A little bit of engineering that I did on the first GTD 40 build about ten years ago

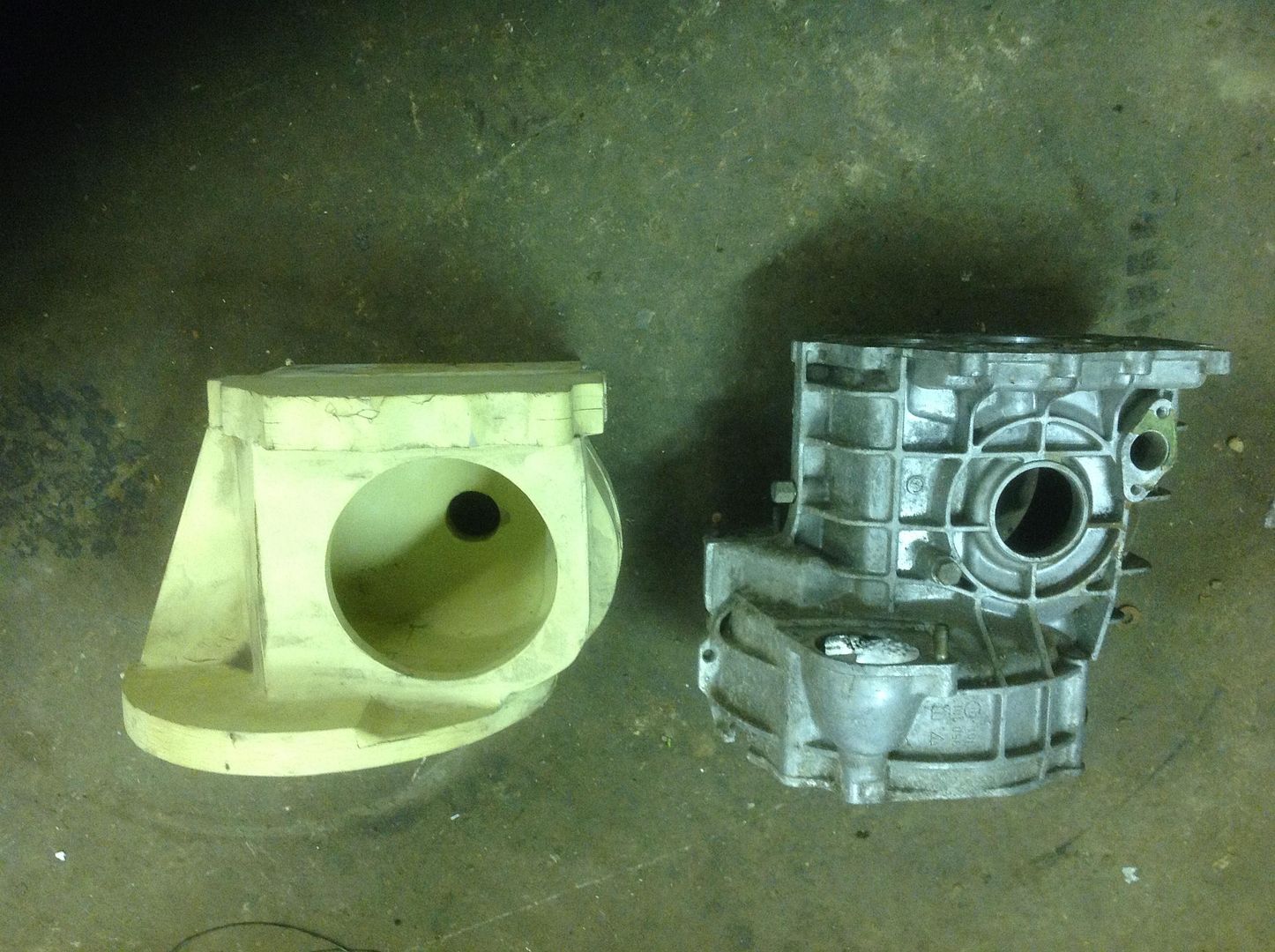

We were throwing ideas about regarding transaxles for the 40 and decided to go for the G50. I did not like the look of the adapter plates and was not happy with running it upside down because of the driveshaft angles. I made a split mold and had cast a housing that would allow the diff to be installed on the other side of the pinion, the same mold was made to take a separate bellhousing which in turn could then take a normal ford flywheel + full size clutch with the starter in the normal place. The Casting was made 30mm plus thick so that all the ribbing could be machined on the outside afterwards . it seems like a lot of work but to cast the ribbing on this type of mold would have been a lot more work. The casting was also machined to take the original G50 side cover. With all the machining done you can barely tell it apart from a factory job. Also runs dead straight driveshafts as installed.

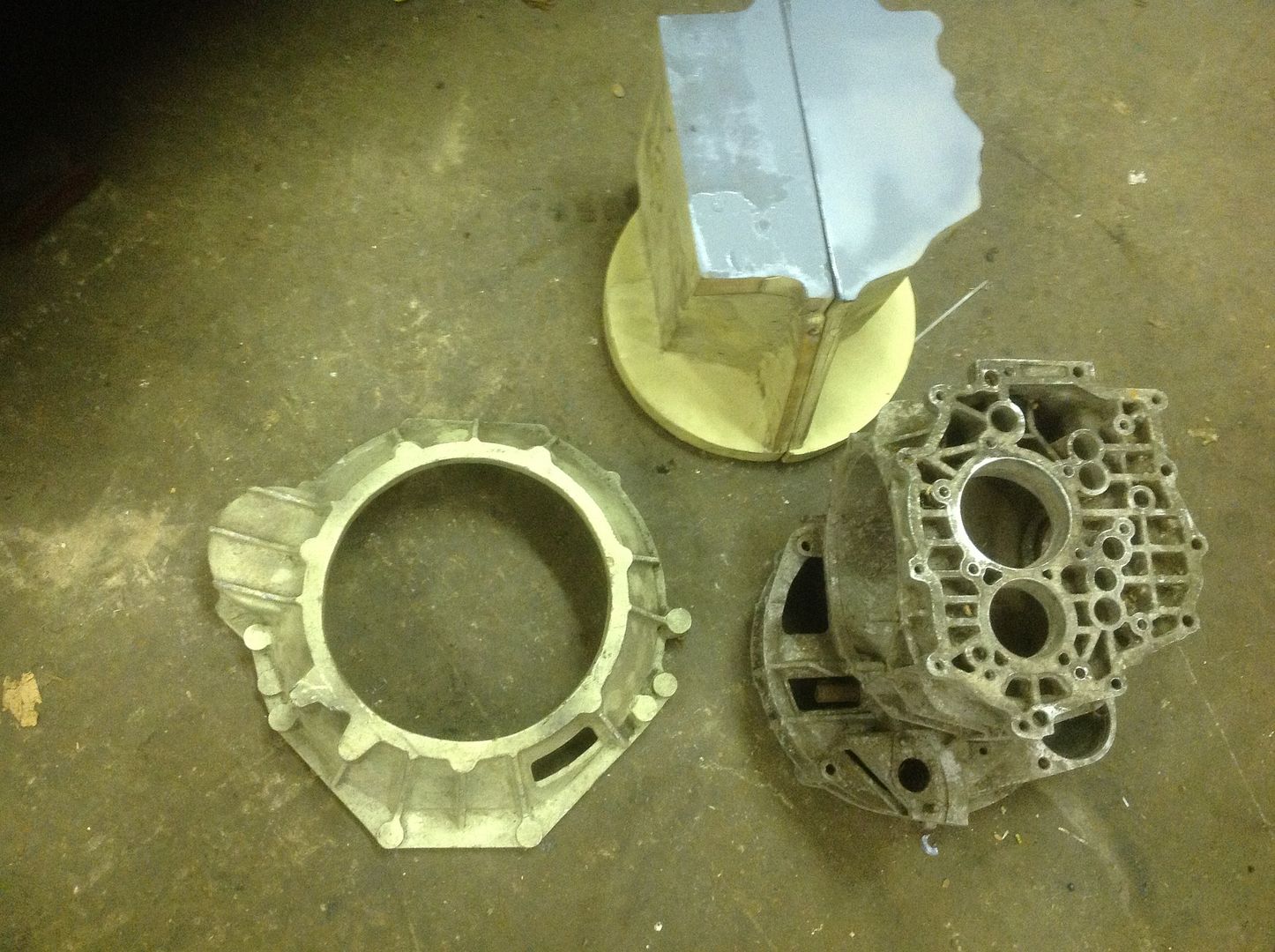

The flange of the diff housing was machined to take the same bolt pattern as the pantera zf unit. Below is the mold made for the bellhousing which is just a filled and painted pantera unit.

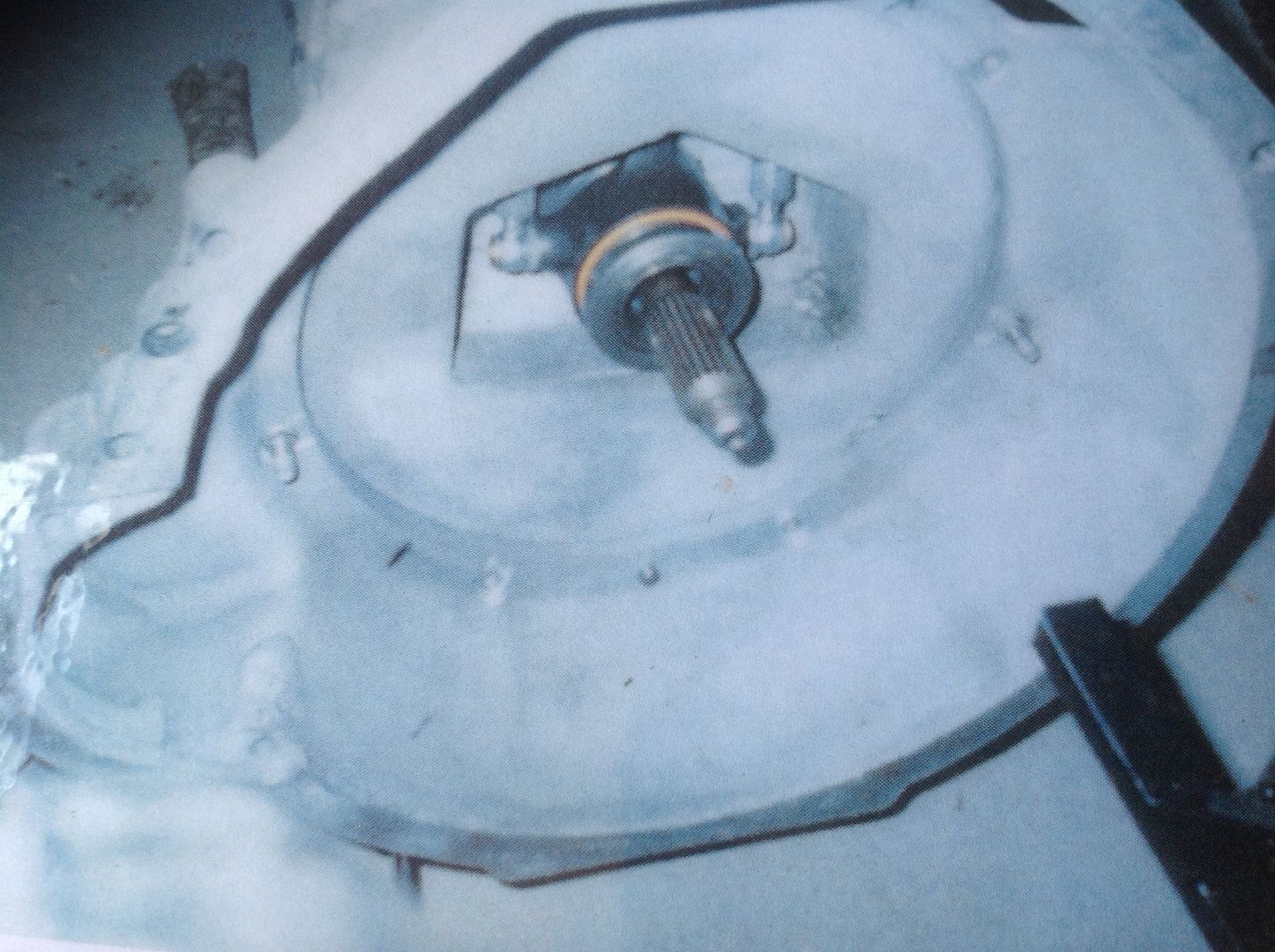

The clutch drive plate was from a 928 porsche and the release bearing was a mcleod hydraulic just to keep it simple. I will get some pictures of it in the car in its finished guise with all the ribs machined on. Its been in the car ten years now with now problems. Only the one was cast because a zf turned up for the second build but without that I would be doing another one.

Bob

Edit .G50 diff housing up for grabs if anyone needs it.

We were throwing ideas about regarding transaxles for the 40 and decided to go for the G50. I did not like the look of the adapter plates and was not happy with running it upside down because of the driveshaft angles. I made a split mold and had cast a housing that would allow the diff to be installed on the other side of the pinion, the same mold was made to take a separate bellhousing which in turn could then take a normal ford flywheel + full size clutch with the starter in the normal place. The Casting was made 30mm plus thick so that all the ribbing could be machined on the outside afterwards . it seems like a lot of work but to cast the ribbing on this type of mold would have been a lot more work. The casting was also machined to take the original G50 side cover. With all the machining done you can barely tell it apart from a factory job. Also runs dead straight driveshafts as installed.

The flange of the diff housing was machined to take the same bolt pattern as the pantera zf unit. Below is the mold made for the bellhousing which is just a filled and painted pantera unit.

The clutch drive plate was from a 928 porsche and the release bearing was a mcleod hydraulic just to keep it simple. I will get some pictures of it in the car in its finished guise with all the ribs machined on. Its been in the car ten years now with now problems. Only the one was cast because a zf turned up for the second build but without that I would be doing another one.

Bob

Edit .G50 diff housing up for grabs if anyone needs it.

Last edited: