Hi Frank, Thanks for the 1UZ lesson.

The main reason for this engine has to be that they are dirt cheap.

In holland the where only aviable in the Lexus GS400, so there arent many around here. But because there bullet proof there isn´t any demand for them either.

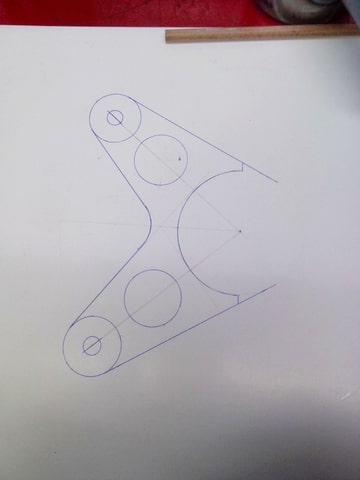

We have heard about the flow problems with the Original heads, our plan is to run the engine with OBX itb, other cams, custom exhaust manifold & a stand alone ecu.

Hoping at 350+ HP.

The main reason for this engine has to be that they are dirt cheap.

In holland the where only aviable in the Lexus GS400, so there arent many around here. But because there bullet proof there isn´t any demand for them either.

We have heard about the flow problems with the Original heads, our plan is to run the engine with OBX itb, other cams, custom exhaust manifold & a stand alone ecu.

Hoping at 350+ HP.