HAllo ,

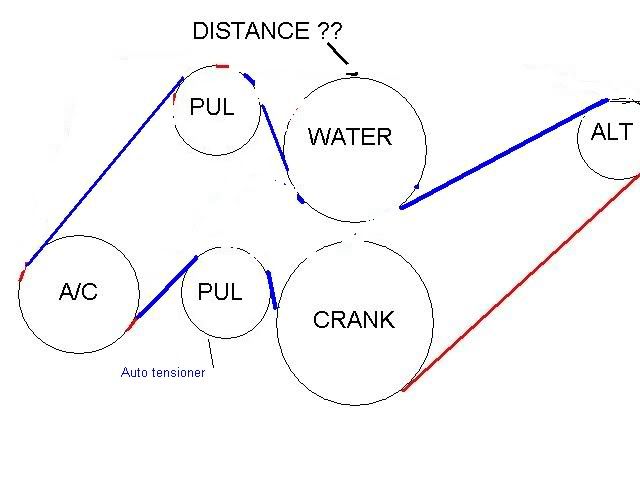

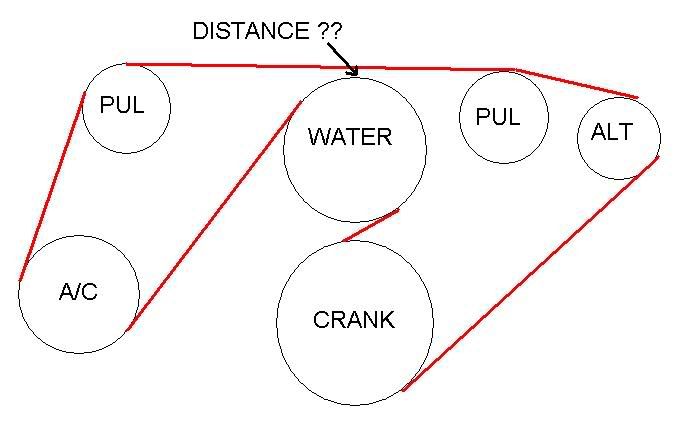

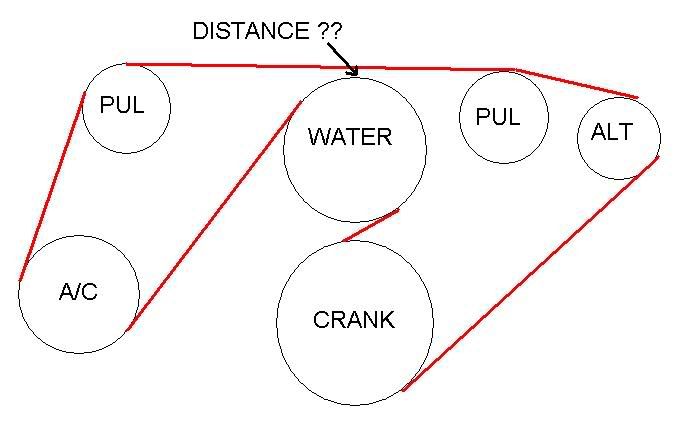

this is a sketch of my serpentine setup.

it is planned for a standard 6 rib serpentine belt.

Now my questions:

Do i need a automatic tensioning pulley ( which i would have difficulties to find a place for ) ?? I have on from Ford and have no glue how it works, it is somehow fixed ( at least i can not move it with my arms and hands force to see in which direction it works).

Would it be possible to run without and have the tension controlled by the adjustability of the alternator ?

If so how to test the correct tension ??

if you look on the sketch you see the belt running back to the alternator along the waterpump pulley. On the water pump pulley itself the backside of the belt is running in the opposite direction versus the belt running along. So one want to avoid that both sides are getting in contact. What is a save distance to do so at correct tension of the belt ??

Thanks for your help

TOM

this is a sketch of my serpentine setup.

it is planned for a standard 6 rib serpentine belt.

Now my questions:

Do i need a automatic tensioning pulley ( which i would have difficulties to find a place for ) ?? I have on from Ford and have no glue how it works, it is somehow fixed ( at least i can not move it with my arms and hands force to see in which direction it works).

Would it be possible to run without and have the tension controlled by the adjustability of the alternator ?

If so how to test the correct tension ??

if you look on the sketch you see the belt running back to the alternator along the waterpump pulley. On the water pump pulley itself the backside of the belt is running in the opposite direction versus the belt running along. So one want to avoid that both sides are getting in contact. What is a save distance to do so at correct tension of the belt ??

Thanks for your help

TOM