I'm considering building a SLC, and have tentatively decided on using a LS376/480. I have experience building/modifying racing motorcycles, and I've pulled the engine (multiple times) out of a '79 Triumph Spitfire I owned at one time. However, given my utter lack of knowledge, I am somewhat apprehensive when it comes to this project.

I've been gathering as much written information and photos of SLC projects, but the pickings are somewhat slim. I also bought the book "GM LS-Series Engines: The Complete Swap Manual", which has been helpful, but is obviously not SLC specific.

I will be visiting RCR very soon, and I'm hoping that Fran will shed some light on my dilemma.

I'm just wondering where everyone is getting their information regarding engine installation?

From what I've gathered, I will need the following (street car; no track time):

Of course, the engine.

Fuel pump (2 needed?)

Fuel regulator and two fuel filters.

Swirl pot.

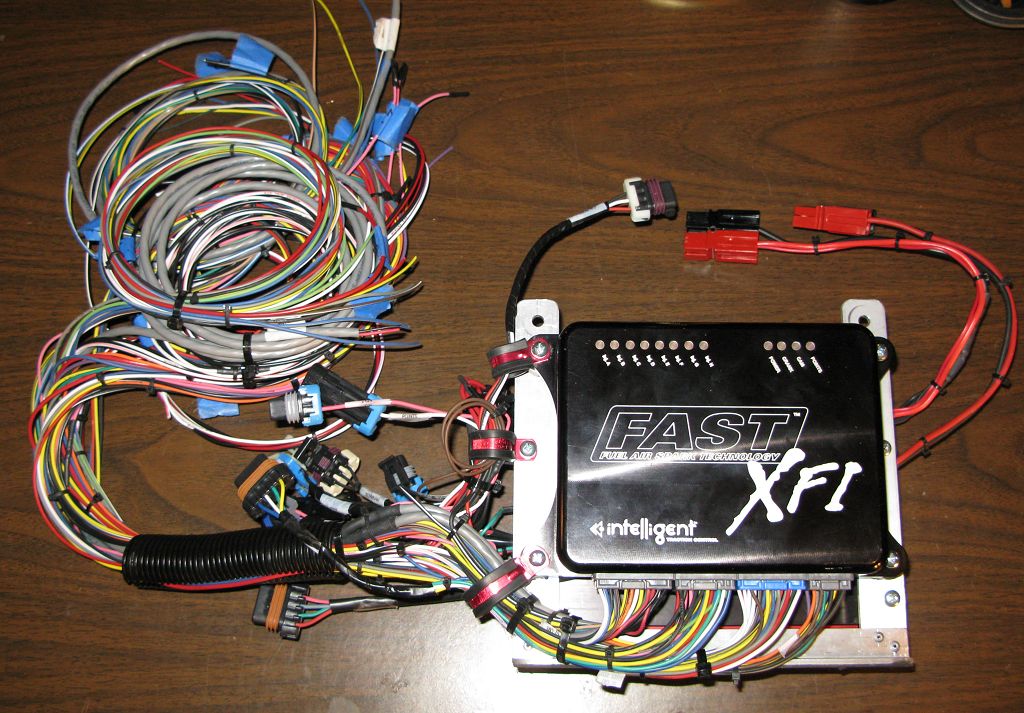

ECU.

Harness.

Starter motor.

Flywheel.

Maybe an Accusump?

Surge tank and primary pump lines.

Alternator and belt.

Silicone lines for coolant line connections.

Modified water pump? Not sure what this entails.

Headers and exhaust.

Any help would be greatly appreciated. :thumbsup:

I've been gathering as much written information and photos of SLC projects, but the pickings are somewhat slim. I also bought the book "GM LS-Series Engines: The Complete Swap Manual", which has been helpful, but is obviously not SLC specific.

I will be visiting RCR very soon, and I'm hoping that Fran will shed some light on my dilemma.

I'm just wondering where everyone is getting their information regarding engine installation?

From what I've gathered, I will need the following (street car; no track time):

Of course, the engine.

Fuel pump (2 needed?)

Fuel regulator and two fuel filters.

Swirl pot.

ECU.

Harness.

Starter motor.

Flywheel.

Maybe an Accusump?

Surge tank and primary pump lines.

Alternator and belt.

Silicone lines for coolant line connections.

Modified water pump? Not sure what this entails.

Headers and exhaust.

Any help would be greatly appreciated. :thumbsup:

Last edited: