You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Front passenger coil over?

- Thread starter EFNFAST

- Start date

Craig Gillingham

Banned because I can't follow the forum rules.

The only 'unusual' thing I can think of in the back is that when I jack it up from the middle, the passenger tire leaves the ground several strokes before the driver side does.

this is where things get technical as its all to do with the cars balance and weight ditribution to the pivot point where your jacking from..

Craig Gillingham

Banned because I can't follow the forum rules.

well as youve assumed the car is perfectly weighted, the jack is exactly in the middle, the floor is pefectly flat and the front shocks are perfectly attributed then maybe its a bent jack

get a bent jack gauge from home depot...?

get a bent jack gauge from home depot...?

lol

to take the rear out of the equation I put 4 1/2'' worth of blocks under it. Oddly though now when I jack the rear the tires both leave the ground at the same exact time. So that's another question - if I measure 4 1/2'' in the rear with both coilovers installed, the driver side always lifts several pumps after the passenger. If I remove the coilover and just place blocks, they both move evenly.

Unfortunately didn't really do anything with the front. For example, I set the number of threads showing equal, driver side reads 4 1/2. Passenger side reads 4 1/4. I chase the passenger side up to 4 1/2, and now my driver is 4 3/4(ish). Hmm.

It also seems to matter where I'm measuring chassis height from - if I measure at the front corner of the chassis (infront of the shock) I get 1/4'' difference with equal thread counts. If I follow (from that front point) the chassis back several inches to the first bend and re-measure, now I'm roughly 1/8 difference. Maybe I'm measuring at the wrong place (forward most edge of the chassis, which is after the coilover). I don't think ti should matter?

to take the rear out of the equation I put 4 1/2'' worth of blocks under it. Oddly though now when I jack the rear the tires both leave the ground at the same exact time. So that's another question - if I measure 4 1/2'' in the rear with both coilovers installed, the driver side always lifts several pumps after the passenger. If I remove the coilover and just place blocks, they both move evenly.

Unfortunately didn't really do anything with the front. For example, I set the number of threads showing equal, driver side reads 4 1/2. Passenger side reads 4 1/4. I chase the passenger side up to 4 1/2, and now my driver is 4 3/4(ish). Hmm.

It also seems to matter where I'm measuring chassis height from - if I measure at the front corner of the chassis (infront of the shock) I get 1/4'' difference with equal thread counts. If I follow (from that front point) the chassis back several inches to the first bend and re-measure, now I'm roughly 1/8 difference. Maybe I'm measuring at the wrong place (forward most edge of the chassis, which is after the coilover). I don't think ti should matter?

Summary time - because I know something unusual is going on, I just can't pinpoint it.

-Removed rear coilovers, on 4 1/2'' blocks on each side in the rear

-Swapped entire coil-over units side-to-side, no difference

-Removed tie rod/uca/coilover and moved LCAs by hand - no binding or sticking anywhere

Here's what I've observed from the coilover though:

-Start by making each one even (e.g., 5threads showing on each). Passenger side is roughly 1/4'' lower than the driver side. (measured from front most corner of the chassis on each side)

-If I leave passenger side alone, and adjust driver side, it moves as expected (e.g., adjustment ring up several turns, ride height raises like 1/4'', adjustment ring down, ride height drops like 1/4'')

-If I leave the driver side alone and adjust passenger side, it barely moves. Say I start at 4''. Adjust several turns (the equivilent of 1/4'' increment in driver side) and it moves like 1/8. If that.

What's weird though is that it seems like the passenger side is totally dependent on the driver side. For example, if I set the adjustment ring all the way down on the pass side and all the way up on the driver side, I can get a (roughly) 5''(d)/3 1/2''(p) ride height. However, if I set the adjustment ring all the way down on the driver and all the way up on the passenger, I can get, maybe like a 3 1/2(d) and a 4 1/4(p). Alternatively, if I set the driver side coil-over to roughly 4 1/2'' with the adjustment ring almost all the way to the top on the passenger side I can getit close to 4 1/2''. If i raise the driver side to 5'', then in the exact same position the passenger side was 4 1/2 it's now closer to 5''. Maybe I'm not wording this right, but it's like the exact same position on the passenger side can become multiple ride heights depending strictly on what the driver side is....it's almost like the passenger side is dependent on the driver side, but the driver side is independent of the passenger side.....

But again we get back to the same basic issue - the driver acts as expected (turns ont he adjustment ring become reflected in the ride height), passenger side does not act as expectd (turns on the adjustment arn't reflected in changes in ride height).

-Removed rear coilovers, on 4 1/2'' blocks on each side in the rear

-Swapped entire coil-over units side-to-side, no difference

-Removed tie rod/uca/coilover and moved LCAs by hand - no binding or sticking anywhere

Here's what I've observed from the coilover though:

-Start by making each one even (e.g., 5threads showing on each). Passenger side is roughly 1/4'' lower than the driver side. (measured from front most corner of the chassis on each side)

-If I leave passenger side alone, and adjust driver side, it moves as expected (e.g., adjustment ring up several turns, ride height raises like 1/4'', adjustment ring down, ride height drops like 1/4'')

-If I leave the driver side alone and adjust passenger side, it barely moves. Say I start at 4''. Adjust several turns (the equivilent of 1/4'' increment in driver side) and it moves like 1/8. If that.

What's weird though is that it seems like the passenger side is totally dependent on the driver side. For example, if I set the adjustment ring all the way down on the pass side and all the way up on the driver side, I can get a (roughly) 5''(d)/3 1/2''(p) ride height. However, if I set the adjustment ring all the way down on the driver and all the way up on the passenger, I can get, maybe like a 3 1/2(d) and a 4 1/4(p). Alternatively, if I set the driver side coil-over to roughly 4 1/2'' with the adjustment ring almost all the way to the top on the passenger side I can getit close to 4 1/2''. If i raise the driver side to 5'', then in the exact same position the passenger side was 4 1/2 it's now closer to 5''. Maybe I'm not wording this right, but it's like the exact same position on the passenger side can become multiple ride heights depending strictly on what the driver side is....it's almost like the passenger side is dependent on the driver side, but the driver side is independent of the passenger side.....

But again we get back to the same basic issue - the driver acts as expected (turns ont he adjustment ring become reflected in the ride height), passenger side does not act as expectd (turns on the adjustment arn't reflected in changes in ride height).

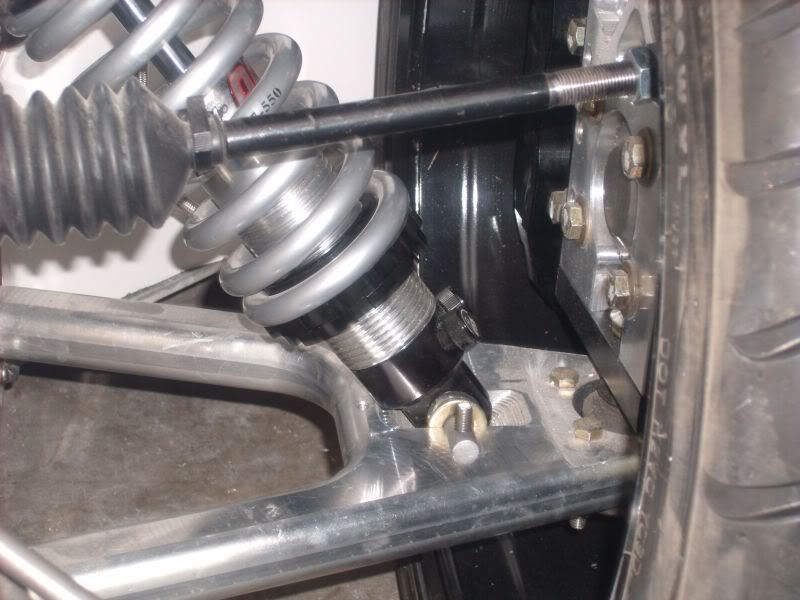

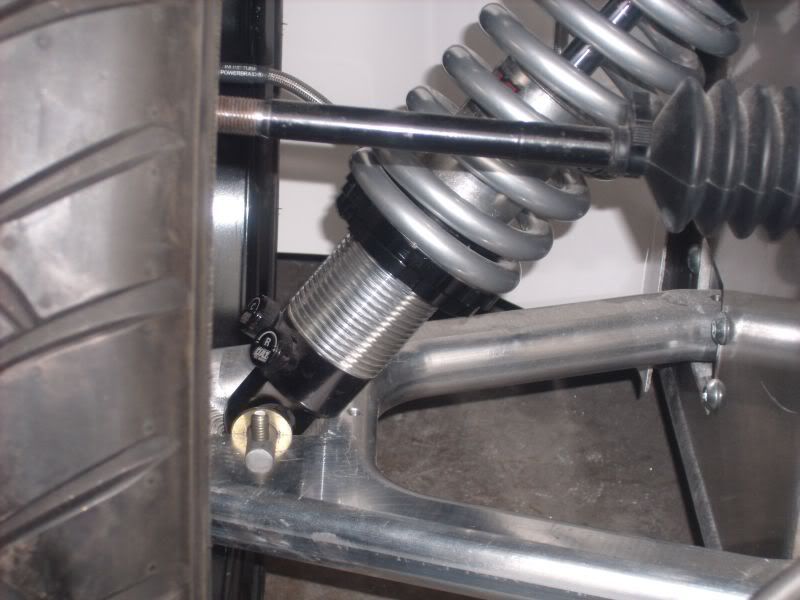

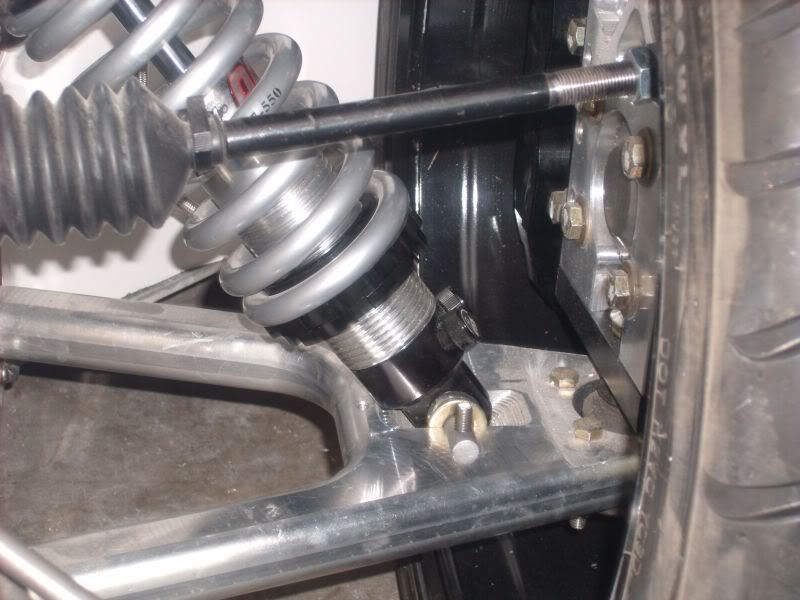

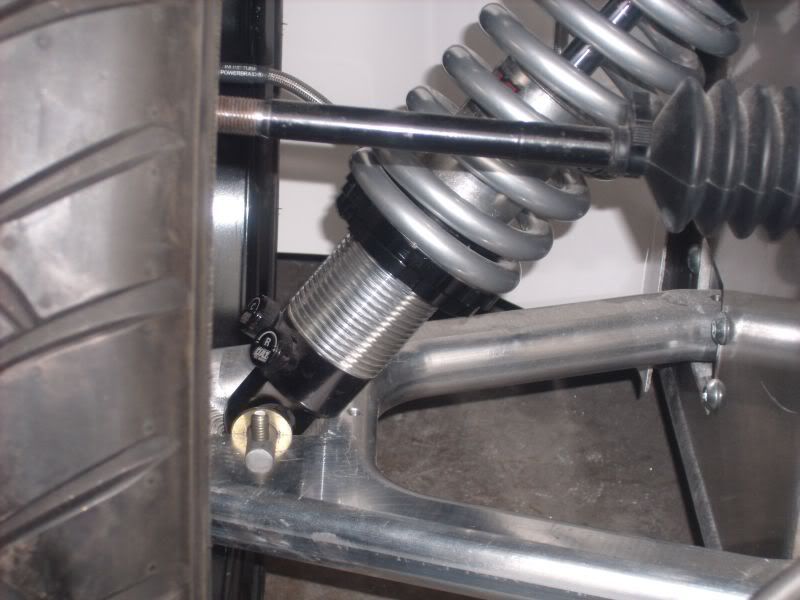

Btw, here's 4 1/2'' even side to side on the chassis with the rear stacked to 4 1/2

ds

ps

Double checked LCAs - no binding anywhere in the range of motion. There's got to be a reason for this - the only 'big' weight item I don't have is the engine, but that should be centered and not effect this. Unless of course it only looks centered and is actually over on the passenger side. But even then, that would effect the rear more than the front.

With no rear in the equation, I've triple checked everything and had everything apart multiple times, there has to be a reason. I don't have access to corner balance scales, or know anybody who does, so there's no point weighing it (not paying 1200 for a set either, heh!)

ds

ps

Double checked LCAs - no binding anywhere in the range of motion. There's got to be a reason for this - the only 'big' weight item I don't have is the engine, but that should be centered and not effect this. Unless of course it only looks centered and is actually over on the passenger side. But even then, that would effect the rear more than the front.

With no rear in the equation, I've triple checked everything and had everything apart multiple times, there has to be a reason. I don't have access to corner balance scales, or know anybody who does, so there's no point weighing it (not paying 1200 for a set either, heh!)

Terry Oxandale

Skinny Man

Have you checked to see if any binding takes place with the shock installed? Raising the right height (according to your photos of the rear) would bring the shock body and the control arm in closer proximity. I wonder if this may be happening on the front somehow. Just a shot in the dark here.

No binding that I see, and no unusual wear patterns on the shock or control arm or rim or anything.

I also tried rolling him to another part of the garage (incase the floor wasn't level enough) and same thing.

With the rear propped up (taken out of the equation) you'd think there would only be 3 possible items that could effect this

- shock

- uca

- lca

Have swapped entire coilover assemblies multiple times, checked uca/lca for binding (absolutely none), so that seems to only leave a weight issue ..... which doesn't make much sense because even if the weight distribution isn't perfect without the engine, I can't see any reason why it would be so far off in the front (when in the rear I can set ride height even +/- 2 threads on the coilover). Hmmmm.

I also tried rolling him to another part of the garage (incase the floor wasn't level enough) and same thing.

With the rear propped up (taken out of the equation) you'd think there would only be 3 possible items that could effect this

- shock

- uca

- lca

Have swapped entire coilover assemblies multiple times, checked uca/lca for binding (absolutely none), so that seems to only leave a weight issue ..... which doesn't make much sense because even if the weight distribution isn't perfect without the engine, I can't see any reason why it would be so far off in the front (when in the rear I can set ride height even +/- 2 threads on the coilover). Hmmmm.

Howard Jones

Supporter

Check to see that both shocks act the same way with:

1. Off car on bench

2. Springs off

3. Compression adjustment full stiff/ rebound full soft

4. Compression adj full soft/ rebound full soft

Stroke the shocks by hand and see if you have any difference in dampening

Then check a few settings in the middle of range, I still think it could be a stuck valve internally. Could it be a stuck valve in the opposite side rear shock?

1. Off car on bench

2. Springs off

3. Compression adjustment full stiff/ rebound full soft

4. Compression adj full soft/ rebound full soft

Stroke the shocks by hand and see if you have any difference in dampening

Then check a few settings in the middle of range, I still think it could be a stuck valve internally. Could it be a stuck valve in the opposite side rear shock?

Alex:

This seems like a school geometry problem to me.

When comparing the left and right sides, are both sides hardware measurements identical? The LCA, shock/spring assembly and frame create a triangle. If you have to raise the collar on the shock more on one side versus the other, it seems as if it is trying to compensate for something else being off.

In the attached photo, are the sections A, B and C the same measurements on both sides? If you are lengthening one shock more than the other your section A, the distance from the upper and lower shock connecting points, is likely not the same.

If the measurements on both sides are not the same, try and determine what is causing the difference, for example, is the frame/chassis square?

If the measurements are equal on both sides, it may be a difference on the spring rates, ie the passanger side is sagging more than the driver side and you therefore need to raise the collar to compensate.

If all this does not apply, then I apologize and you can disregard it. I count beans as my day job.

Chris

This seems like a school geometry problem to me.

When comparing the left and right sides, are both sides hardware measurements identical? The LCA, shock/spring assembly and frame create a triangle. If you have to raise the collar on the shock more on one side versus the other, it seems as if it is trying to compensate for something else being off.

In the attached photo, are the sections A, B and C the same measurements on both sides? If you are lengthening one shock more than the other your section A, the distance from the upper and lower shock connecting points, is likely not the same.

If the measurements on both sides are not the same, try and determine what is causing the difference, for example, is the frame/chassis square?

If the measurements are equal on both sides, it may be a difference on the spring rates, ie the passanger side is sagging more than the driver side and you therefore need to raise the collar to compensate.

If all this does not apply, then I apologize and you can disregard it. I count beans as my day job.

Chris

Chris,

Alex has checked all of the above and they are correct left to right...he has stated in other posts that the springs and shocks are all matched...the pick up/mounting points are all equal....the suspension locations are all waterjetted locations and the programme has not been changed.

I wonderered if the rod ends were all screwed in the same amount ..but seems they are also equal..

I too am at a loss ...as we dont have this issue on any chassis in the shop..

Alex has checked all of the above and they are correct left to right...he has stated in other posts that the springs and shocks are all matched...the pick up/mounting points are all equal....the suspension locations are all waterjetted locations and the programme has not been changed.

I wonderered if the rod ends were all screwed in the same amount ..but seems they are also equal..

I too am at a loss ...as we dont have this issue on any chassis in the shop..

Alex,

in your first post, paragraph 3, you say

Also, it's almost like my passenger spring is binding and wedging itself onto the spring hat. On the driver side, if I put the adjustment&lock rings in the middle of the shock body thread and jack it up, the spring and spring hat become loose and flop around (as they should). On the passenger side, at the same rough point (half-way) the spring hat is still tight against the top of the shock, and the spring is tight against both the hat and adjustment ring. It only loosens up and freely flops around (with the spring hat) when I get down to like 1/4 of the thread remaining (roughly).

are you saying,.... the spring adjustement is the same on both shocks, but when you jack the car up, (so there is no weight on the wheels)the driver side spring, is not compressed, but the passenger side spring is compressed ??

mick

in your first post, paragraph 3, you say

Also, it's almost like my passenger spring is binding and wedging itself onto the spring hat. On the driver side, if I put the adjustment&lock rings in the middle of the shock body thread and jack it up, the spring and spring hat become loose and flop around (as they should). On the passenger side, at the same rough point (half-way) the spring hat is still tight against the top of the shock, and the spring is tight against both the hat and adjustment ring. It only loosens up and freely flops around (with the spring hat) when I get down to like 1/4 of the thread remaining (roughly).

are you saying,.... the spring adjustement is the same on both shocks, but when you jack the car up, (so there is no weight on the wheels)the driver side spring, is not compressed, but the passenger side spring is compressed ??

mick

Get two pieces of alloy or steel tube ( even 1/8" wall PVC drain pipe might work) slightly larger in ID than your front coil ID, make them about as long as the current fitted length of the front springs , cut the ends nice & square so they wont cause a bind on the spring seats/shocks. Fit these in place of the springs & check for the same problem... if its still there its in the dampers/suspension, if its gone its the front spring being improperly wound or treated & causing a bind in the damper under load...

BTW, this running springs that can fall off the seats at externsion & damage threads etc is a bit silly, you guys never used anti rattle or two step spring kits

BTW, this running springs that can fall off the seats at externsion & damage threads etc is a bit silly, you guys never used anti rattle or two step spring kits

As far as I can tell (from measurements, checking for binding, rod ends in/out, pretty much every suggestion given above, etc... etc...) everything is pretty much equal.

It seems the best course of action is just to wait for the engine, put it in, and see if the final weighting effects it. (in terms of how it's balanced, obviously more weight = adjustment back up).

Thinking about it now, that does seem to make sense - I remember when doing the ride height on my cobra the rear shocks were really unevenly balanced before the engine was in, and then roughly evened out after the engine went in. So my initial assumption of engine in centre = no effect side/side in the front may not have been correct.

I doubt most people are scuttling around the car trying to set ride height before having their major componentry in, just so they can see wheelwell arch clearance, heh. What can I say, I'm special like that :drunk:

It seems the best course of action is just to wait for the engine, put it in, and see if the final weighting effects it. (in terms of how it's balanced, obviously more weight = adjustment back up).

Thinking about it now, that does seem to make sense - I remember when doing the ride height on my cobra the rear shocks were really unevenly balanced before the engine was in, and then roughly evened out after the engine went in. So my initial assumption of engine in centre = no effect side/side in the front may not have been correct.

I doubt most people are scuttling around the car trying to set ride height before having their major componentry in, just so they can see wheelwell arch clearance, heh. What can I say, I'm special like that :drunk:

I think you need too go back to basics on this. I have experience in setting up oval racing cars and I have a method that I use on a new car, although slightly different for non symetrical cars I suggest the following.

Remove all spring/shock units from the car,

Place the car on blocks at the desired height.( making sure they are in the same place symetrically left to right)

Place a spirit level ( preferably a digital inclinometer) on the chassis from Drivers/passengers side ( not front too back)

Car should be level and touching all blocks. ( if not, floor is not level or car is twisted/bent)

Then measure the distance between where the shock/springs mount on.( this should be the same left to right)

If it is the same then the problem is with the shock/spring units.

If it is not the same but level and touching all blocks then there is something wrong with the Suspension geometry, more camber on one side? caster? etc etc

Hope this helps, Let us know

Ideally I would set this up on my scales but we usually run about 54% of the total car weight on the Left hand side anyway ( Your car would turn left very well!!))

Remove all spring/shock units from the car,

Place the car on blocks at the desired height.( making sure they are in the same place symetrically left to right)

Place a spirit level ( preferably a digital inclinometer) on the chassis from Drivers/passengers side ( not front too back)

Car should be level and touching all blocks. ( if not, floor is not level or car is twisted/bent)

Then measure the distance between where the shock/springs mount on.( this should be the same left to right)

If it is the same then the problem is with the shock/spring units.

If it is not the same but level and touching all blocks then there is something wrong with the Suspension geometry, more camber on one side? caster? etc etc

Hope this helps, Let us know

Ideally I would set this up on my scales but we usually run about 54% of the total car weight on the Left hand side anyway ( Your car would turn left very well!!))

I doubt most people are scuttling around the car trying to set ride height before having their major componentry in, just so they can see wheelwell arch clearance, heh. What can I say, I'm special like that :drunk:

Thats partly why I suggested the tubes ( steel/alloy/PVC ) whatever, I dont even think about springs etc until the whole cars ready for them, & even then if your building for someone else you need to take an educated guess for the initial setup as drivers & end use are never the same...

Place the car on blocks at the desired height.( making sure they are in the same place symetrically left to right)

Place a spirit level ( preferably a digital inclinometer) on the chassis from Drivers/passengers side ( not front too back)

Car should be level and touching all blocks. ( if not, floor is not level or car is twisted/bent)

This is what I would do aswell. If you have swapped shocks around the car and the problem stays in the one corner then I would be thinking that the chassis is bent. The blocks will clear this up straight away and maybe hours of head scratching.

marc

Lifetime Supporter

Alex,

It may not apply to you, but you are not starting with a perfectly level surface. Nor is the car weighted right yet. By the way you can scale your car with 1 scale if you want to but you are not ready for that yet. If you have physically stroked the suspension without the shocks and springs in place, then with just the shocks. measured the length of the springs for equality. I would move forward from here to other more pressing installation items. If the issue is wheel arch clearance you can buy some light weight springs to play or JacMacs deal. My money says while you are building check measurements to be close with play, then when you have all the car stuff in there, while you are waiting for some irrelavant item to come in then fully measure, document, then align. I think someone showed some serious measuring in a build log I read. If there is bind you will have found it long ago.

Good hunting.

Oh one other thing. I get circle track racing for one of my other racing habits and the have big time info on car setups albeit for (wait for it) circle racing. the ideas are the same. There are some great info in some of the Steve Smith motorsports books too.

Okay so I can be a book worm. but with setting up ride height its good to dream.

Good luck in your build... you make me go work on mine.

Marc

It may not apply to you, but you are not starting with a perfectly level surface. Nor is the car weighted right yet. By the way you can scale your car with 1 scale if you want to but you are not ready for that yet. If you have physically stroked the suspension without the shocks and springs in place, then with just the shocks. measured the length of the springs for equality. I would move forward from here to other more pressing installation items. If the issue is wheel arch clearance you can buy some light weight springs to play or JacMacs deal. My money says while you are building check measurements to be close with play, then when you have all the car stuff in there, while you are waiting for some irrelavant item to come in then fully measure, document, then align. I think someone showed some serious measuring in a build log I read. If there is bind you will have found it long ago.

Good hunting.

Oh one other thing. I get circle track racing for one of my other racing habits and the have big time info on car setups albeit for (wait for it) circle racing. the ideas are the same. There are some great info in some of the Steve Smith motorsports books too.

Okay so I can be a book worm. but with setting up ride height its good to dream.

Good luck in your build... you make me go work on mine.

Marc

As far as I can tell (from measurements, checking for binding, rod ends in/out, pretty much every suggestion given above, etc... etc...) everything is pretty much equal.

It seems the best course of action is just to wait for the engine, put it in, and see if the final weighting effects it. (in terms of how it's balanced, obviously more weight = adjustment back up).

Thinking about it now, that does seem to make sense - I remember when doing the ride height on my cobra the rear shocks were really unevenly balanced before the engine was in, and then roughly evened out after the engine went in. So my initial assumption of engine in centre = no effect side/side in the front may not have been correct.

I doubt most people are scuttling around the car trying to set ride height before having their major componentry in, just so they can see wheelwell arch clearance, heh. What can I say, I'm special like that :drunk:

Alex mate,

I too have set up the suspension without engine etc etc... This was recommended by a LOT of people on here, as you need all your geometry right in order to get the best fit for the body. IMHO, you've done the right thing here. Whacking in the engine will mean some adjustment (obviously), but without doing it now, how can you tell your'e wheels sit correctly in the arches in all three dimensions?

Cheers,

Graham.

Similar threads

- Replies

- 15

- Views

- 1K

- Replies

- 10

- Views

- 2K

- Replies

- 25

- Views

- 5K

- Replies

- 5

- Views

- 4K