Have a carb'd 408w.

I was studying my dyno sheet from last year and was wondering about the a/f (can't scan it unforunately, I will describe)

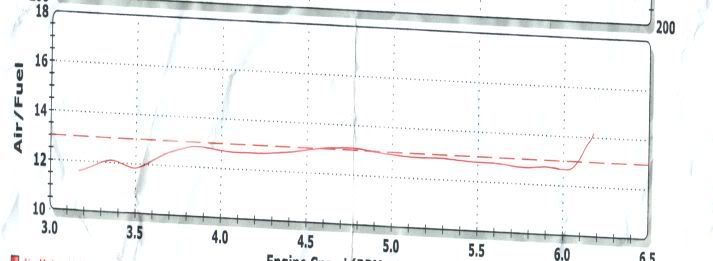

from 3000 to 3500, a/f is around 11.9

from 3600 to 6100 a/f is around 13

from 6100 to 6400 a/f is around 14.5

Does this sound like a good a/f for a carb'd 408w? By good, I mean decent power and safe. Not too rich, not too lean. I think it is, but wanted to get others ideas.

edit: Also, does the fact that from 6100 to 6400 the a/f really leans out means anything? (I have my rev limiter set to 6400, could theoretically rev to 6600 if I wanted but I dont')

I was studying my dyno sheet from last year and was wondering about the a/f (can't scan it unforunately, I will describe)

from 3000 to 3500, a/f is around 11.9

from 3600 to 6100 a/f is around 13

from 6100 to 6400 a/f is around 14.5

Does this sound like a good a/f for a carb'd 408w? By good, I mean decent power and safe. Not too rich, not too lean. I think it is, but wanted to get others ideas.

edit: Also, does the fact that from 6100 to 6400 the a/f really leans out means anything? (I have my rev limiter set to 6400, could theoretically rev to 6600 if I wanted but I dont')