Hi All,

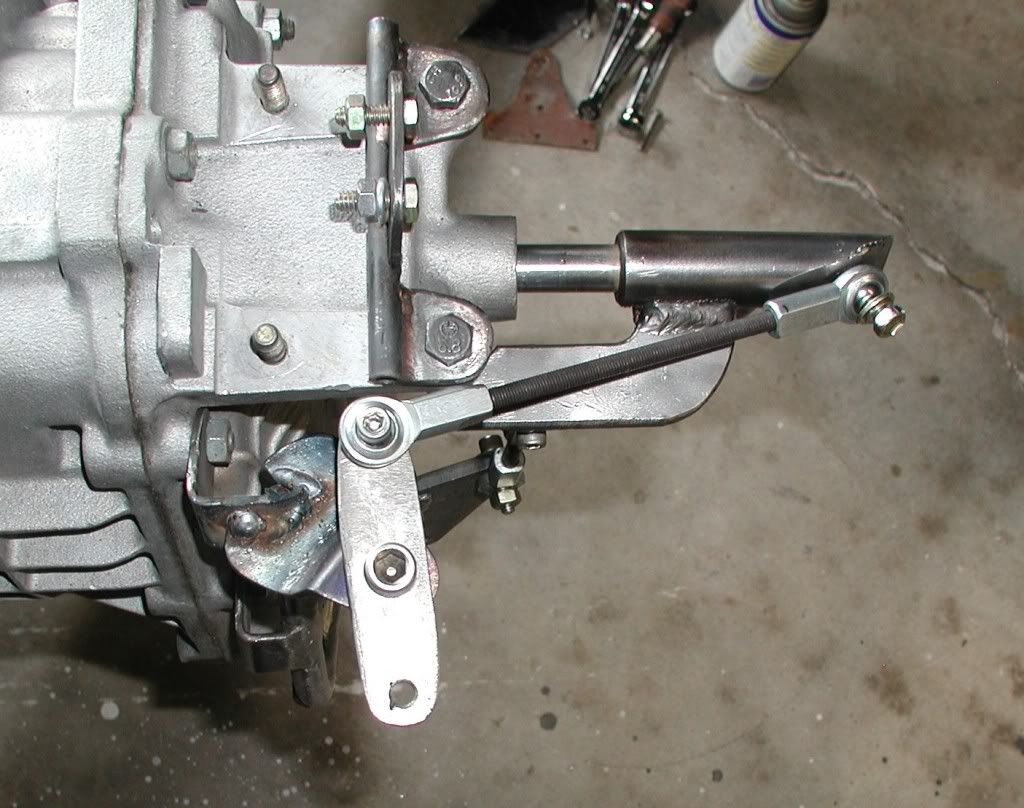

I've come up with this for a shifter design.

Fore - Aft

The fore - aft movement is a direct push pull onto the cable. The outer of the cable goes forward and loops around to the rear. The outer also moves with the left - right movment of the shifter.

Left - right

Left - right goes down through a linkage to the cable mounted on the floor. I would have made this a direct action as well, but there was not enough room to make the turn in between the shifter and the floor.

The cables I intended to be 2" movement 1/4" items from Midwest Control Products - Manufacturers of Ball Joints, Yoke Ends, Spherical Rod ends, Wireforms, and Tube Fabrications

Anyway does the idea look lunatic or not?

I've not shown the support bracketry around the shifter, but you can imagine that.

Are 1/4" cables sufficient in size? All the larger ones I've seen have 3" or more movement which is excessive, the 1/4" versions can have 2" of movement.

I've come up with this for a shifter design.

Fore - Aft

The fore - aft movement is a direct push pull onto the cable. The outer of the cable goes forward and loops around to the rear. The outer also moves with the left - right movment of the shifter.

Left - right

Left - right goes down through a linkage to the cable mounted on the floor. I would have made this a direct action as well, but there was not enough room to make the turn in between the shifter and the floor.

The cables I intended to be 2" movement 1/4" items from Midwest Control Products - Manufacturers of Ball Joints, Yoke Ends, Spherical Rod ends, Wireforms, and Tube Fabrications

Anyway does the idea look lunatic or not?

I've not shown the support bracketry around the shifter, but you can imagine that.

Are 1/4" cables sufficient in size? All the larger ones I've seen have 3" or more movement which is excessive, the 1/4" versions can have 2" of movement.