You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Starter Not Engaging

- Thread starter Bill D

- Start date

Dutton

Lifetime Supporter

Bill,

How frustrating to be THIS close to the finish line! By 'not engaging' do you means that:

• the starter isn't turning over OR

• the starter is turning but the bendix isn't moving the starter gear towards the flywheel OR

• the starter is turning and the bendix is working fine but the starter assembly is too far away from the flywheel?

T.

How frustrating to be THIS close to the finish line! By 'not engaging' do you means that:

• the starter isn't turning over OR

• the starter is turning but the bendix isn't moving the starter gear towards the flywheel OR

• the starter is turning and the bendix is working fine but the starter assembly is too far away from the flywheel?

T.

Rob

Lifetime Supporter

Hey Bill,

Sorry to tell ya, but believe you have the wrong flywheel..... I know...I know...Kennedy told you that the bell housing was for a 157 tooth wheel...right? Same for me, once it showed up I figured it out. Amazing that they don't know what they are selling. I used a 164 tooth on mine, and we have the same set ups. Sorry man.....:cry:

Sorry to tell ya, but believe you have the wrong flywheel..... I know...I know...Kennedy told you that the bell housing was for a 157 tooth wheel...right? Same for me, once it showed up I figured it out. Amazing that they don't know what they are selling. I used a 164 tooth on mine, and we have the same set ups. Sorry man.....:cry:

Rob

Lifetime Supporter

As I said.......SORRY man.... I didn't really want to tell you the input.... I even pulled all my files to confirm what I thought I remembered before I responded.

I wouldn't pull the motor, just the transaxle. It would be quicker than disconnecting all the plumbing and bits.....

Feel free to call if you want to discuss.

I wouldn't pull the motor, just the transaxle. It would be quicker than disconnecting all the plumbing and bits.....

Feel free to call if you want to discuss.

RAM-1505 from Summit $250

CTF-700240 centerforce $287 from Summit

CTF-700240 centerforce $287 from Summit

Ron McCall

Supporter

I can not find a 164 tooth flywheel with 28oz external weights?

I have a Mcleod flywheel. I think it has provisions for weights to be added if needed.

Give them a call.

Ram -1505 weighs 33lb, should dampen out the vibes . WTF do you need a 164t flywheel anyway, just get an early sandwich plate to match the 157t flywheel & drill /tap the adaptor to suit, might have to add a blob of alloy with the tig for the lower bolt in a worst case scenario, but still gonna cost lots less than a new flywheel plus you retain the lower MOI of the small flywheel, more ground clearance etc, etc.

. WTF do you need a 164t flywheel anyway, just get an early sandwich plate to match the 157t flywheel & drill /tap the adaptor to suit, might have to add a blob of alloy with the tig for the lower bolt in a worst case scenario, but still gonna cost lots less than a new flywheel plus you retain the lower MOI of the small flywheel, more ground clearance etc, etc.

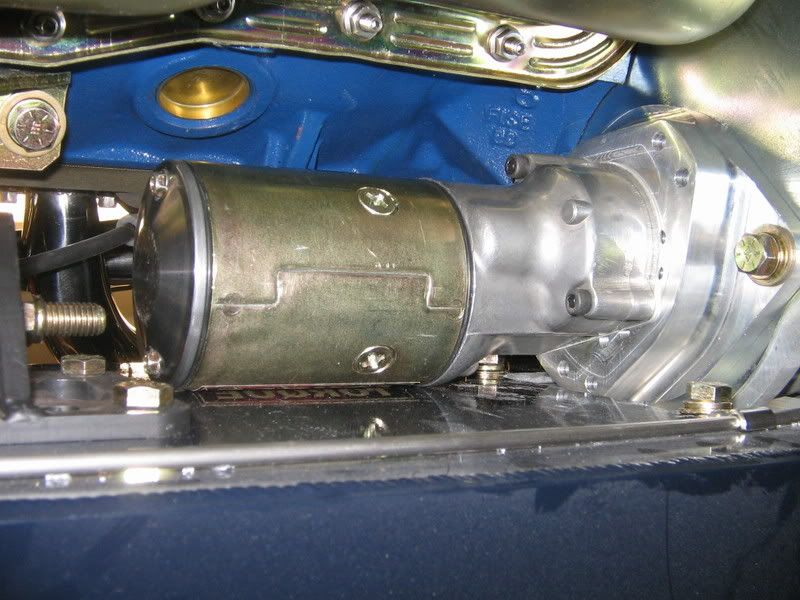

BEFORE you do anything drastic ensure that you have the correct starter ( or more correctly the right end housing fitted to the starter )- The starter for a 164t manual flywheel has the pinion set further forward due to different ring gear placement than the 164t auto or 157t manual/auto versions. Other than that starters should be identical.

BEFORE you do anything drastic ensure that you have the correct starter ( or more correctly the right end housing fitted to the starter )- The starter for a 164t manual flywheel has the pinion set further forward due to different ring gear placement than the 164t auto or 157t manual/auto versions. Other than that starters should be identical.

Last edited:

JM

I wish it were that simple. The starter mounts to holes in the bellhousing.

Do you think I could redrill the bellhousing?

Bill, that is exactly what I am suggesting, the sandwich plate ( the 0.060" steel plate fitted between engine block & bellhousing on all early SBF ) has the location hole for the starter in it, obtain one of these from a 65 thru whatever SBF with the 157t flywheel/flexplate, auto or manual and use it as a drilling template for the new bolt holes in the bell housing/adapter by simply sitting it on the bellhousing and located with two 1/2" bolts in the factory dowel holes. As mentioned earlier the lower starter attachment hole might exit in fresh air/maybe not, but a blob of alloy weld would be sufficient to tap into.

BTW the sandwich plate should be used in order to locate the starter correctly in relation to the ring gear- the bolts are not meant to do this, all you guys that dont use one are asking for trouble-- so buy a sandwich plate and use it, save a lot of aggro later, let me know if you need a pic put up, have all three types down in the shed, becomes self explanatory when you see them all stacked on top of one another. Gotta go pull a 289 to bits for appraisal soon so will take camera with me-hate it when work intrudes on sunday afternoons.

Bill, pics of two different sandwich plates and three ring gear diameters. Sandwich plate you require is on top and would be from any early 6 bolt 289/302 either manual or auto.

Three Flex Plates are 164t bottom, 157t middle, & cant remember how many for smallest which is for 50oz mustang/capri models.

Looks like you may need to add a blob of alloy weld for bottom bolt if your bell is same as Marks in pic above or possibly you could drill for longer bolt to go right thru adaptor.

Three Flex Plates are 164t bottom, 157t middle, & cant remember how many for smallest which is for 50oz mustang/capri models.

Looks like you may need to add a blob of alloy weld for bottom bolt if your bell is same as Marks in pic above or possibly you could drill for longer bolt to go right thru adaptor.

Last edited:

Similar threads

- Replies

- 17

- Views

- 1K

- Replies

- 12

- Views

- 1K

- Replies

- 11

- Views

- 2K