You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Use a drop gear to lower/raise gearbox?

- Thread starter croc

- Start date

If you use two spur gears ala Quick Change your rotations will change from there onward,

other way would be internal gear similar to cresent type pump gears out of auto trans to maintain correct rotation.

My thoughts..M.I.S.S. make it simple ******

Some of the brabham F1/indy trans by Weismann split the final drive reduction by a combo of spiral bevel on the input ( small size-less torque requirement @ that point & to convert from the engine crankshaft thru 90°) to allow for spur gears for all trans ratios & further reduction to final drive/output shafts ( these were accessable by pulling side cover to make rapid ratio changes possible ) and also allowed some design freedom to get axle/output shaft heights at correct levels.

other way would be internal gear similar to cresent type pump gears out of auto trans to maintain correct rotation.

My thoughts..M.I.S.S. make it simple ******

Some of the brabham F1/indy trans by Weismann split the final drive reduction by a combo of spiral bevel on the input ( small size-less torque requirement @ that point & to convert from the engine crankshaft thru 90°) to allow for spur gears for all trans ratios & further reduction to final drive/output shafts ( these were accessable by pulling side cover to make rapid ratio changes possible ) and also allowed some design freedom to get axle/output shaft heights at correct levels.

Well, the G50 crown wheel is on the "wrong" side anyway ('box in upright position) so that would be very advantageous for me.If you use two spur gears ala Quick Change your rotations will change from there onward,.

Not for me but has anybody done that to a manual gearbox? Is there a thread or a link about it?other way would be internal gear similar to cresent type pump gears out of auto trans to maintain correct rotation..

You mean transverse gearbox?My thoughts..M.I.S.S. make it simple ******

Some of the brabham F1/indy trans by Weismann split the final drive reduction by a combo of spiral bevel on the input ( small size-less torque requirement @ that point & to convert from the engine crankshaft thru 90°) to allow for spur gears for all trans ratios & further reduction to final drive/output shafts ( these were accessable by pulling side cover to make rapid ratio changes possible ) and also allowed some design freedom to get axle/output shaft heights at correct levels.

Yes, but with inline motor, input shaft for trans is pinion of a lighter ring/pinion which converts it to traverse shafts from thereon...Well, the G50 crown wheel is on the "wrong" side anyway ('box in upright position) so that would be very advantageous for me.

Not for long, cos then you will be driving on the coast side & coasting on the drive side of the CWP- it probably wont like that long term

Not for me but has anybody done that to a manual gearbox? Is there a thread or a link about it?

Not that I can think of offhand, just used it as a possibility

You mean transverse gearbox?

Well, the G50 crown wheel is on the "wrong" side anyway ('box in upright position) so that would be very advantageous for me.

What the heck are you planning? An extreme off roader?

You are contemplating a G50 in that orientation? You must want the motor still higher, because getting it lower is easy. That is, unless you are running massive diameter rear wheels and need to drop it more than what you would achieve by flipping the trans. OK, obviously a wierdo application!

Have you thought of drop gears on the output shafts a la old VW Kombi? This will lift/lower the whole motor/trans assembly. You could have them either inboard or outboard...

And if you need the direction of rotation opposite to what that achieves, use three drop gears not two.

Last edited:

Damn! You are right. I've just double checked the pictures of the Cooper Climax gearboxes - the Mk2, which was fitted with a drop gear, used a custom CWP (straight bevel instead of spiral bevel) so that's why. The Mk1 did not have a drop gear and the CWP was standard (spiral bevel).Not for long, cos then you will be driving on the coast side & coasting on the drive side of the CWP- it probably wont like that long term

Last edited:

^ Yes, that's what I was talking about.

BTW why did Cooper decide to make a straight bevel CWP rather than a spiral bevel but of oppposite hand?

Purely a guess..$$$$$$$, race car constructors of that era like cooper, chapman etc were more like privateers and not as sponsor endowed as the teams are now--- in one of the books about chapman it tells how he actually ran a mismatched ring gear from one ratio against the pinion from another ratio to get the desired ratio for one of his early pre-7 series cars.... hope I am not putting ideas in your head

^ So, if it was a G50 gearbox, would an opposite handed (or mirror imaged) hypoid bevel CWP work?

