Hi Thomas

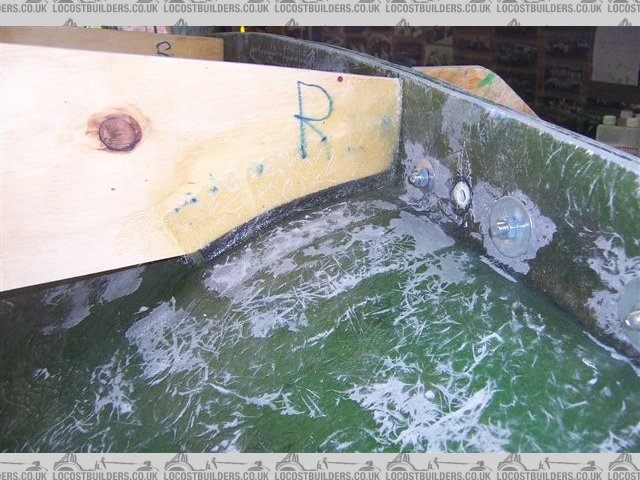

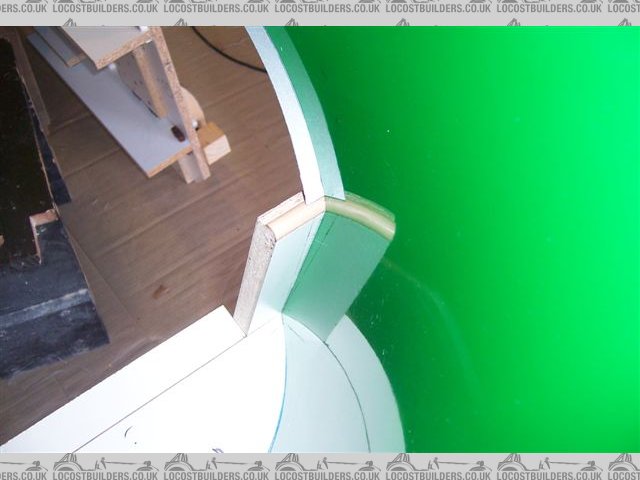

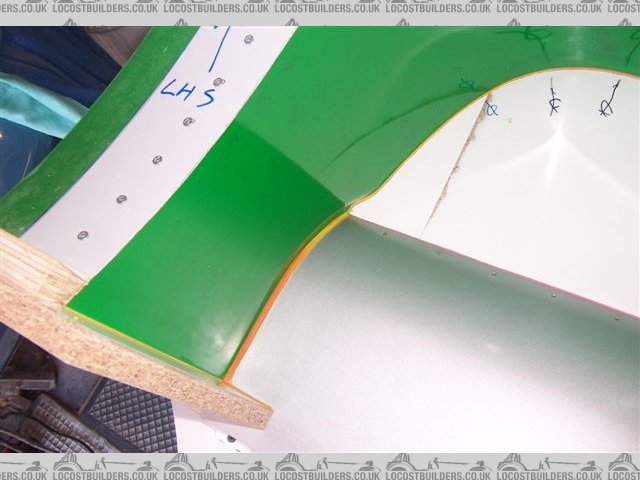

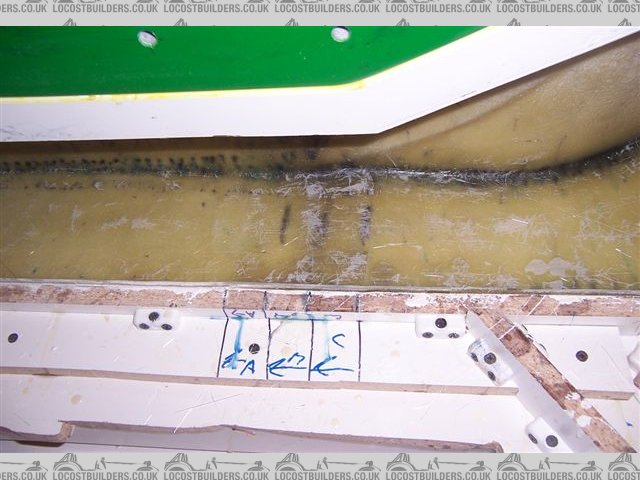

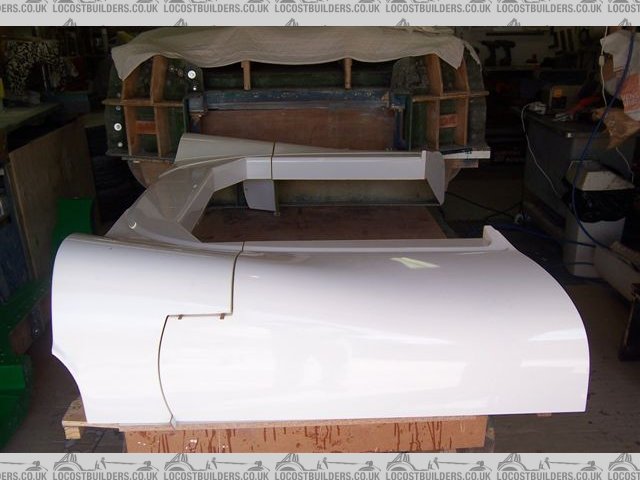

Thanks for the interest. Over the last few weeks it has been difficult to find much garage time but I can report that now the top section of the tail mold is done, the bracing is bonded on, all the fastening bolts through the flanges are fitted and finally I can say the body molds are finished!! Only took 1 week short of 6 years since starting to build the pattern.

Have a good Christmas and New Year All!

Cheers

Fred W B

Thanks for the interest. Over the last few weeks it has been difficult to find much garage time but I can report that now the top section of the tail mold is done, the bracing is bonded on, all the fastening bolts through the flanges are fitted and finally I can say the body molds are finished!! Only took 1 week short of 6 years since starting to build the pattern.

Have a good Christmas and New Year All!

Cheers

Fred W B

Last edited: