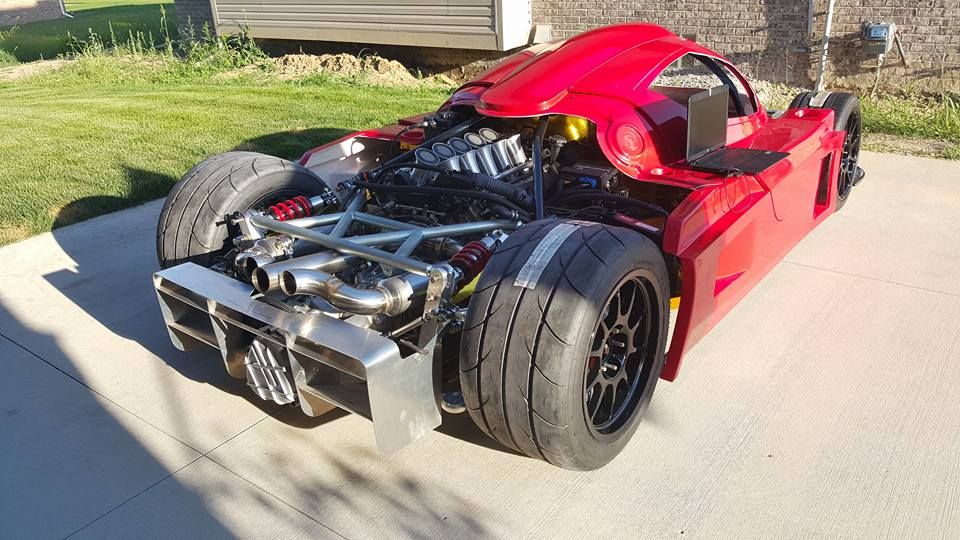

getting some major work done. Allan just finished painting the body

and is currently working on making a custom center console for the

gated R8 shifter. I got really lucky one night when I was browsing for

a R8 shifter assembly and came across one for sale on ECStuning.com.

Normally for sale for $1300-$1400, It was listed at $109 with free

shipping so I purchased it instantly. Luckily for me they shipped it

with no problems.

I have to say Allan is doing one hell of a job. For those considering

sending your SL-C to him have no worries its in great hands. He is a

very talented individual and very trustworthy. If I didn't have Allan

as an option my car would probably still be in the body alignment

stages lol.

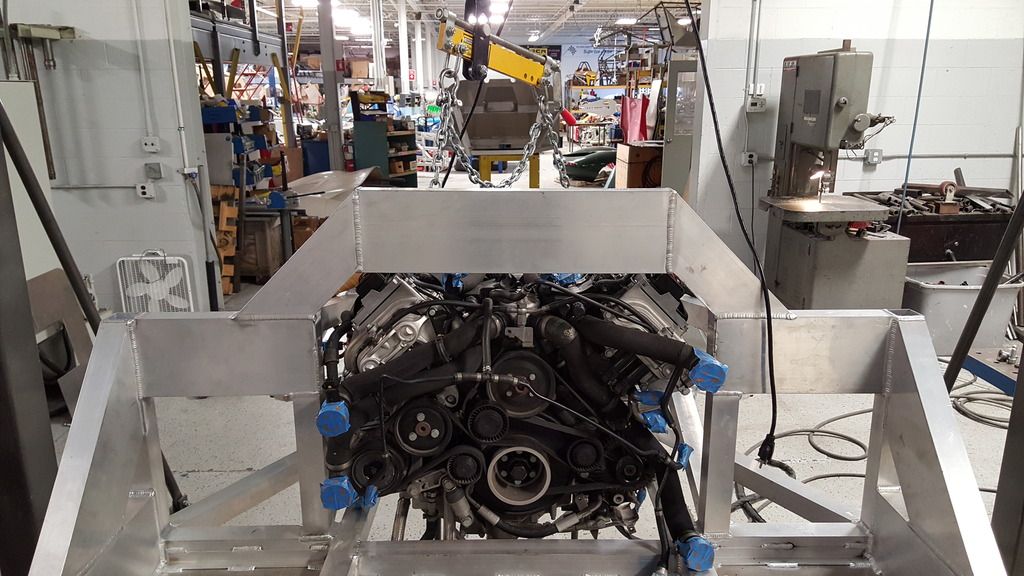

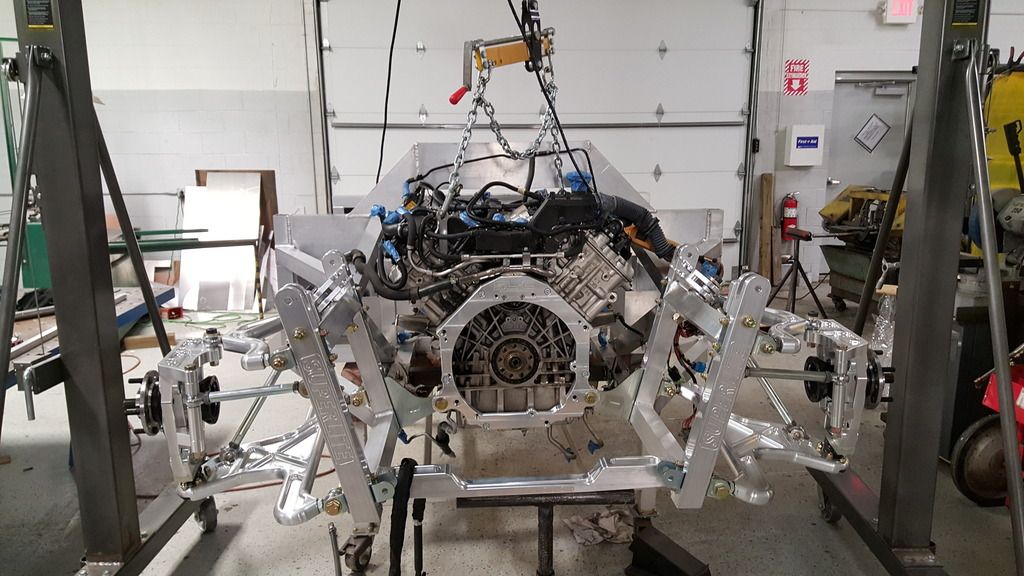

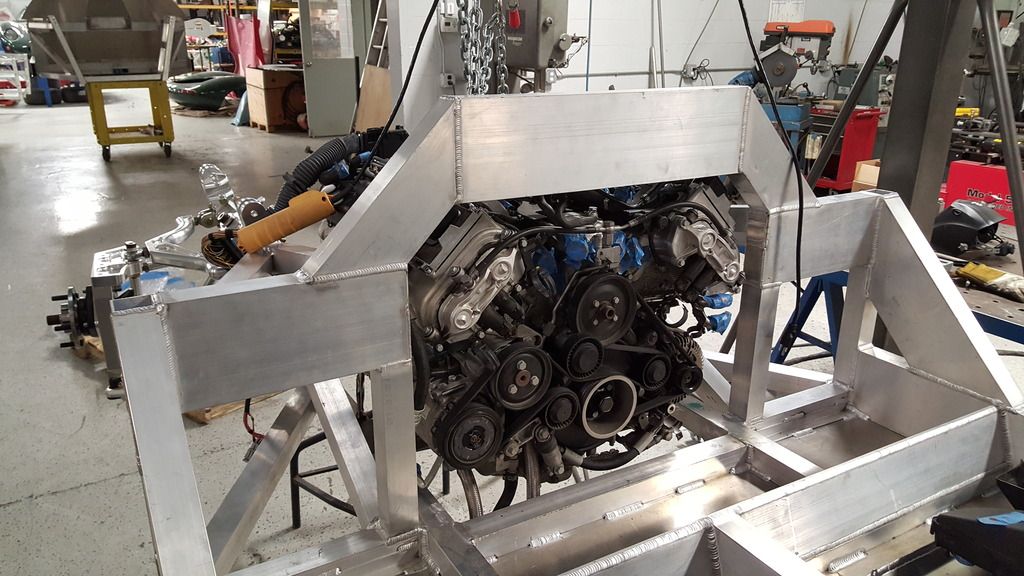

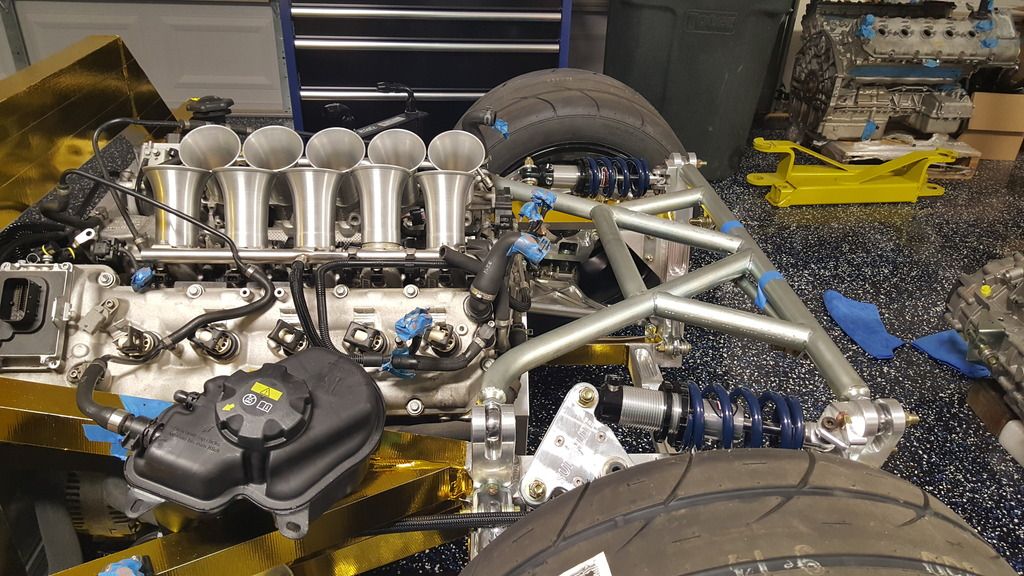

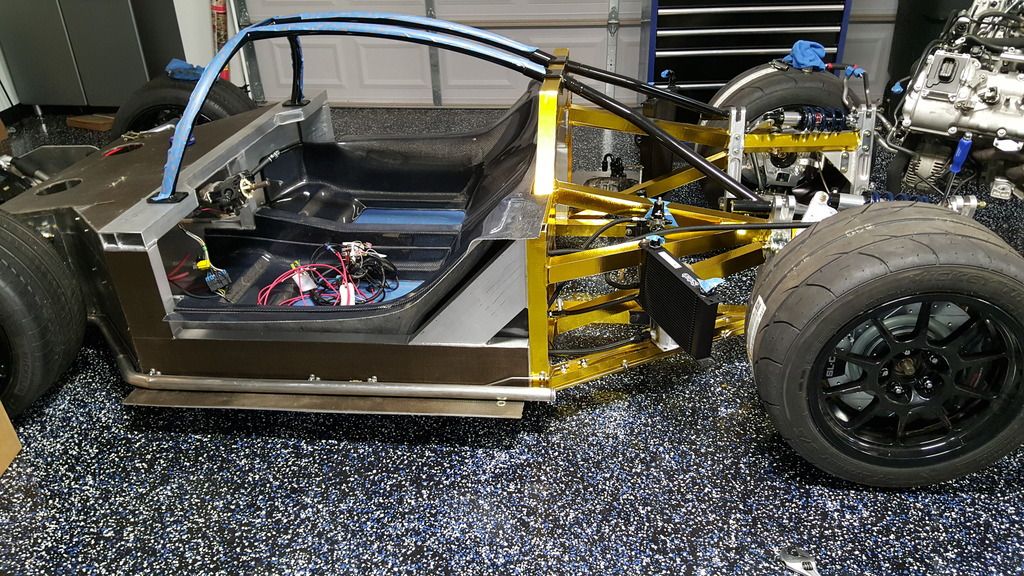

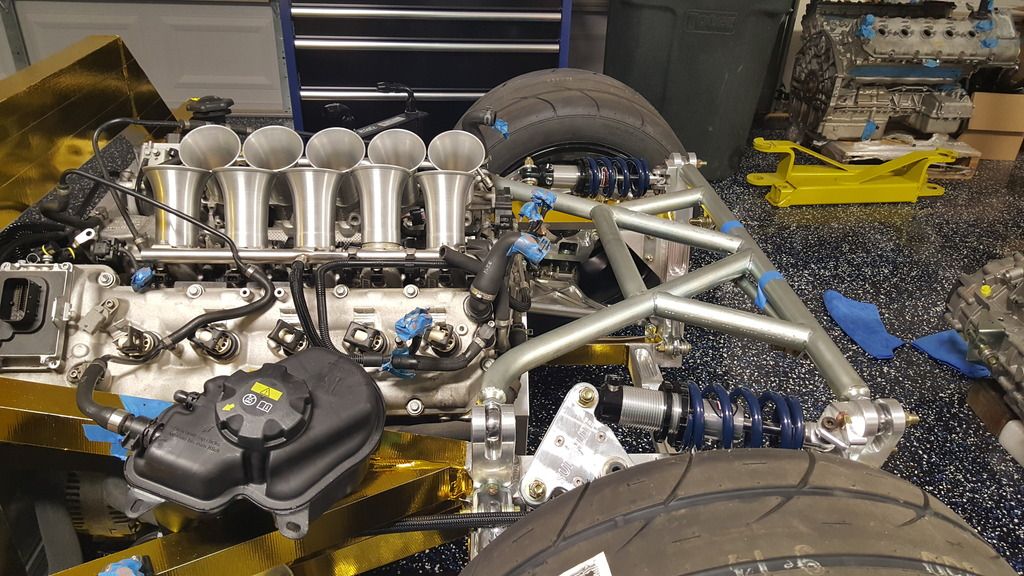

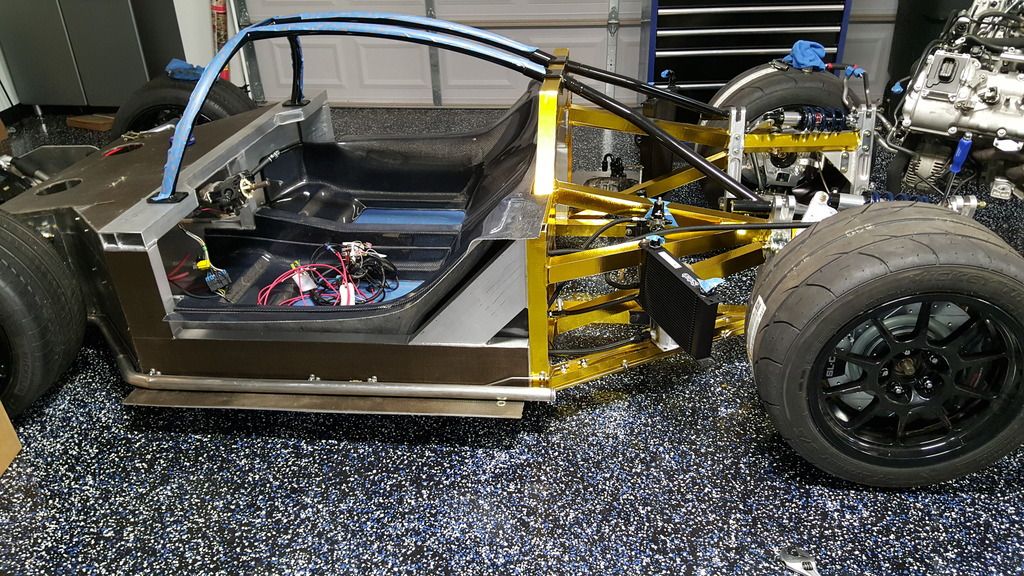

So here are a few more pictures of modifications I had performed to

the S85 engine to work in conjunction with the SLC.

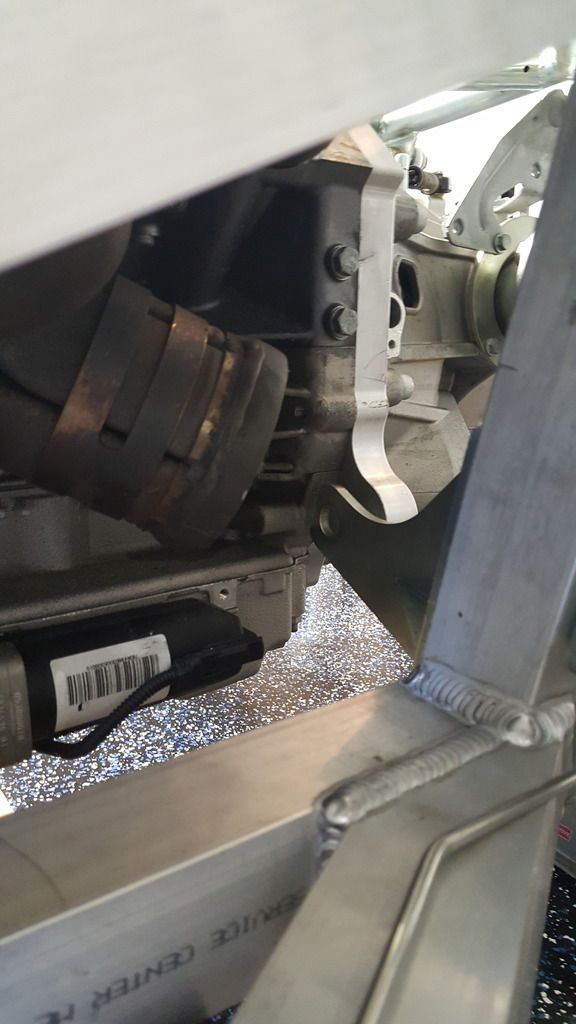

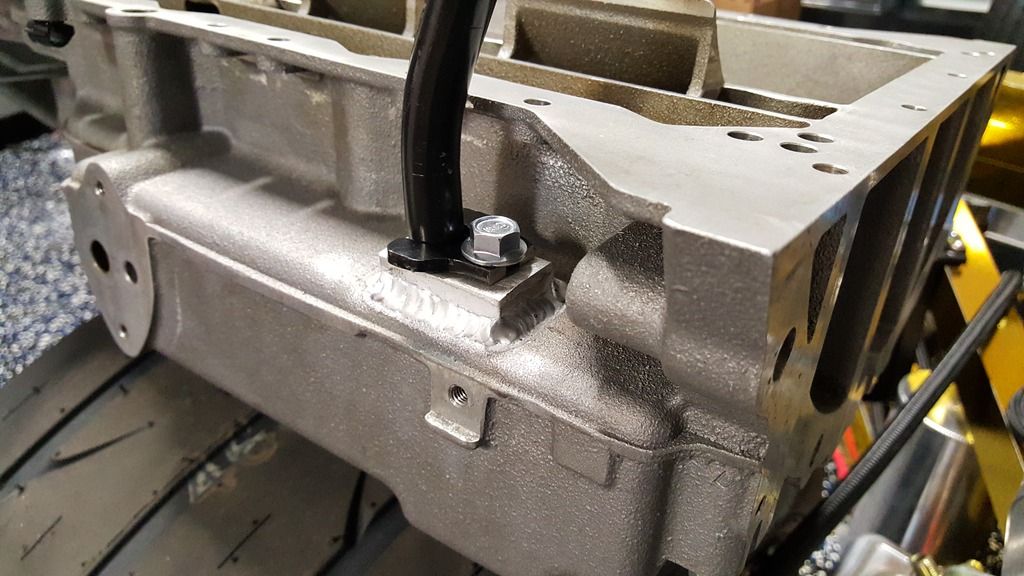

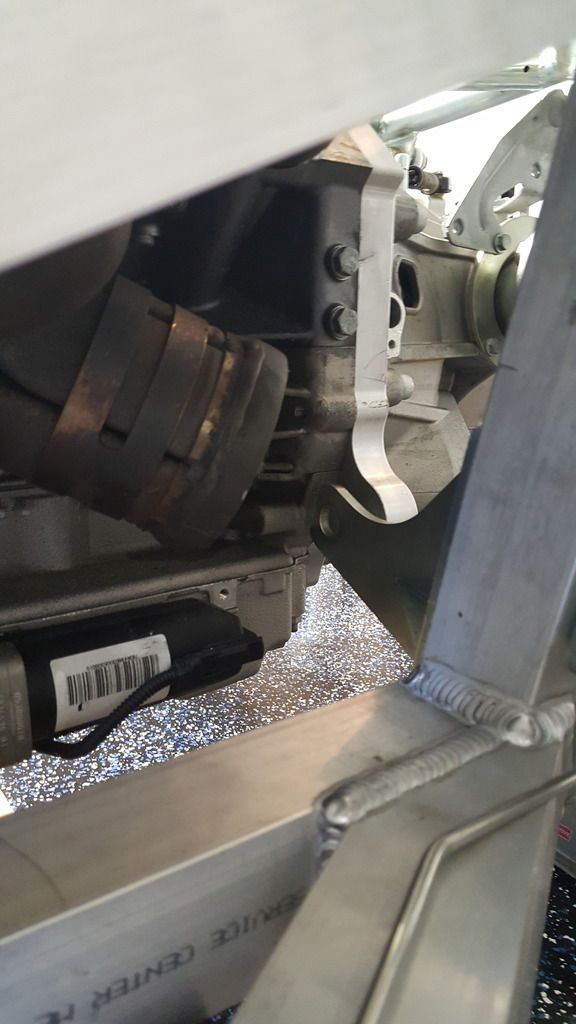

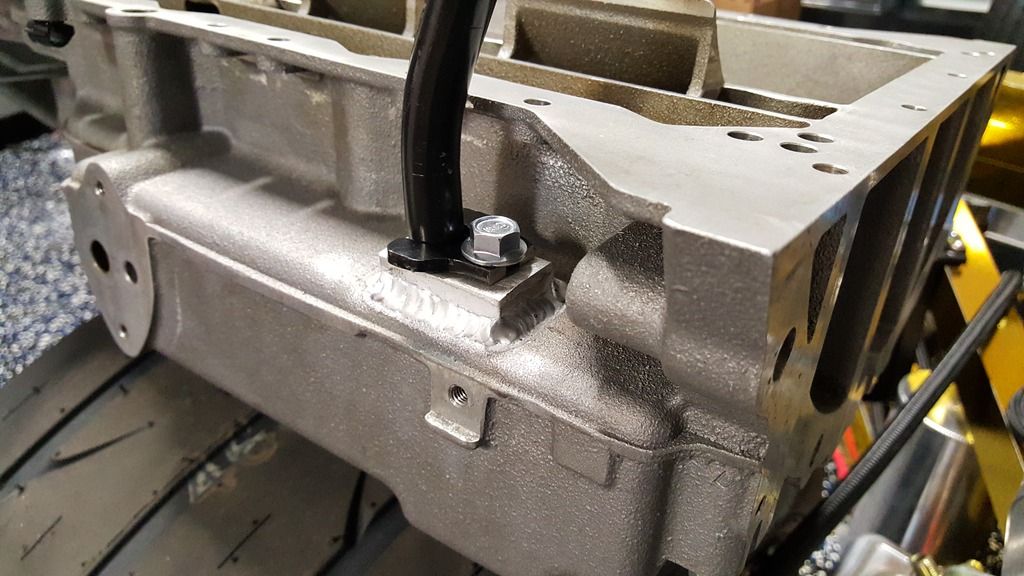

Here's a*picture of the header/trans mount clearance problem I had. I

ended up modifying the existing mount and mounting it to the back side

of the trans bracket. This gave me more room and was able to use a 4"

90 degree exhaust pipe over the bracket.

I decided to move the engine back 1.25" to gain additional clearance

near the bulkhead.

Fuel tank fuel inlet had to be modified to clear part of the chassis

which was modified.

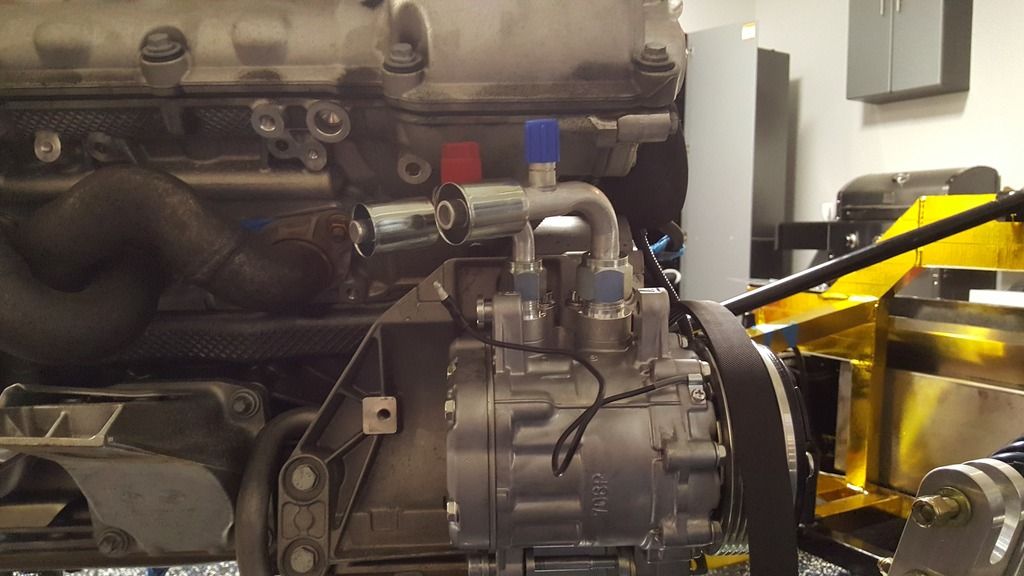

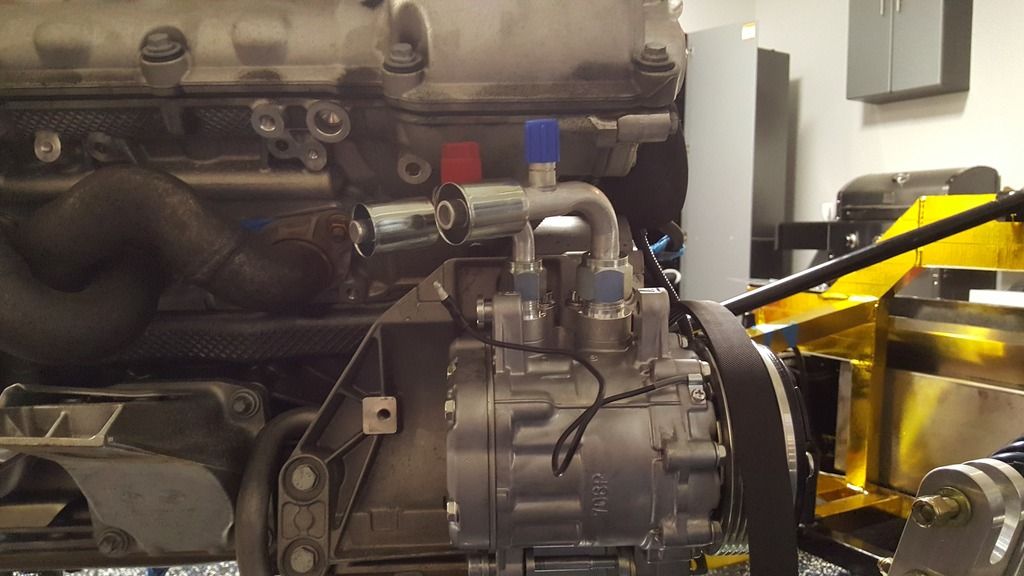

Mounted the compressor that came with the Vintage air kit. I had to

modify the existing brackets and also make a few of my own which are not pictured here.

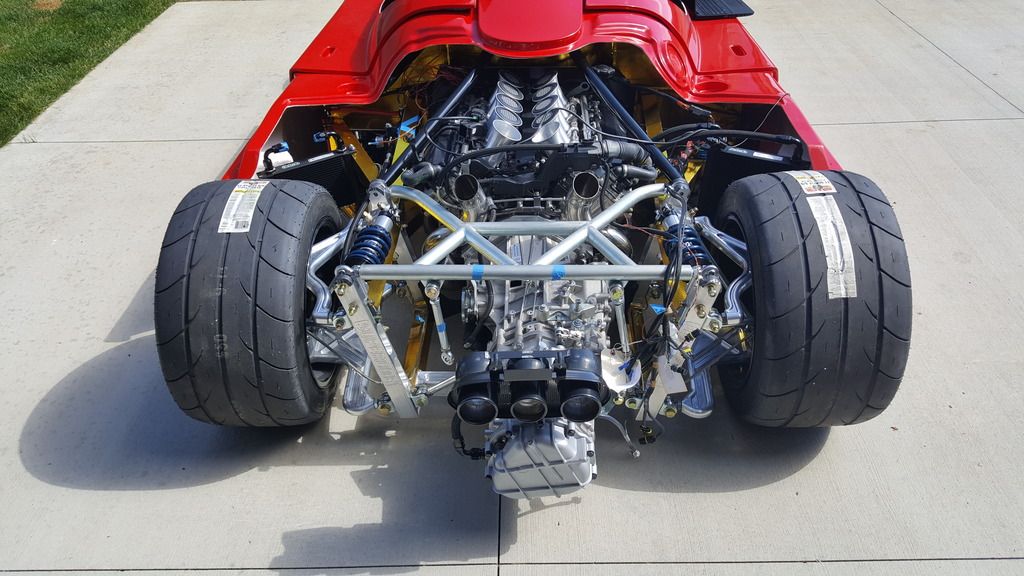

The s85 normally has a split cooling system . This is where I ran into

a few problems. The engine has 2 coolant outlets and 2 inlets. To make

life easier I ended up welding 1 thermostat port closed and merged the

2 outlets from the heads into a y-pipe leading to the front of the

engine. Once I had the engine running I tested the cooling system at a

stand still for over 1.5 hours. Thankfully I didn't have any problems

with overheating. We'll see how well the cooling system works at WOT

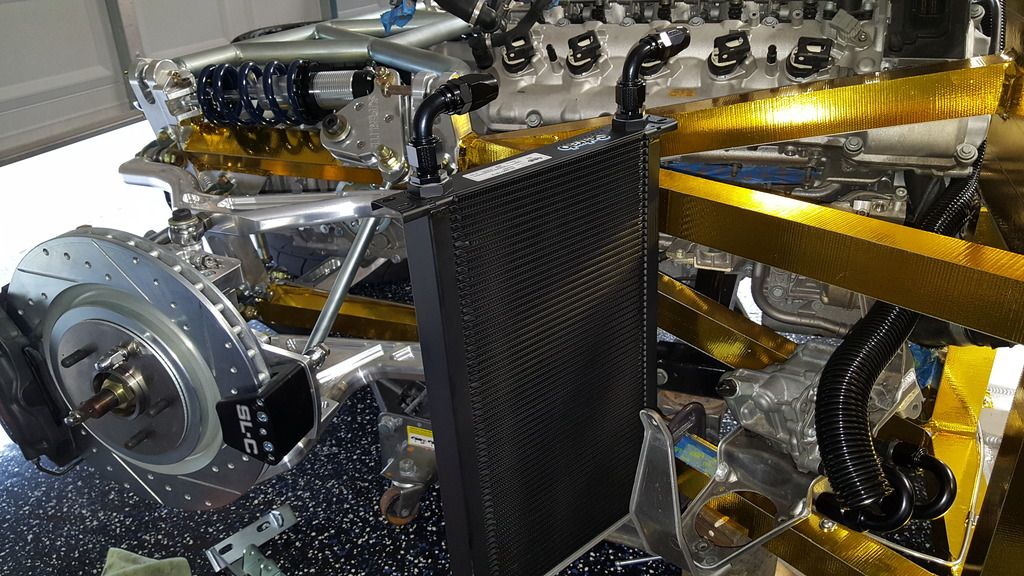

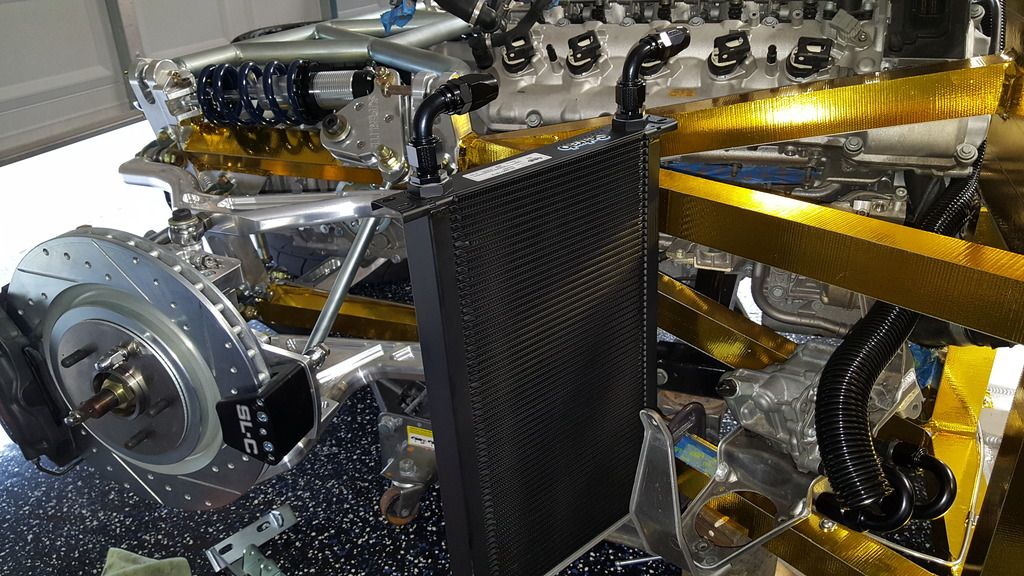

on the track. Also decided to go with Setrab oil/trans cooler.