No, not really, I modded your dwg to give it some hypoid & polaced -red- tooth patterns to give you an idea why the tooth angle & shaft loads go all to pot!!!

Last edited:

Sorry for late response. Anyway, if I flip the trans, the output shafts would be about 5" too high. Actually I don't need drop gears either - just trying to figure out how to use the G50 that's all. In upright position my output shafts are only about 1.5" too low, so if I use, say, a 2" drop gear, the axles will be flat.What the heck are you planning? An extreme off roader?

You are contemplating a G50 in that orientation? You must want the motor still higher, because getting it lower is easy. That is, unless you are running massive diameter rear wheels and need to drop it more than what you would achieve by flipping the trans. OK, obviously a wierdo application!

I see what you mean. Anyway, after some thinking I think there are basically 4 hypoid orientations. I have modded the dwgs as well but unfortunately don't have the priviledge to upload. :shrug:No, not really, I modded your dwg to give it some hypoid & polaced -red- tooth patterns to give you an idea why the tooth angle & shaft loads go all to pot!!!

I'll try to figure out how to upload them tomorrow.

It's OK, I'm not going to bother to upload the dwgs. I now realise that positive hypoid is the only way because negative hypoid (not to be confused with opposite handed) will not work no matter what.

I thought the Audi/Boxster/Cayman gearboxes were negative hypoid but they're not - a bit like an upside down G50 but with the input shaft above it not below.

I thought the Audi/Boxster/Cayman gearboxes were negative hypoid but they're not - a bit like an upside down G50 but with the input shaft above it not below.

Last edited:

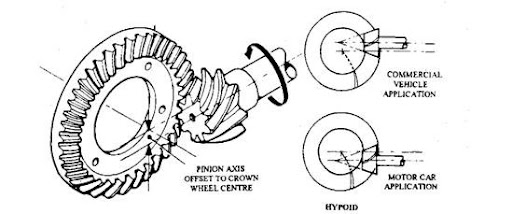

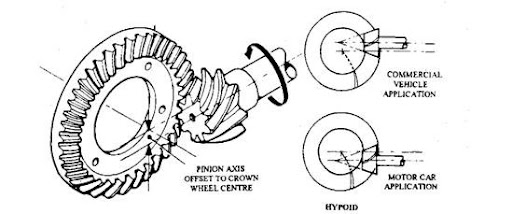

Just look what I've just discovered !!!!!!!!! :

See the two diagrams on the right? The top one is what I called "Negative" hypoid, so it DOES work afterall. Notice the tooth angle, which is more favourable (stronger!), compared to the one in the lower diagram? Wow! But apparently only suitable for commercial vehicles. Why's that? Noisy?

See the two diagrams on the right? The top one is what I called "Negative" hypoid, so it DOES work afterall. Notice the tooth angle, which is more favourable (stronger!), compared to the one in the lower diagram? Wow! But apparently only suitable for commercial vehicles. Why's that? Noisy?

Ive rotated the dwg you provided to help explain.. note the red line which for all intents & purposes would be the c/l of the pinion superimposed on the Crownwheel with CW tooth pattern, to work in that position the Pinion will now have a virtually straight bevel tooth with a slight curve in it.

Why would they do it, strength- groundclearance- noise not as much of a factor... now all you need is to find one that works for your application..

Why would they do it, strength- groundclearance- noise not as much of a factor... now all you need is to find one that works for your application..

Last edited:

Yes, clearer than mud. Thanks for the clarification.

So, a disadvantage is the possible noise increase. Do you think it will be noisier than a non-hypoid spiral bevel?

Am I right thinking that the advantages of a commercial vehicle hypoid CWP pair (given the same size) are as follows? :-

So, a disadvantage is the possible noise increase. Do you think it will be noisier than a non-hypoid spiral bevel?

Am I right thinking that the advantages of a commercial vehicle hypoid CWP pair (given the same size) are as follows? :-

- Has higher torque strength than motor car hypoid bevel

- Does not slip, thus no power consumption

- Runs cooler than motor car hypoid bevel

- Does not require hypoid oil

- Runs cooler than non-hyoid spiral bevel

- Can sustain higher rpm’s (10,000+ rpm)

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 74

- Views

- 6K

- Replies

- 13

- Views

- 3K