Mike,

Few things :

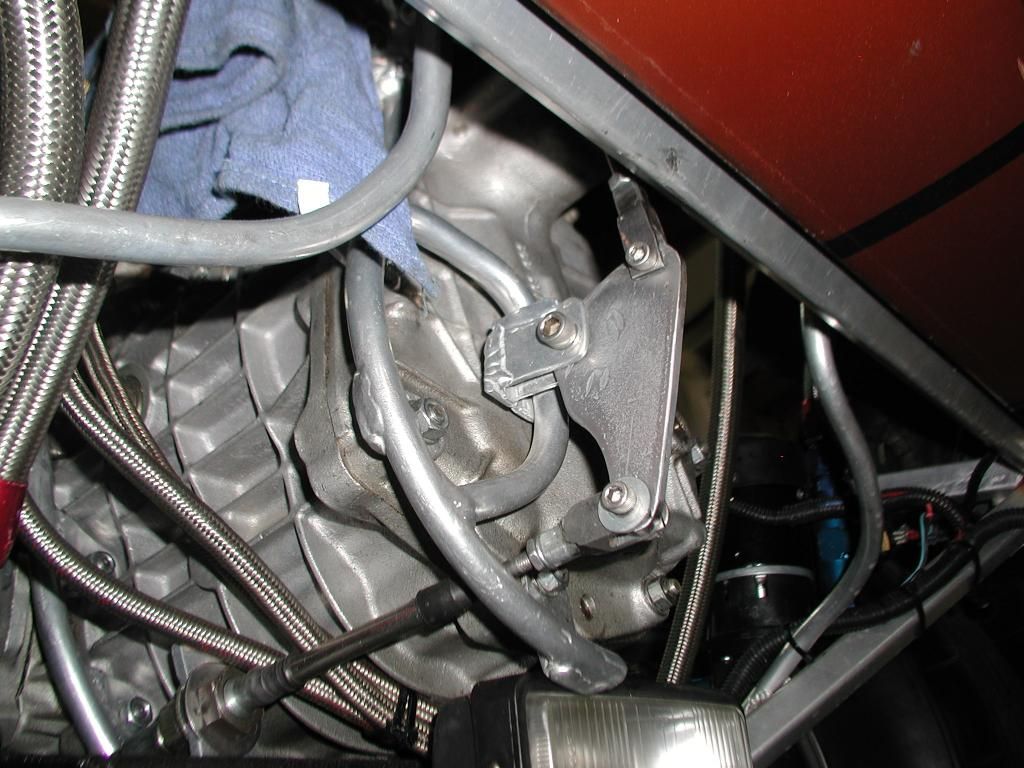

1st : Where did you get your gearbox. Your rear cover is the one used in the very first versions of the UN1 gearboxes and no versions of the UN1-13 went with this rear cover. There is no oiling of the 5th gear assembly, so for sure you will break. I strongly recommend you to replace your rear cover to the standard one.

2nd : Your setting, with the UN1, will inevitably drive to bad shifting. Unfortunately, there is some OEM clearances between the finger and the arm helping the finger to move laterally, so because you act on 2 different parts wich have some clearances, it is a very bad seeting. The only way to restore something acceptable is to have actions only on the main arm, the one which hold the finger. You can have a look at a lotus setting and replicate it....even if it is still not perfect but far better than this 2 ways.

If you want to keep your existing setting, I would recommend to shorten the arms, with this length + OEM clearances, you are making exponential mistaken dispalcements....

3rd : Check the tips of your links (inside the gearbox, just removing the rear cover, most of the time, they are worn. The standard (OEM) is to have them perfectly squared, no V shapes

Best

Stephane