I ended up tacking up all the coolant tubes together and had a local

welder weld/back purge all the pipes. After I tested it for leaks I

painted it with High temp. resistance flat black paint.

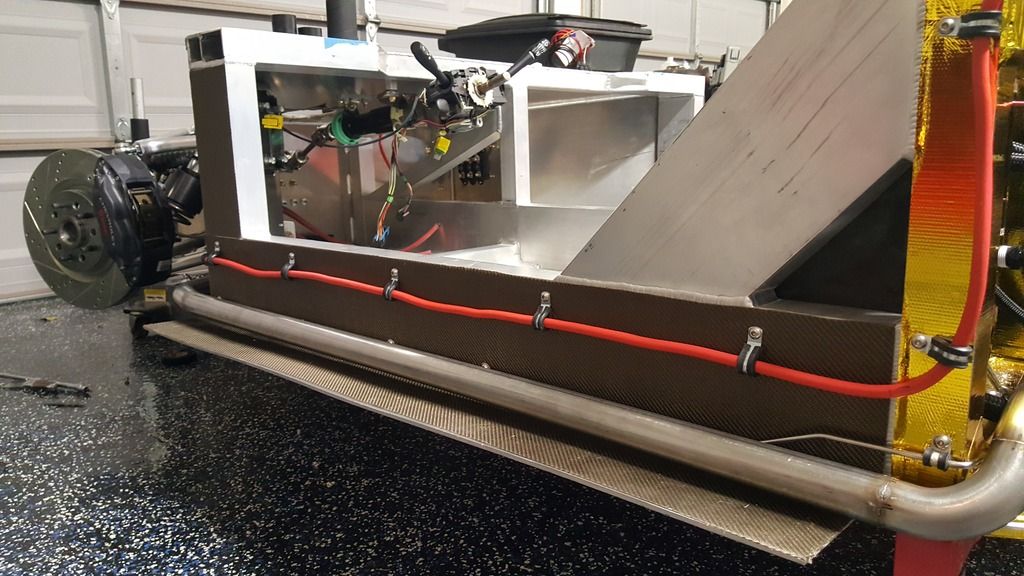

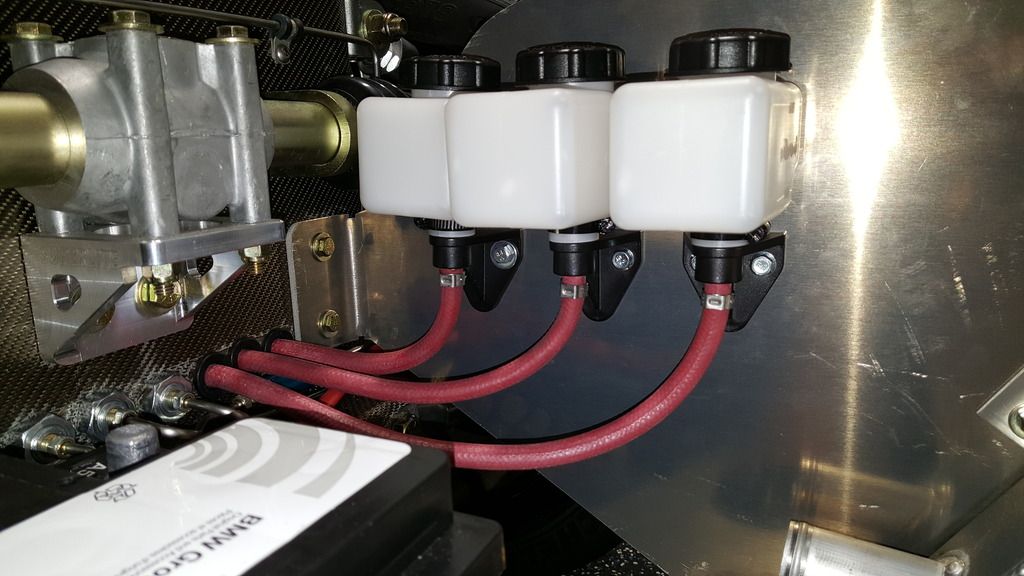

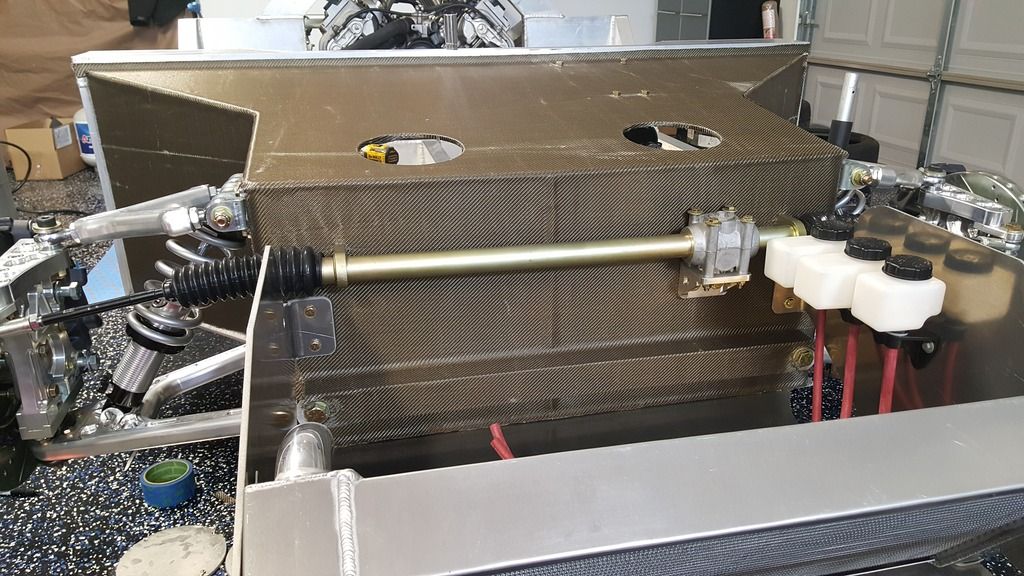

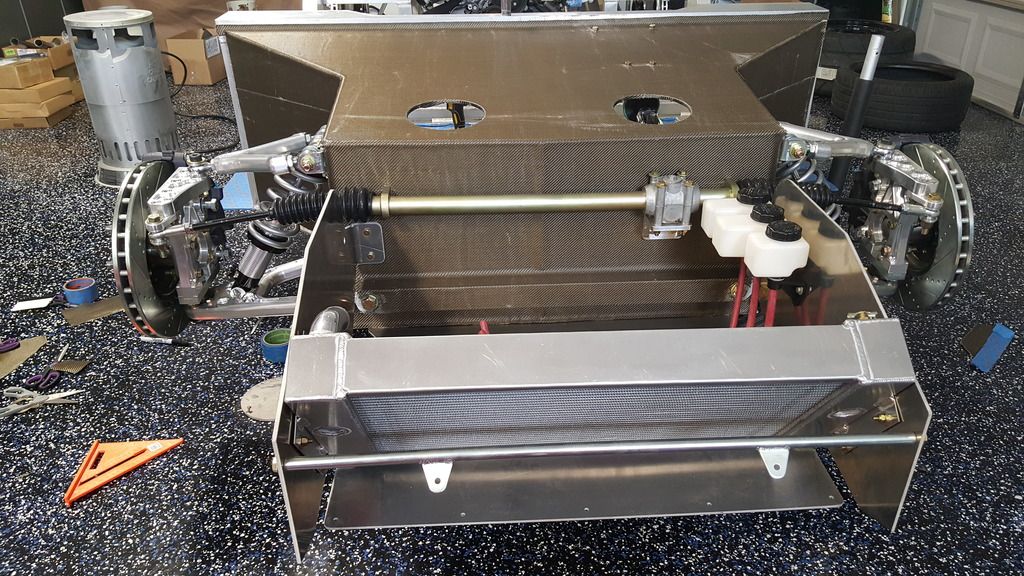

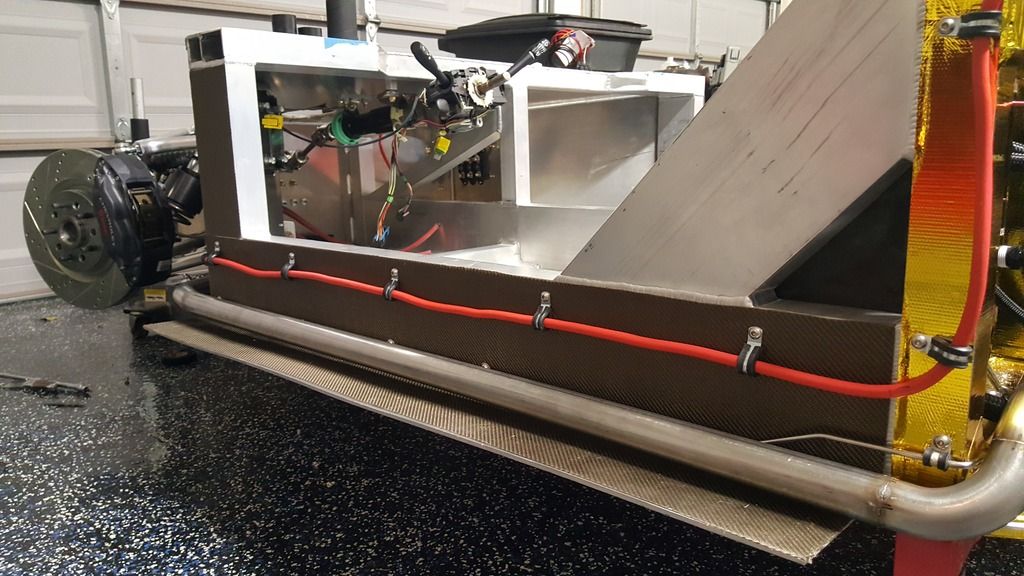

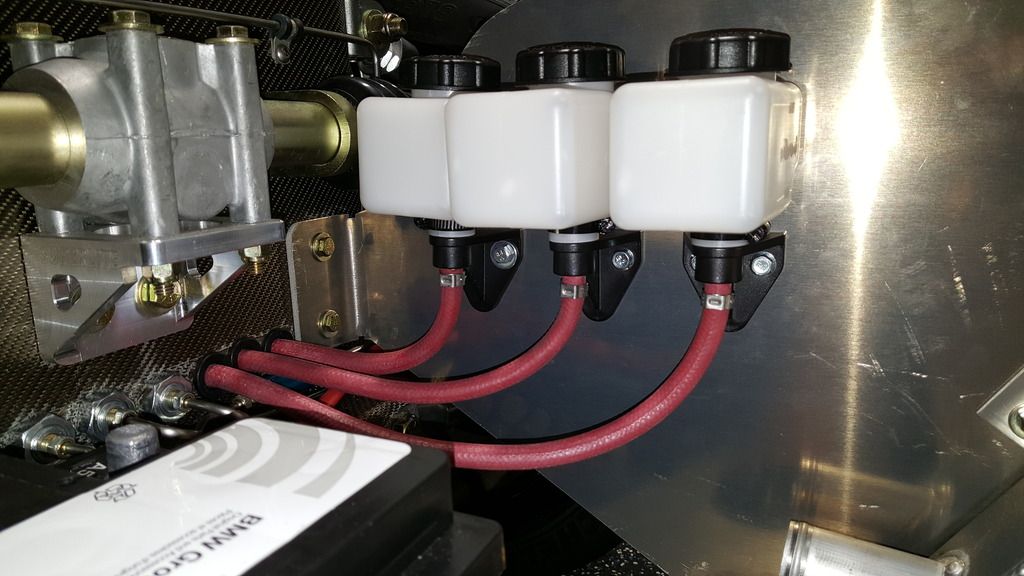

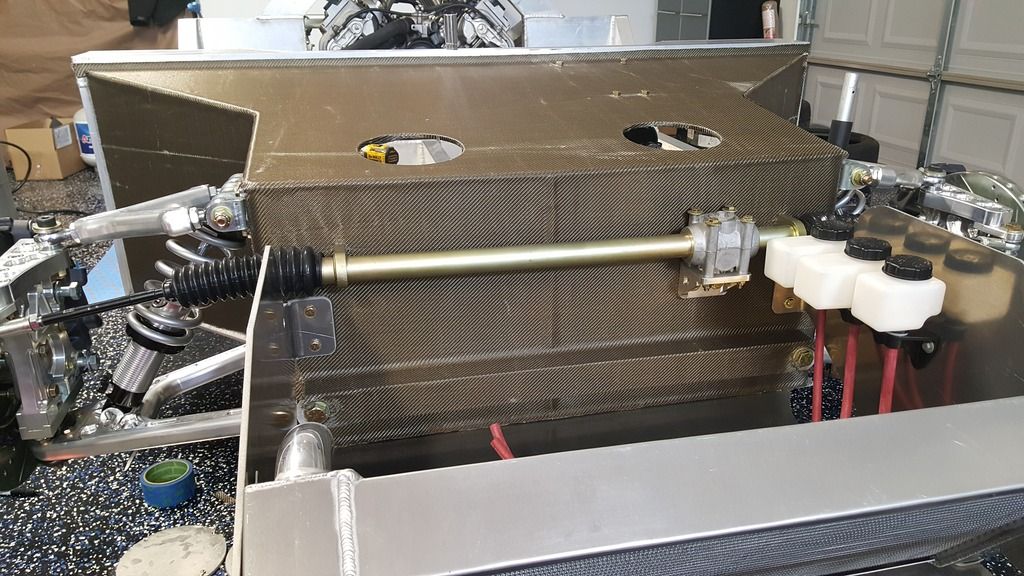

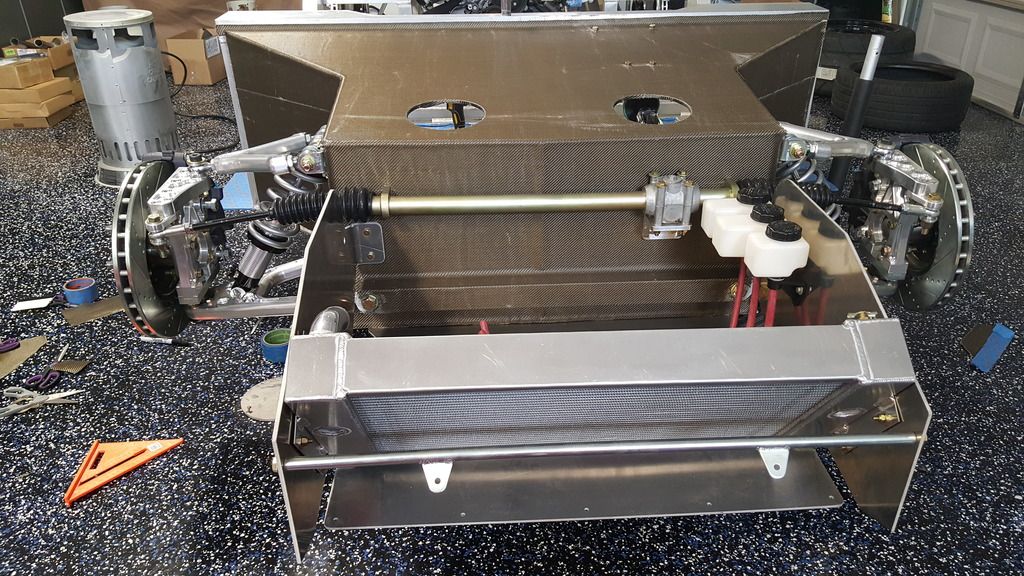

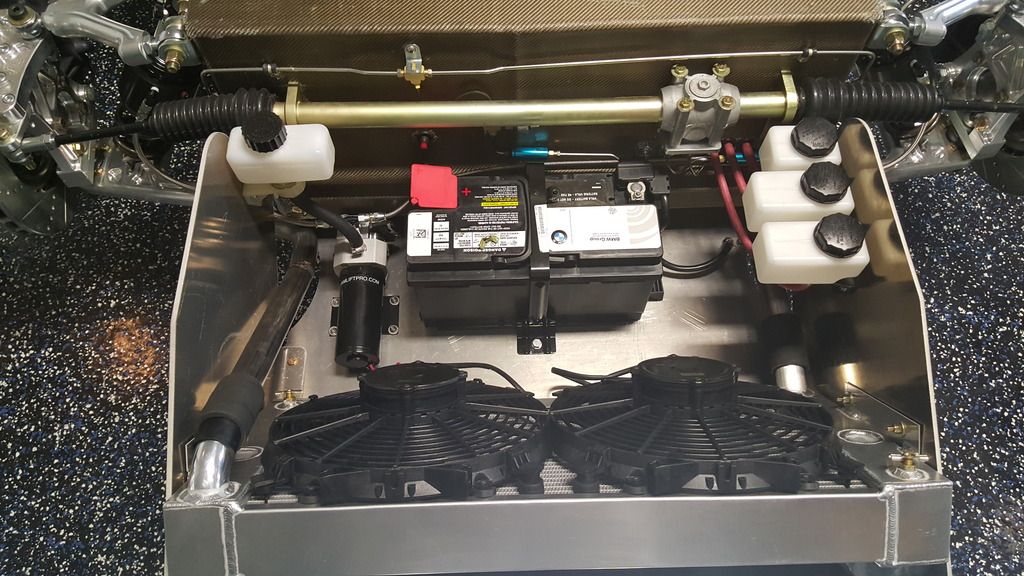

Brake lines installed

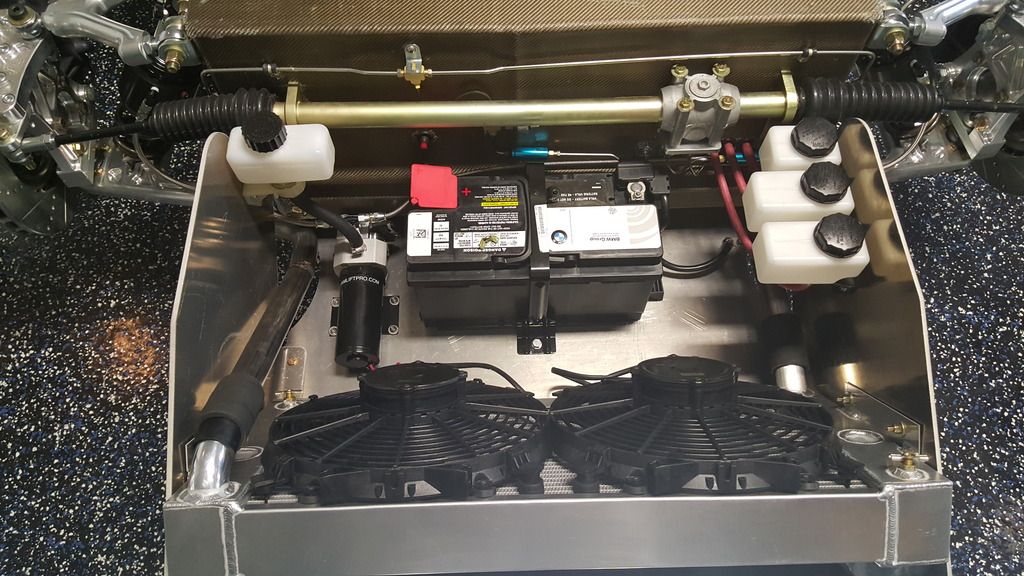

Brake/clutch reservoirs mounted

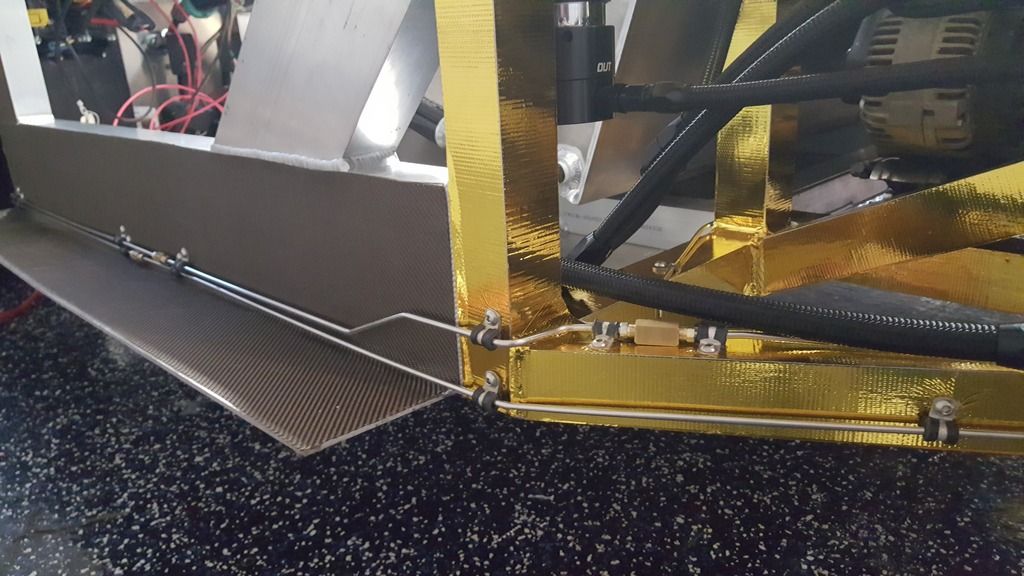

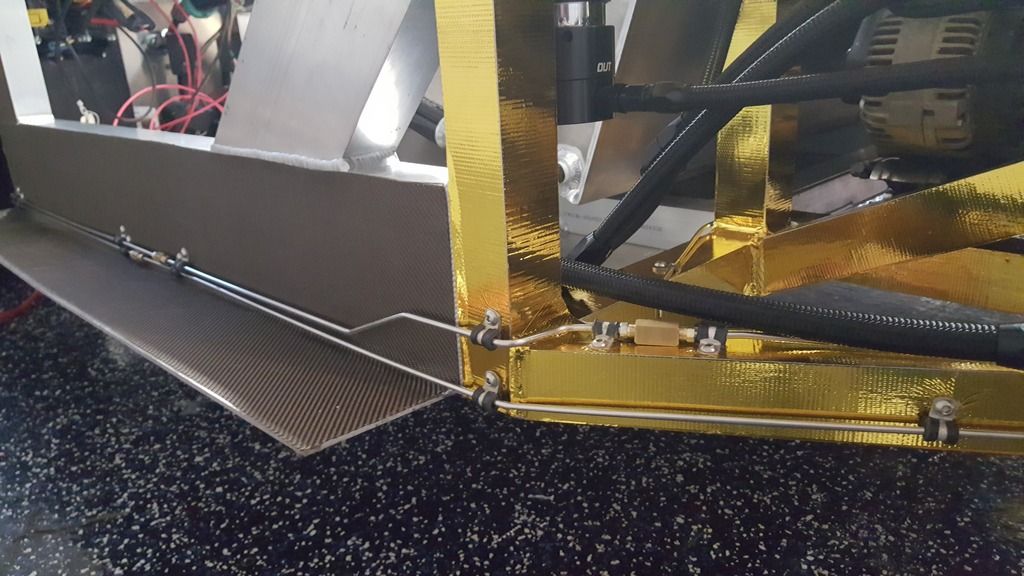

I did install Lava mat thermal barrier to prevent as much heat transfer to the passenger compartment. If ordering the same material make sure to get the thicker stuff. I believe its .025" thick.

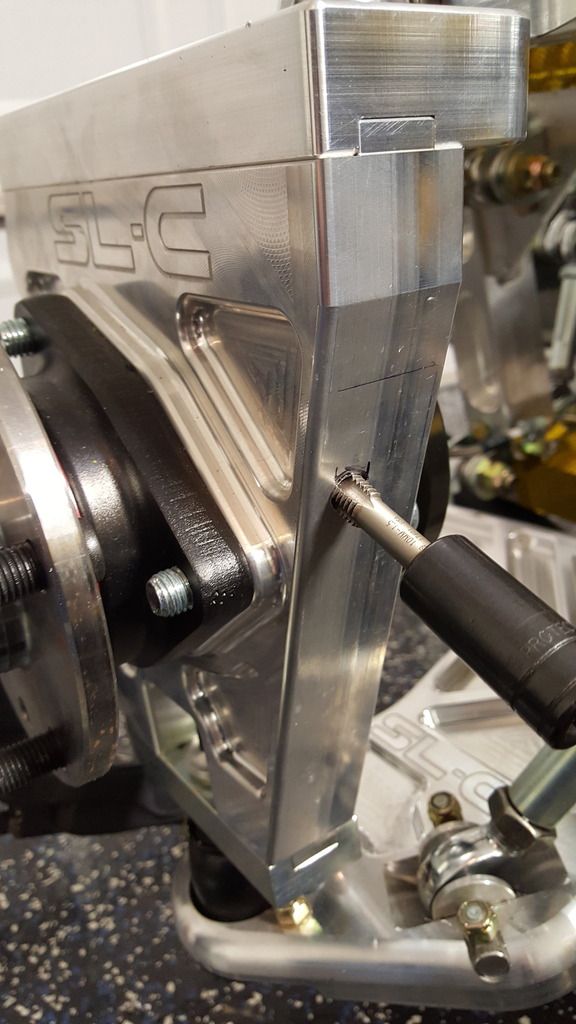

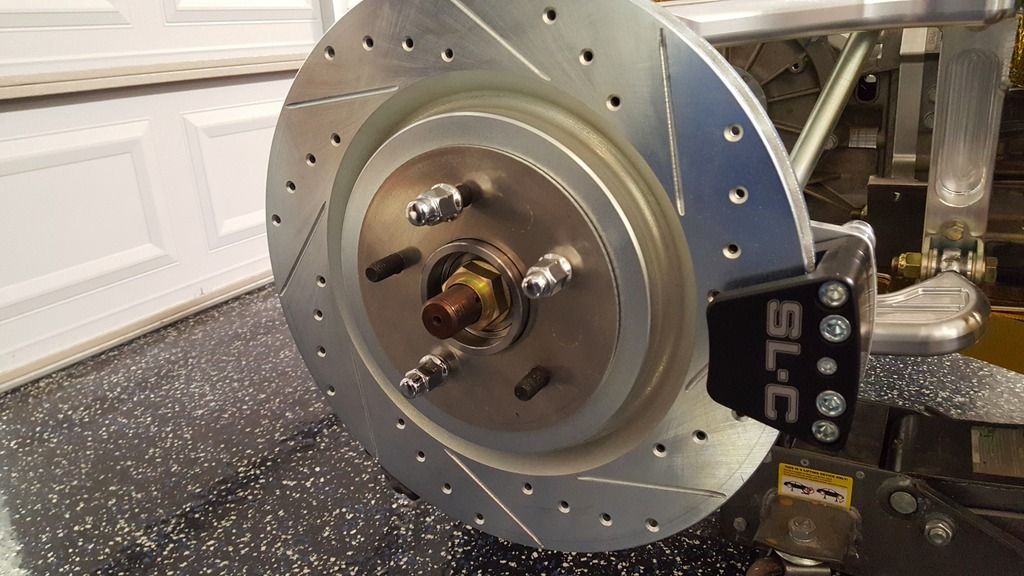

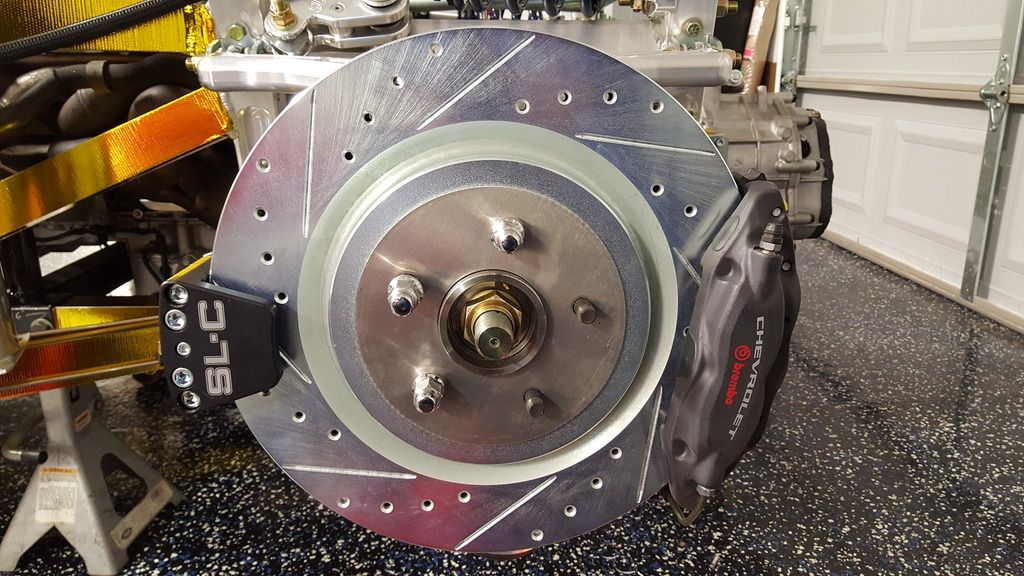

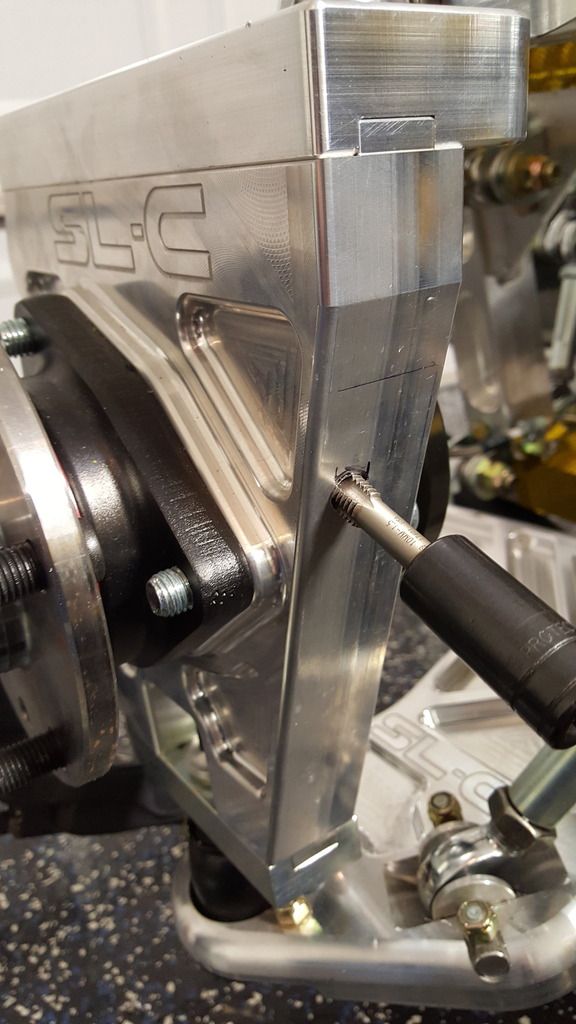

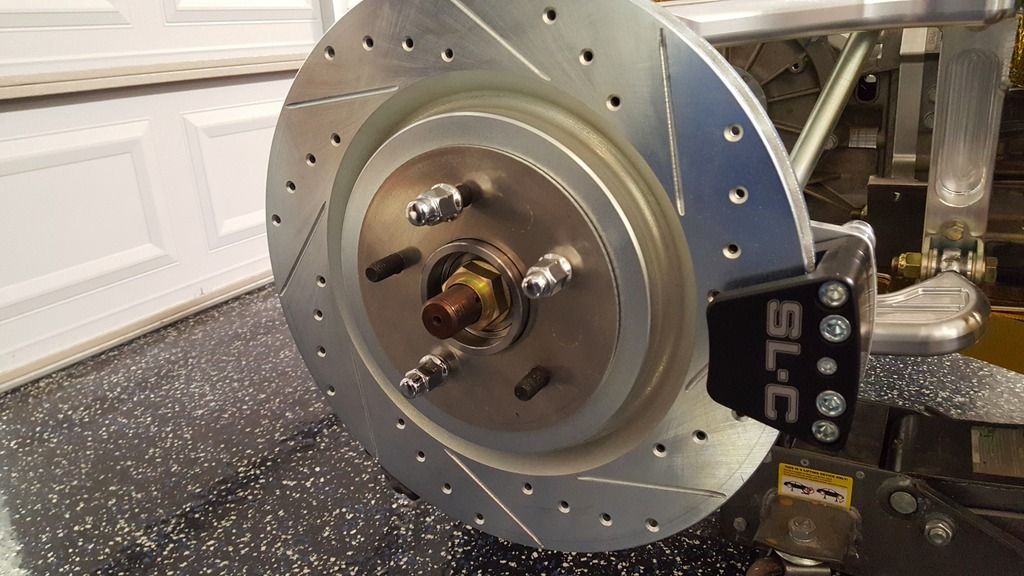

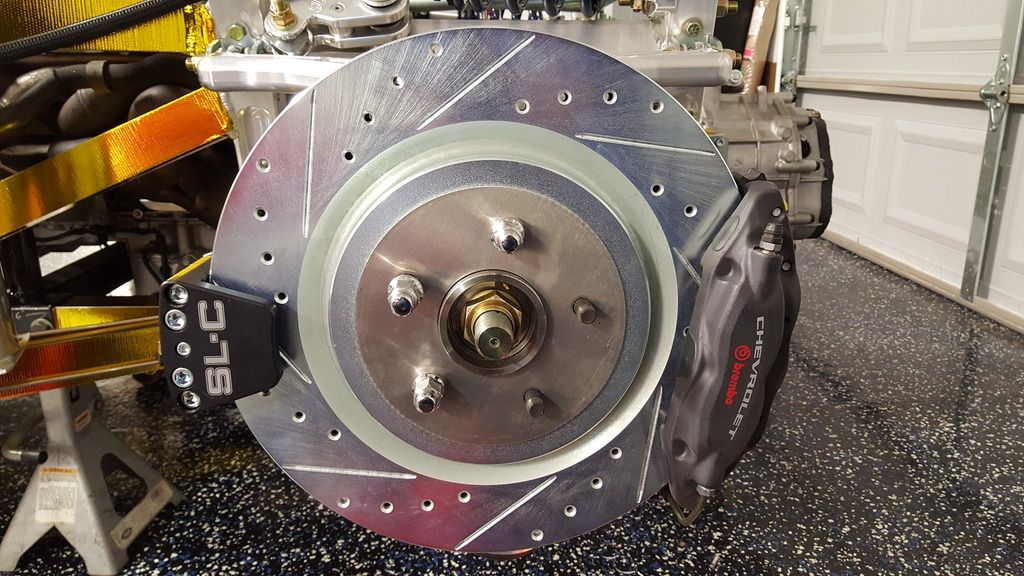

E-brake calipers brackets tapped/installed. I did make custom brackets to space out the calipers just enough so that when I drilled the holes through the uprights I didn't come through the open area.

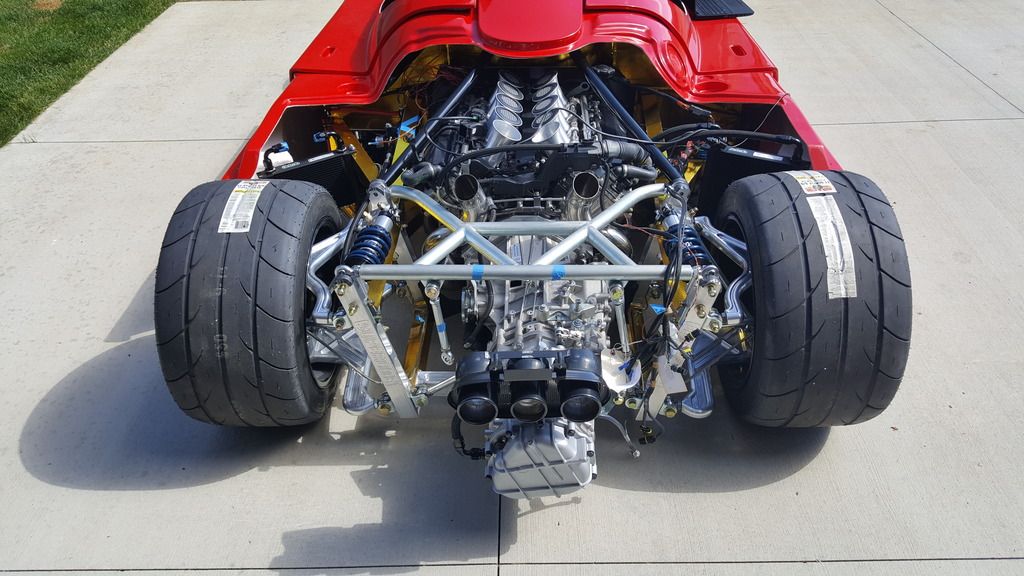

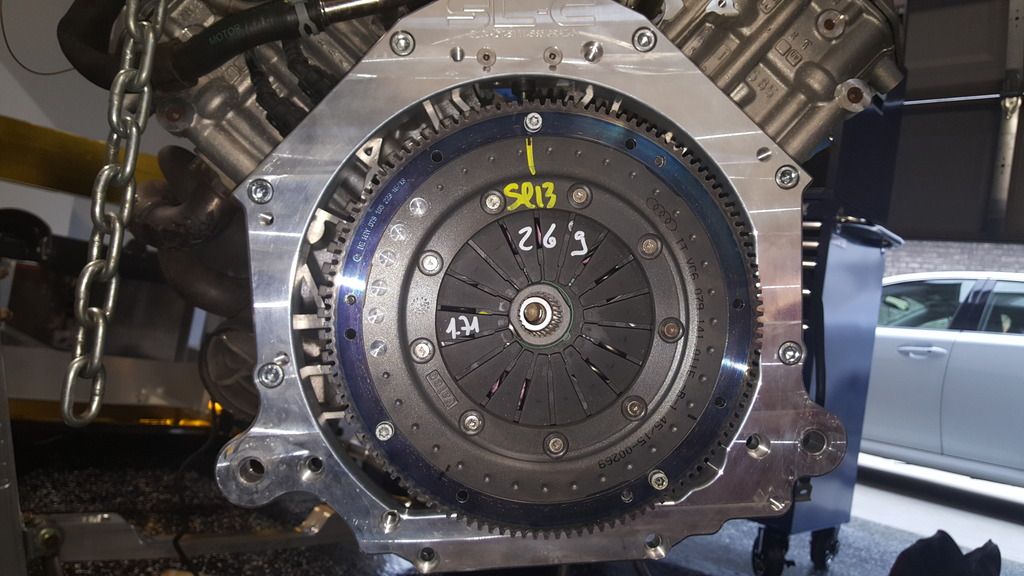

The S85 engine oiling system is a quasi-dry sump therefore multiple oil pumps are used. This engine has a total of 5 oil pumps. This includes 1 main 5 bar pump, a suction pump that transfers oil from the front section of the sump to the rear, 2 lateral oil pumps that are activated in excess of .8g's and 1 vanos high pressure oil pump that runs the vanos actuators.

Here's the oil filter housing mounted to the chassis. Just kind of mocked it up to see whats the best place to mount it. The coolant line was just for testing to if a tube would actually fit in between engine/chassis.

Oil cooler lines modified for -10 an.

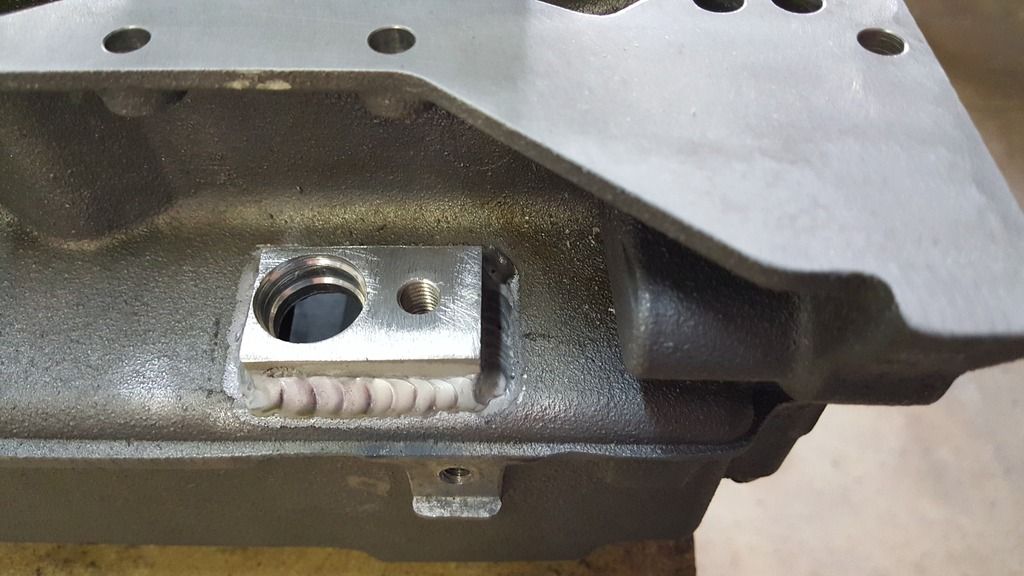

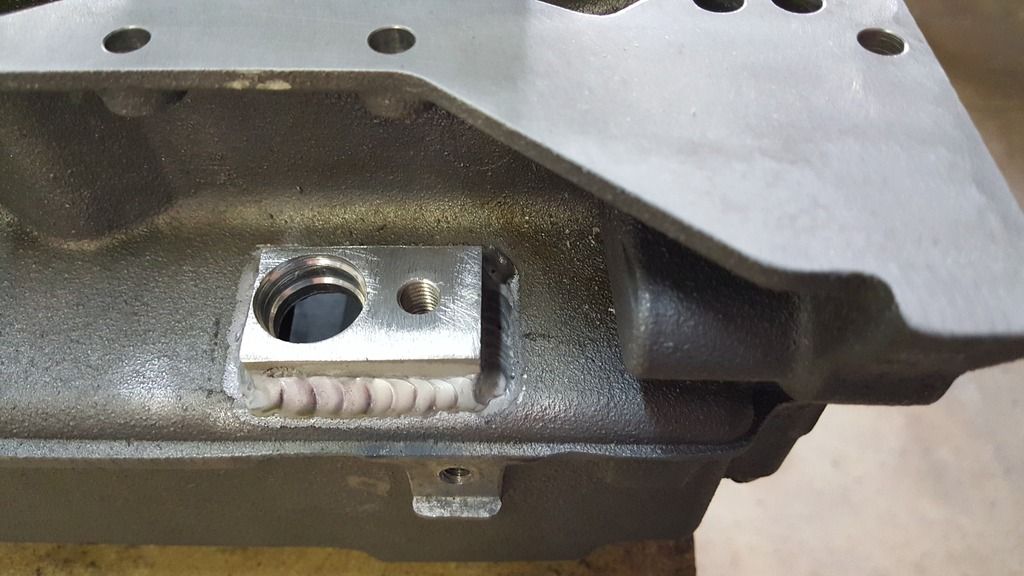

Unfortunately this engine does not have dipstick from the factory. From the factory they used a Electronic dipstick mounted in the sump. I improvised and modified one from a M62 motor. I removed the sump, I drilled and added my own custom bung to the top of the sump. Once welded to the sump I then used water to measure the full mark on the dipstick. It was a lengthy process but definitely had to be done.

I then added a front drain plug for the front of the sump.

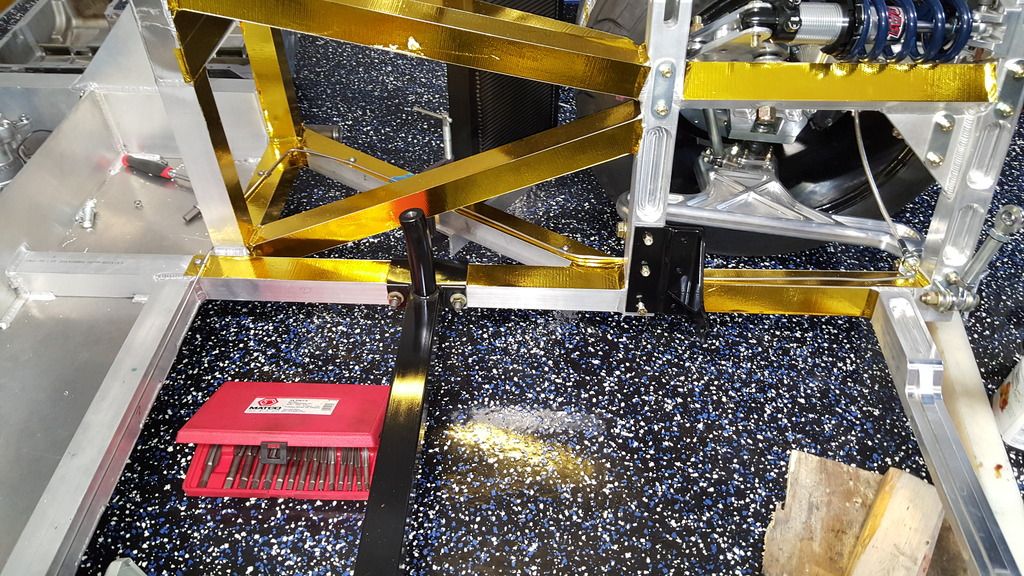

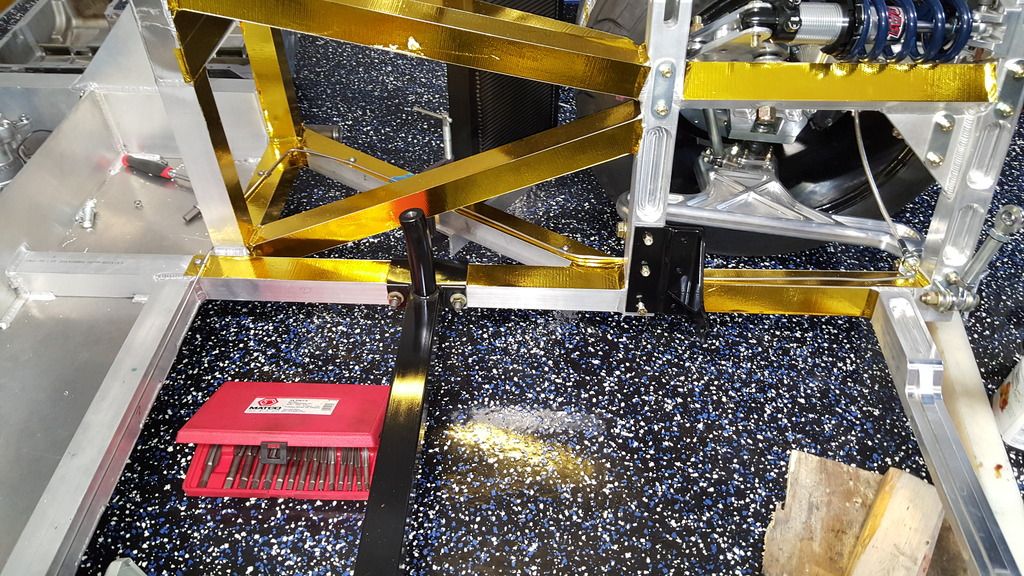

Here's are picture of the upgraded Maradyne fans and front lift kit installed.

Having the engine out multiple times really sucks, but in my case I had no choice.

Engine had to come back out to modify a few brackets. Having a hoist in my garage definitely made it easier to do.

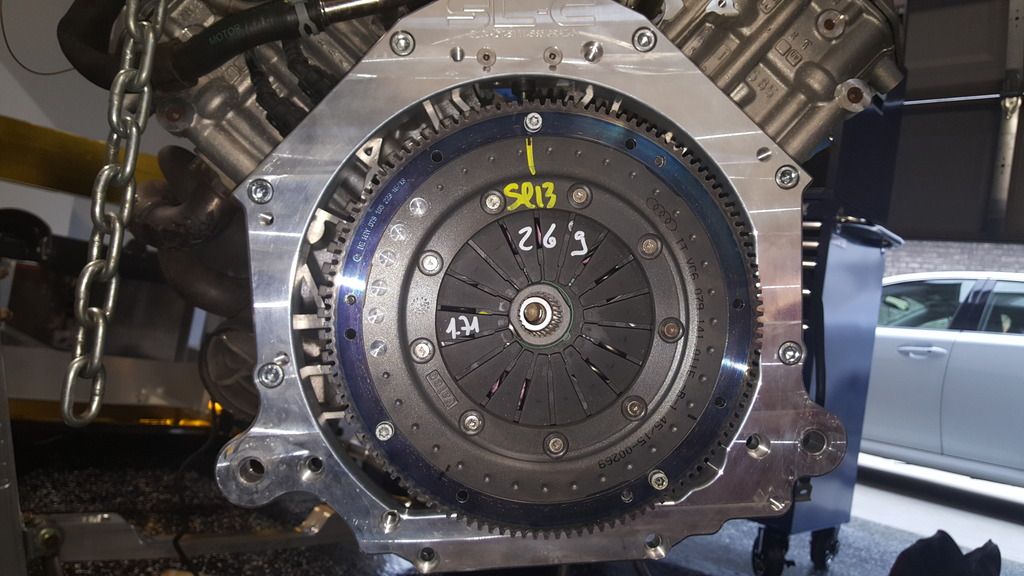

Installed the custom flywheel pickup wheel and sensor gapped correctly.

Trans installed, I decided to remove the black material from the back of the trans and paint it silver.

For the fuel system I tried to keep it as simple as possible. I went with a Holly Lp pump and a bosch *044 (higher volume/pressure needed for the S85 engine) Also 2 in line filters and a regulator.

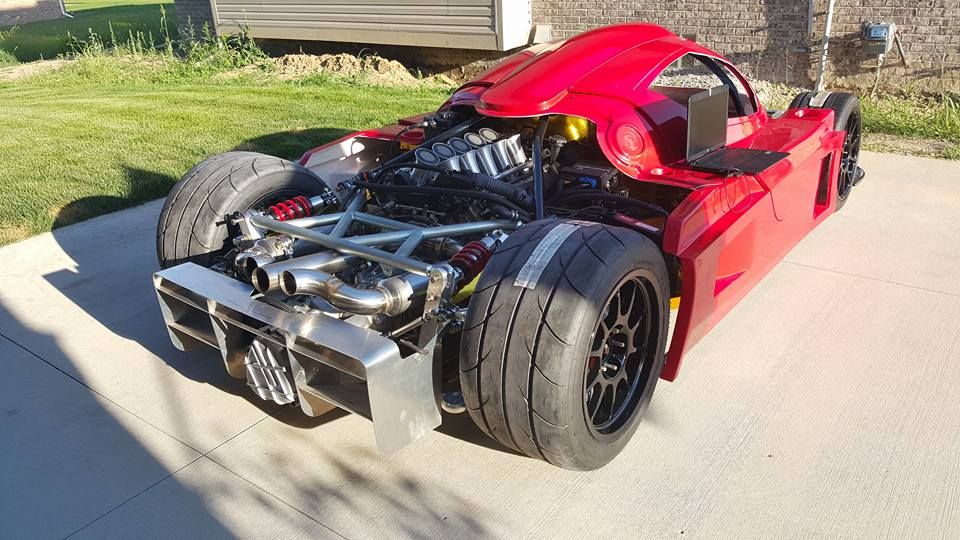

Now for my favorite part. Designing the exhaust system that will deliver the best possible sound from this S85. Being that I live in a quite neighborhood I had to decide on the quietest possible exhaust with the option of having an electronic switch to let his beast roar when I needed it to. I decided on having Burns stainless make custom mufflers for it. I opted for custom 2.5 " cores with 3" outlet mufflers that would serviceable/repackable just be removing the body. I also wanted to install electronic or vacuum QTP electronic control valve. I then decided I would run 4" upper pipes and use reducers to bring it down to 3". *Here are a couple prototype exhaust up pipes.

Here a pic with the muffler tips for a 458 italia. Initially I wanted to do a quad exit like the Pagani Zonda, but due to limited room I stuck with the 3 pipe exit.

I have many more pictures to upload just ran out of time. Next pictures I upload will include body fitment and interior.