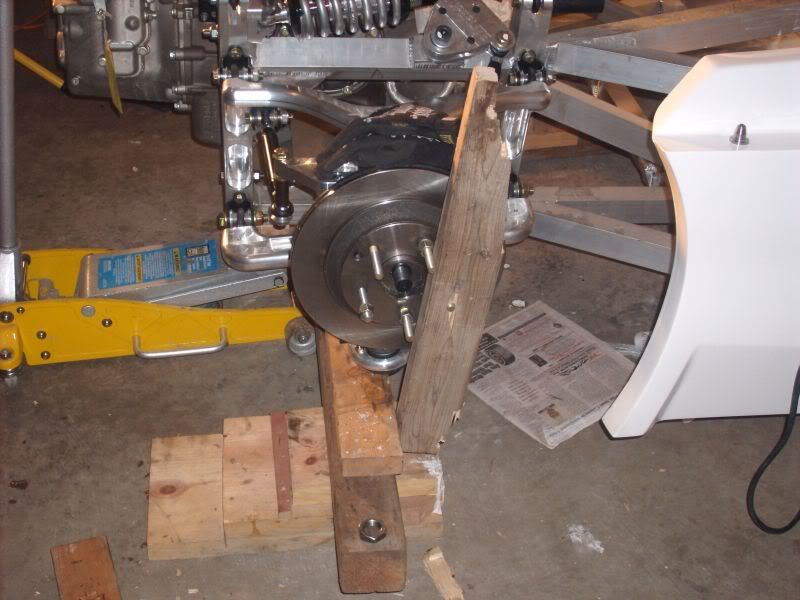

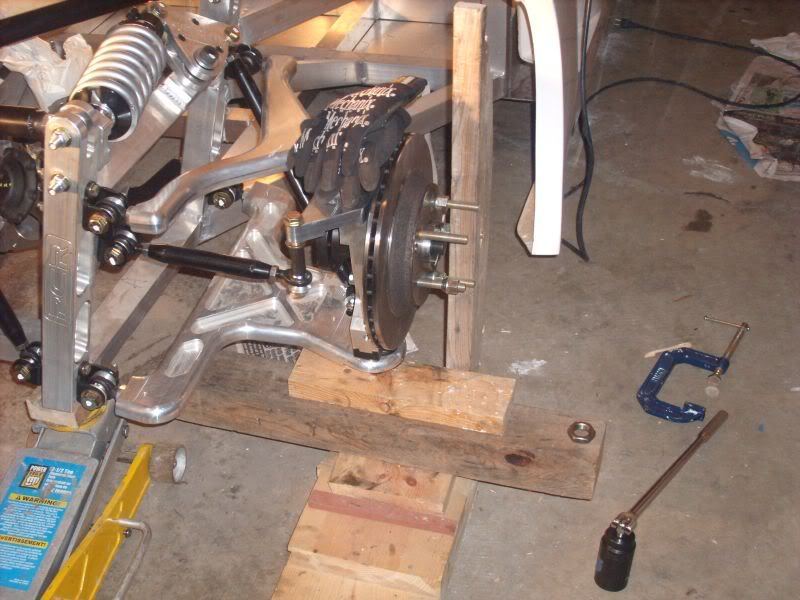

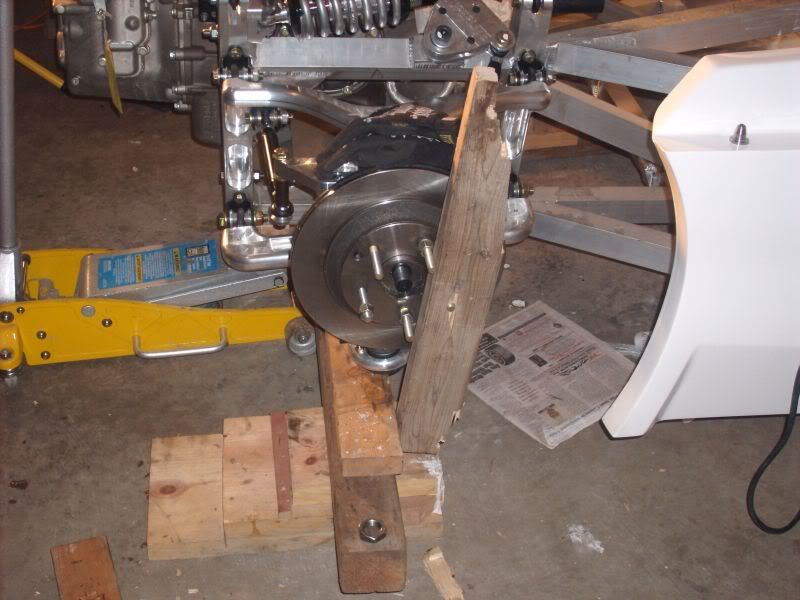

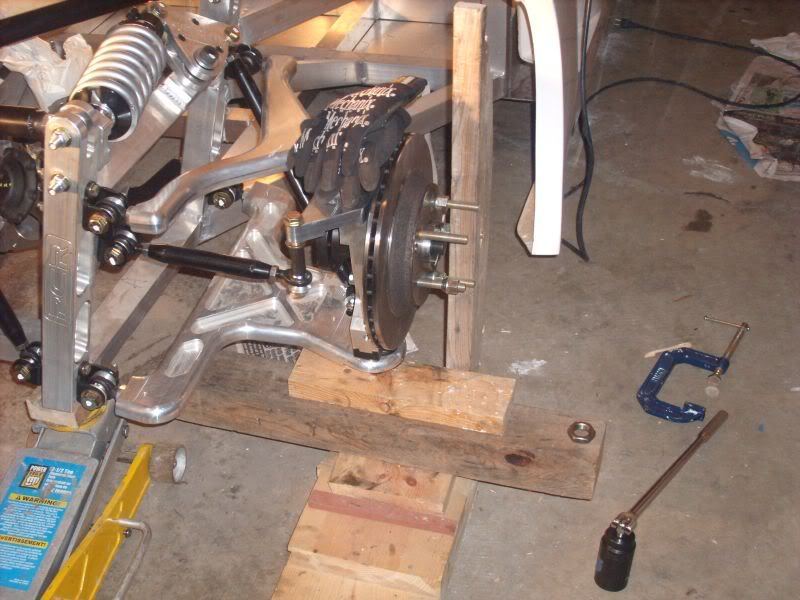

It's amazing how many uses one can find for 2x4s :stunned:

Not only that, but when you're finished torquing your spindle nuts (250ft-lbs, double nutted with blue loctite and a cotter pin; sorry Fran, 120 just seemed a bit too low for my peace of mind for a 1'' bolt....figured since max torque for them is like 1100ft-lbs, 250 was okay for peace of mind), you can use them to make an engine stand as well :drunk:

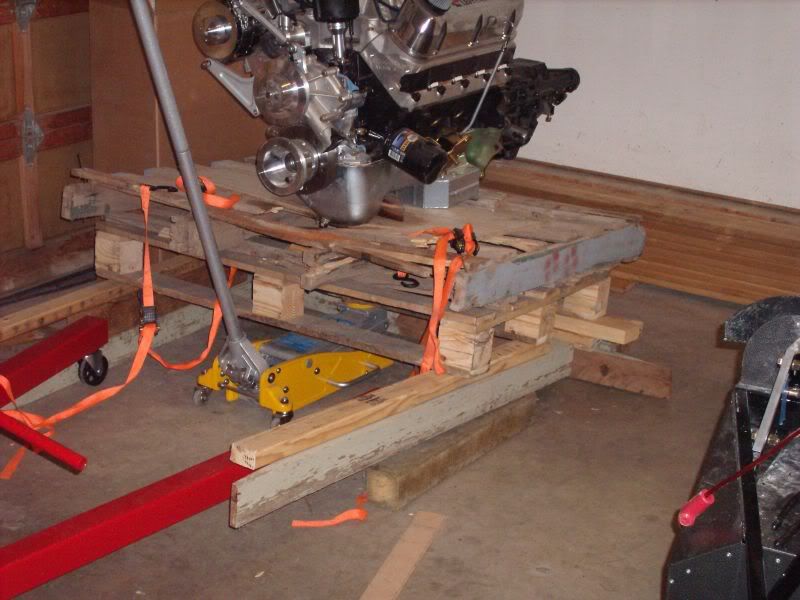

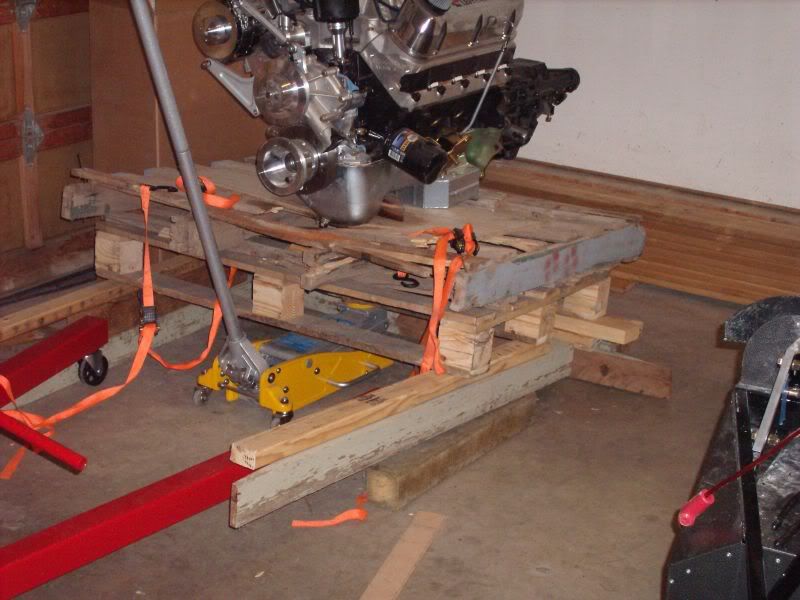

Not only that, but when you're finished torquing your spindle nuts (250ft-lbs, double nutted with blue loctite and a cotter pin; sorry Fran, 120 just seemed a bit too low for my peace of mind for a 1'' bolt....figured since max torque for them is like 1100ft-lbs, 250 was okay for peace of mind), you can use them to make an engine stand as well :drunk: