You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ISIS SLC folk

- Thread starter EFNFAST

- Start date

Hi Alex,

I am probably going with the ISIS as well. There is plenty of room in the foot-wells under the dash or perhaps in the engine compartment behind the drivers side and next to the fuel tank (maybe easier to access unless you can do the "Limbo").

My engine is at the machine shop currently having it's "make-over". I am considering the FAST XFI ECU for engine management and going cable throttle (have a FAST LSXr and 102mm throttle body on order).

Best,

Doc

I am probably going with the ISIS as well. There is plenty of room in the foot-wells under the dash or perhaps in the engine compartment behind the drivers side and next to the fuel tank (maybe easier to access unless you can do the "Limbo").

My engine is at the machine shop currently having it's "make-over". I am considering the FAST XFI ECU for engine management and going cable throttle (have a FAST LSXr and 102mm throttle body on order).

Best,

Doc

I am planning to put the master cell and one or two power cells in front of the chassis where the AC evap and ducting would normally be placed (I am using a different evap, which fits in the cockpit, so I have room there).

The rear one will likely be on a bracket near the right rear of the firewall on the engine side.

The rear one will likely be on a bracket near the right rear of the firewall on the engine side.

^^

I was originally planning on the p/c and m/c in the front of the chassis (as I'm not using the a/c in my car) but Jack showed my some pics of it upfront and it does look like a pretty tight fit there.

Pass. footbox seems like a good place too (from pictures) but I'm always leery of a passenger accidently hitting it (in my cobra I have my I2 power controller in the footbox, at the very top; nobody's ever hit it yet, but still.......)

Hmmmm. Btw, when running wires from the front of the car to the back, is there some sort of tunnel on the side or in the centre where the loom will feed through, or does it just run along the bottom of the chassis?

I was originally planning on the p/c and m/c in the front of the chassis (as I'm not using the a/c in my car) but Jack showed my some pics of it upfront and it does look like a pretty tight fit there.

Pass. footbox seems like a good place too (from pictures) but I'm always leery of a passenger accidently hitting it (in my cobra I have my I2 power controller in the footbox, at the very top; nobody's ever hit it yet, but still.......)

Hmmmm. Btw, when running wires from the front of the car to the back, is there some sort of tunnel on the side or in the centre where the loom will feed through, or does it just run along the bottom of the chassis?

There is a tunnel through the fuel tank that the shiftercables and some wires can be routed through.Hmmmm. Btw, when running wires from the front of the car to the back, is there some sort of tunnel on the side or in the centre where the loom will feed through, or does it just run along the bottom of the chassis?

I've been thinking of going with an ISIS as well but not sure if the cost justifies the means. Since you've installed one Alex, how was it compared to a traditional harness setup? Did you use their original model or the latest setup?

I'm using the original 1+1million relay system in my cobra, and the ISIS in my SLC.

I've already bought the ISIS and it seems to function similarily to the 1+1. There are some differences (e.g., in the 1+1, you individual crimp each wire at the power controller; in the ISIS all the wires are pre-terminated in a large group of weatherpaks that just plug into the unit), but the concept is similar.

Very easy system to wire, and very powerful. I liked it because you don't have to figure out complex wiring, or relays, or even really have to worry about any potential fires (because of the low amount of power travelling through the wires).

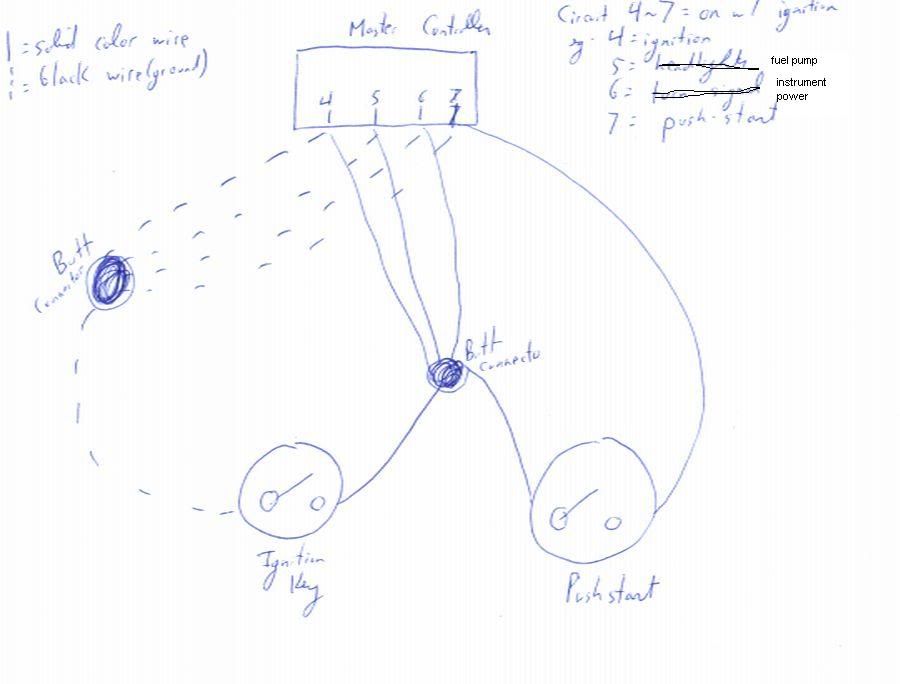

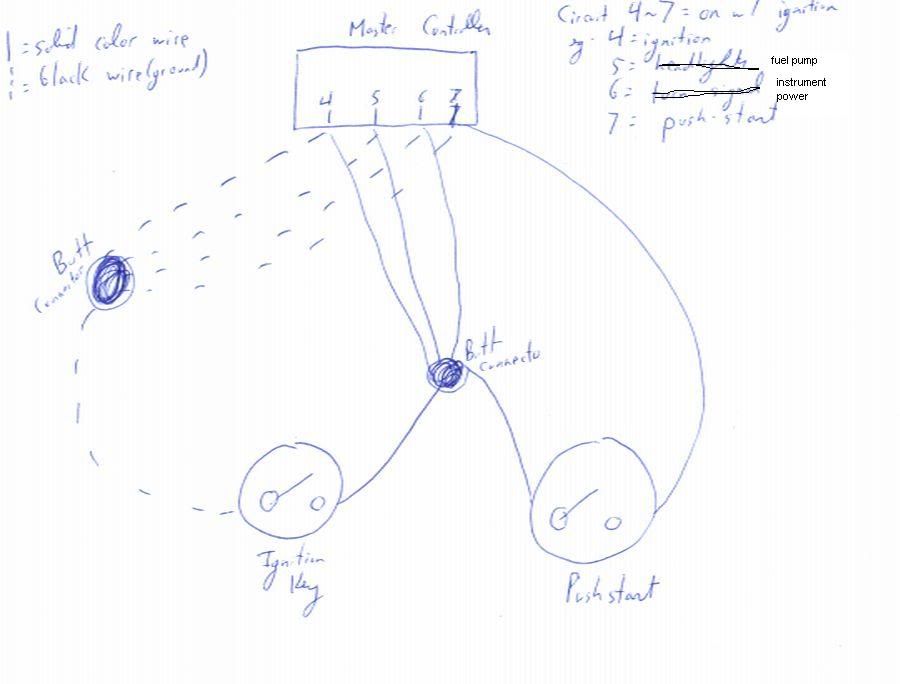

For example, here's a quick wiring diagram of how you'd wire the ignition key and pushstart. In a cobra a lot of people use the s2000 button and standard wiring, and the install gets convoluted to follow.

In this example let's say you've got 4 circuits that are on with ignition (ignition, headlight, turn signal, push-start). You'd join all the ground wires from the master controller together, then 1 ground wire to the ignition key. You'd join all the power wires together (with the push-start first going to/from the push-start button), then 1 main wire ot the ignition key.

When you turn the ignition key, all those circuits are then ready to be used.

Then to wire the starter, for example, you'd take the circuit 7 wire from the power controller and hook it to your starter.

That's it. Easssssssssssy

(this is actually an i2 example, but the isis is very similar; however, i don't want to say it's an isis example until i've actually wired a few circuits myself)

I've already bought the ISIS and it seems to function similarily to the 1+1. There are some differences (e.g., in the 1+1, you individual crimp each wire at the power controller; in the ISIS all the wires are pre-terminated in a large group of weatherpaks that just plug into the unit), but the concept is similar.

Very easy system to wire, and very powerful. I liked it because you don't have to figure out complex wiring, or relays, or even really have to worry about any potential fires (because of the low amount of power travelling through the wires).

For example, here's a quick wiring diagram of how you'd wire the ignition key and pushstart. In a cobra a lot of people use the s2000 button and standard wiring, and the install gets convoluted to follow.

In this example let's say you've got 4 circuits that are on with ignition (ignition, headlight, turn signal, push-start). You'd join all the ground wires from the master controller together, then 1 ground wire to the ignition key. You'd join all the power wires together (with the push-start first going to/from the push-start button), then 1 main wire ot the ignition key.

When you turn the ignition key, all those circuits are then ready to be used.

Then to wire the starter, for example, you'd take the circuit 7 wire from the power controller and hook it to your starter.

That's it. Easssssssssssy

(this is actually an i2 example, but the isis is very similar; however, i don't want to say it's an isis example until i've actually wired a few circuits myself)

Actually, in the above picture I shouldn't have used turn signal and and headlight (I was just trying to think of something in the wiring circuit). It owuld be better to replace them with something more appropriate, such as fuel pump and instrument power.

SO, for example, say circuit 5 was fuel pump (and not headlight). Wiring for the master controller would be the same as above.

Then you'd run a power wire from the power controller to the fuel pump, and ground the fuel pump. That's it, fuel pump now works.

You could also add an on/off switch into the master controller circuit for the fuel pump to be able to turn it on/off. (so the power wire would go from the master controller to one end of the switch, then from the other end of the switch a power wire to join the rest of the on-with-ignition power wires.

SO, for example, say circuit 5 was fuel pump (and not headlight). Wiring for the master controller would be the same as above.

Then you'd run a power wire from the power controller to the fuel pump, and ground the fuel pump. That's it, fuel pump now works.

You could also add an on/off switch into the master controller circuit for the fuel pump to be able to turn it on/off. (so the power wire would go from the master controller to one end of the switch, then from the other end of the switch a power wire to join the rest of the on-with-ignition power wires.

Alex,

Apiece of thinwall aluminum conduit (or PVC) with rubber grommet chafe protection at both ends could be run either side of the chassis above the coolant tubes to use as a wire chase.

I'm not keen on running wires through the fuel tank tunnel, then around the bulkhead and engine to get from front to back.

Apiece of thinwall aluminum conduit (or PVC) with rubber grommet chafe protection at both ends could be run either side of the chassis above the coolant tubes to use as a wire chase.

I'm not keen on running wires through the fuel tank tunnel, then around the bulkhead and engine to get from front to back.

^^

I was originally planning on the p/c and m/c in the front of the chassis (as I'm not using the a/c in my car) but Jack showed my some pics of it upfront and it does look like a pretty tight fit there.

There is plenty of room there for the controllers- the new ones are much smaller than the prior iterations from I2. I'm planning to use the space there to also hold the battery and the lift pump. All of it will be hidden under the FG shroud that normally covers the AC evap.

Pass. footbox seems like a good place too (from pictures) but I'm always leery of a passenger accidently hitting it (in my cobra I have my I2 power controller in the footbox, at the very top; nobody's ever hit it yet, but still.......)

Thought about this, but I didn't want to be upside down in the footwell trying to diagnose (or wire) the units. The boxes should have a cover over them to prevent errant feet from hitting them or dislodging the connectors if you do put them in the foot box.

Hmmmm. Btw, when running wires from the front of the car to the back, is there some sort of tunnel on the side or in the centre where the loom will feed through, or does it just run along the bottom of the chassis?

Jack's suggestion is what I will be doing (running all the wires through a chase down the sides, with the collant, heat and AC piping). I was planning to use sched 40 PVC as it is cheap, lightweight and can be worked easily.

Thought about this, but I didn't want to be upside down in the footwell trying to diagnose (or wire) the units. The boxes should have a cover over them to prevent errant feet from hitting them or dislodging the connectors if you do put them in the foot box..

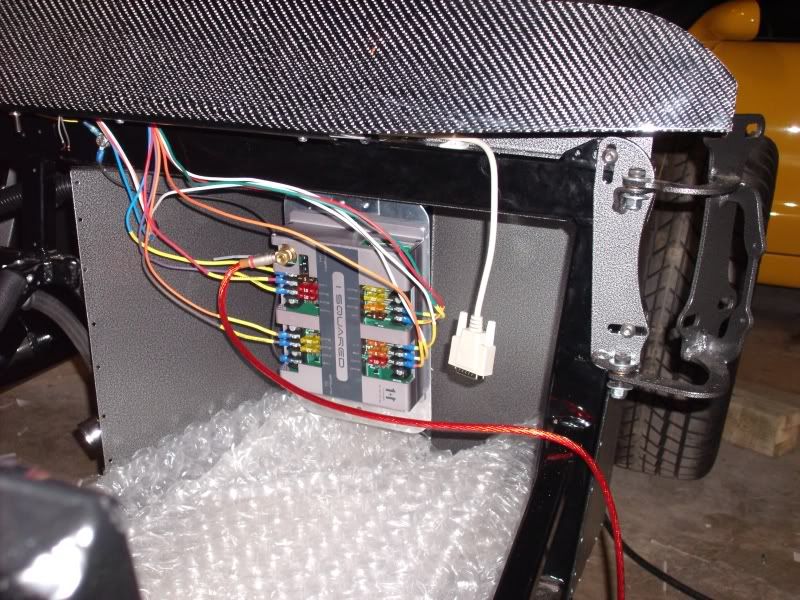

You could always do what I did in my cobra so you arn't wiring it on your back ... drop-down panel

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 9

- Views

- 633

- Replies

- 2

- Views

- 295

- Replies

- 1

- Views

- 368

- Replies

- 8

- Views

- 726