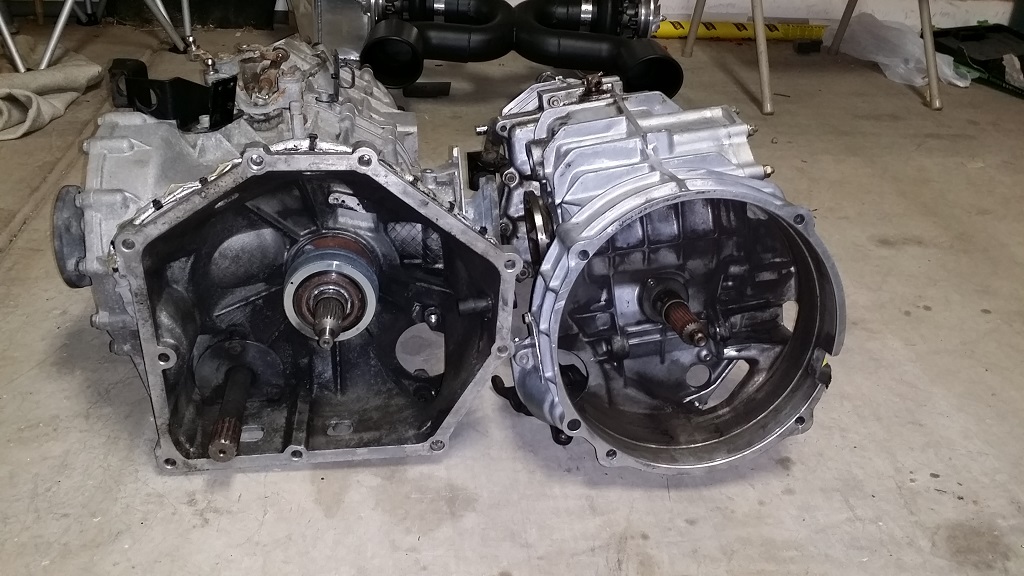

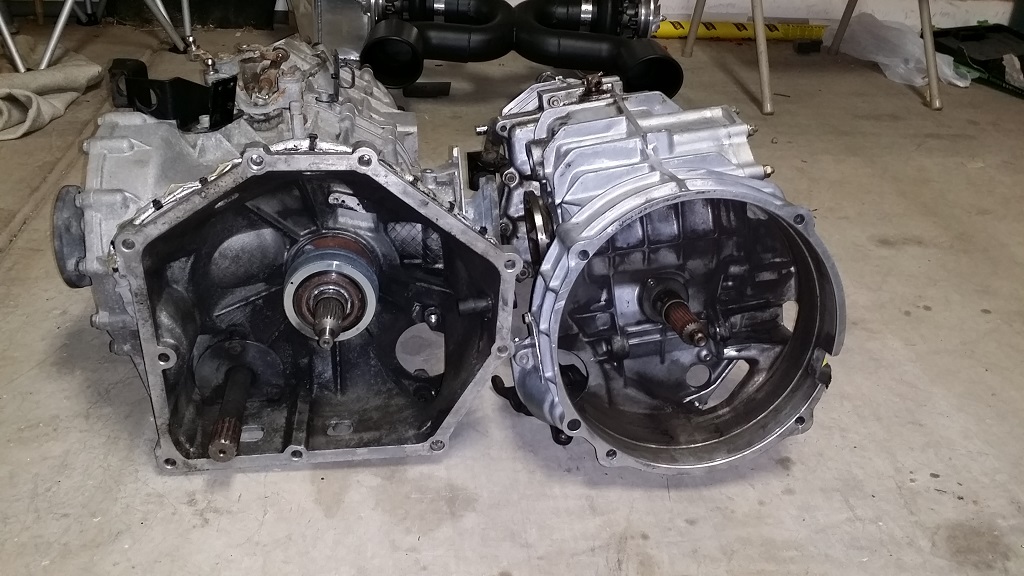

Thought I would share a couple pics that pertain to the adaptation and the application of the Graziano. You may notice that the flywheel has an 8 bolt pattern, and not the typical 6. That is because of the LSX forged crank. If anyone needs this pattern, let me know and I'd be happy to share it. It was a bit rough trying to get it from anyone, so I had to reverse engineer another flywheel I had for the G50. Thankfully it worked.

Here is a shot of the flywheel that's been modified to work with the SPEC billet clutch and has been outfitted with a serviceable friction plate so the flywheel never needs to be resurfaced or replaced. The SPEC clutch actually is fully serviceable, so all friction surfaces, intermediate plates and whatnot can be replaced, resulting in an overall savings in exchange for a little more expense up front.

I also changed out the slave cylinder/release bearing from the old revision to the new. I figured that would be a good idea while I had the trans out again and the newer revision is not only better, but substantially cheaper than the original. ($700 instead of $3100)

You can see the old one on the left (the large silver ring around the input shaft).

Here it is removed (you can see the inlet and outlet ports with the o-rings, which you should replace while it's apart. My old ones were pretty brittle.

and here is the new one installed:

The process didn't take very long, but there's not many pictures on the web, even with the Lambo forums as most of them have their mechanic do it, so I thought I'd pass it along.

Here is a shot of the flywheel that's been modified to work with the SPEC billet clutch and has been outfitted with a serviceable friction plate so the flywheel never needs to be resurfaced or replaced. The SPEC clutch actually is fully serviceable, so all friction surfaces, intermediate plates and whatnot can be replaced, resulting in an overall savings in exchange for a little more expense up front.

I also changed out the slave cylinder/release bearing from the old revision to the new. I figured that would be a good idea while I had the trans out again and the newer revision is not only better, but substantially cheaper than the original. ($700 instead of $3100)

You can see the old one on the left (the large silver ring around the input shaft).

Here it is removed (you can see the inlet and outlet ports with the o-rings, which you should replace while it's apart. My old ones were pretty brittle.

and here is the new one installed:

The process didn't take very long, but there's not many pictures on the web, even with the Lambo forums as most of them have their mechanic do it, so I thought I'd pass it along.