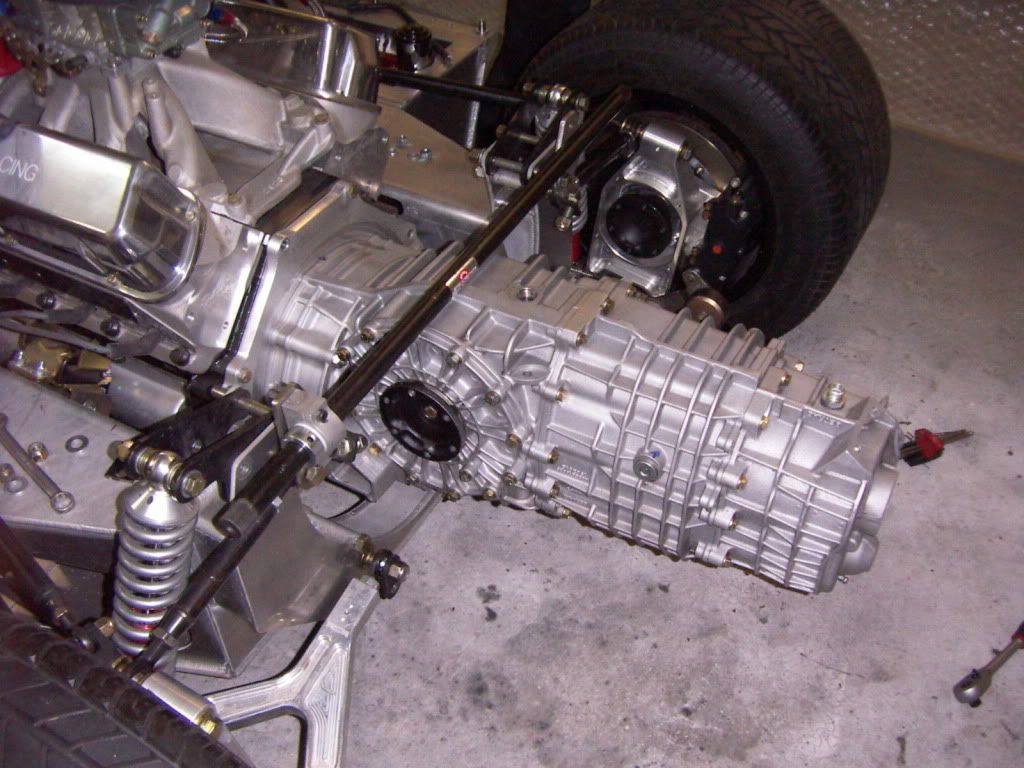

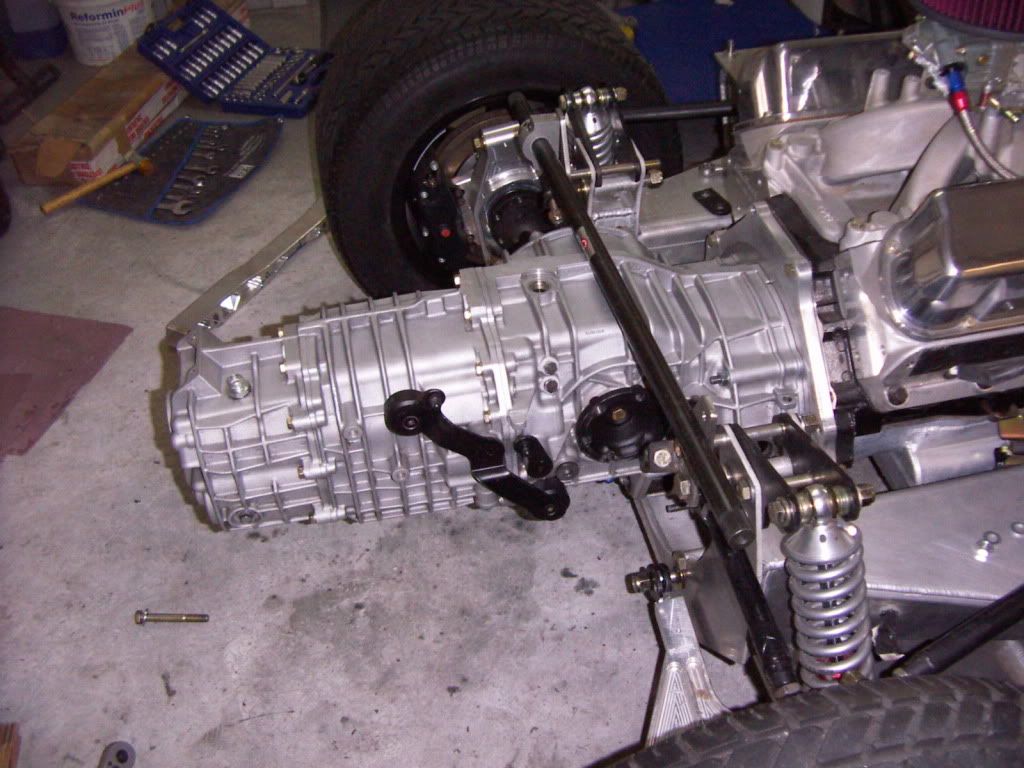

Iv'e been tossing the Idea of trading up the transaxle. With a possible sale on my G50/01 and my hands on a 996 GT3 trans things are looking good.

Just a minor problem of paying for the 996.

So while Im saving my pennies Iv'e started on the drivers cockpit.

Its trickier than I imagined to get the seat, peddles, the steering colum and gauges all in the right place. I started with the seat then fabricated the peddles then I must have made 10 different brackets for the cloum then shifted the seat. Made cardboard gauges to see how the layout works, or not as the case maybe.:furious: Then shifted the peddles and the seat

Now I can see out the windscreen. I'm just glad theres a fridge in the garage :shy:

Just a minor problem of paying for the 996.

So while Im saving my pennies Iv'e started on the drivers cockpit.

Its trickier than I imagined to get the seat, peddles, the steering colum and gauges all in the right place. I started with the seat then fabricated the peddles then I must have made 10 different brackets for the cloum then shifted the seat. Made cardboard gauges to see how the layout works, or not as the case maybe.:furious: Then shifted the peddles and the seat

Now I can see out the windscreen. I'm just glad theres a fridge in the garage :shy: