First the pics and then the explanation of the shots.

17" is the outside of my frame.

38" is the

outside of the horizontal bar including the mount for the body. The tabs are about 4mm. This bar is square to the link going down to the frame

36" is the outside measurement of the link to the top of the cross engine mount.

15" is the bottom link and is measured from its weld to the horizontal bar to where it meets the tab on the frame.

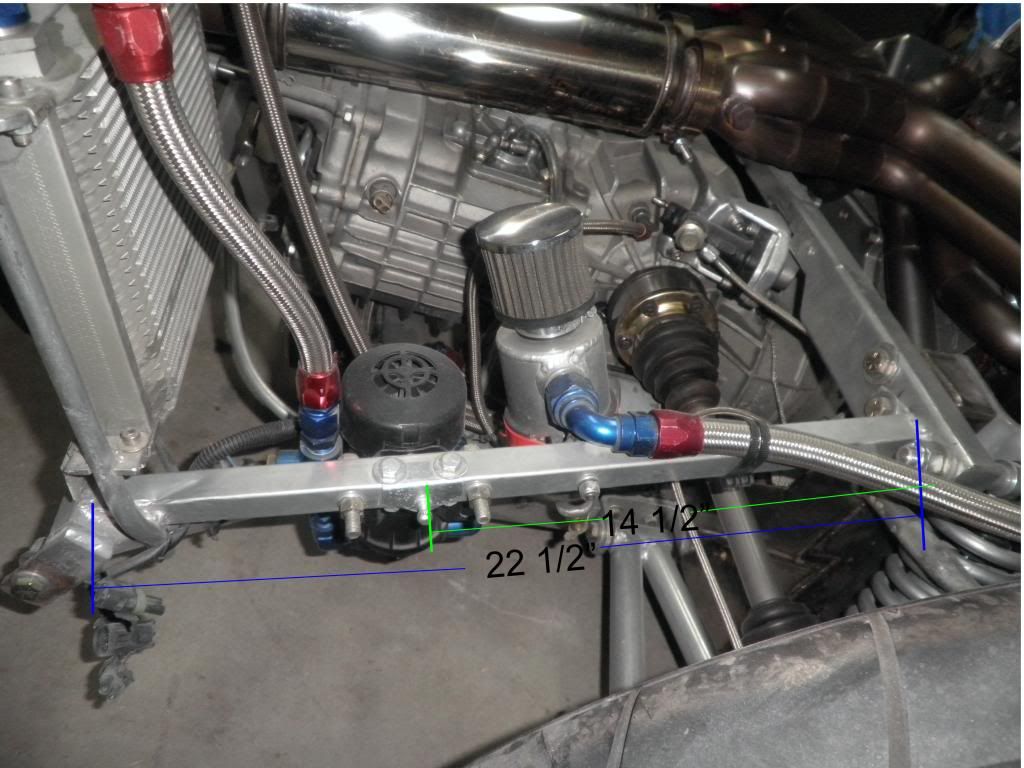

22 1/2"is from the end of the bar at the body mount to the cross motor frame member. The tab on this piece is thinner than the regular tabs. About 2mm

14 1/2" is the mount for the gas shock. The shock is a 40# shock(ebay). Measure the distance from the frame mount to the body mount with the clip open to the position you want it to be open. I chose the point that the clip was just short of being balanced. Measure same when closed. Hold the link mount with a clamp because those should be the lengths you will need when you order them. If they don't match the available lengths on the ebay site then adjust those lengths to match. I had some for the front clip as well @20#, but have since removed them because the front clip is not as rigid as the rear clip and I was having trouble getting it open. Always had to lift from the center of the clip.

This is the body mtg. hardware. It is made out of fiberglass and is pop riveted in place. the mtg. bar is S shaped and is 1/4"(6mm) thick. The gas shock for mine measured 20" extended and 12 compressed and is 40# of lift. That allows you to lift it basically with one hand. It can be found on Ebay. There are lots of lengths on the better sites, so you may have to work with what is close to your measurements. You need to find the point where the clip is almost balanced for its attachment point. Lot of trial and error here.

14" is at the curve of the mount.

3/4" thick is the pointy part. The mount bar section is 1" thick.

1" is all the lips.

I didn't include the positioning of the fiberglass piece. This will be governed by your clip, your vertical supports and the clips final position. Lots of ways to do it. I think that you position the clip to its final closed resting point with an engine lift then loosely attach all the pieces with clamps. Word to the wise, If you use a lift and cotton straps be careful if you go under the wheel wells. This will stress the fiberglass inward. Use a board the length of the width of the wells so that the board takes the inward stress. Mount the 6mm bar to the frame and adjust as needed. Mark all pieces where they seem to fit the best. Remove all and then attach them all together. The mounting bar bolts only go through the fiberglass mounting and not through the vertical supports unless you make this piece solid instead of hollow. This needs to be a tight fit to carry the load. There have been some interesting mounting pieces for the frame in other builds. You may want to search and take a look at those and see if those interest you. This is just basic stuff on mine. I use Nylocs and a bolt to allow the clip to be raised easily.

33 1/4" is the outside measure of the link at the cross motor frame member.

14 is the length from the vertical cross motor frame member mount to the end of the frame.

19 1/4" is the full length of the frame member.

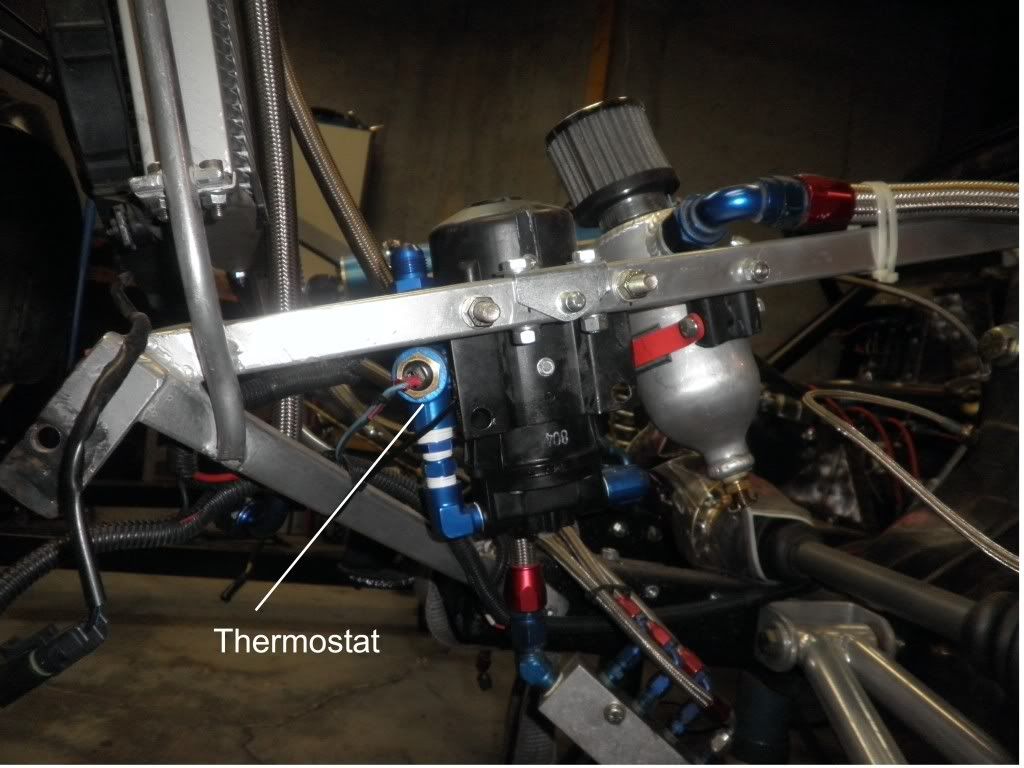

Here are some other shots to help you visualize the set up.