I've only got a couple of additions to what's been said;

1) Spend a few extra dollars and buy the highest quality AN Fittings. The only way that I will ever put a Russell or Earls fitting in one of my cars is if it is not available from Aeroquip. Yes - I will buy Aeroquip whenever possible as I feel they are of the highest quality. Same goes for the hoses.

2) Cutting of hose to length - I tape (duct tape) over the hose with two full wraps (tight) and then use a Cut-off wheel. I wash the hose out thoroughly after assembly to remove all traces of particles. Others use sharp chisels (I never really mastered it - but it does work). There are special cutters (Shears) that are made for this task - but I've never bought one.

3) Never use teflon thread tape or sealing compound on an AN fitting unless it's the end that is threaded as a PIPE fitting.

4) Always lubricate the hose using hose assembly oil or a bit of 30w motor oil (make certain this is washed out after complete assembly)

5) Always put just a drop or two of oil on the threads of a hose fitting so as to eliminate the potential of galling the threads when assembling.

6) Understand that AN fittings and braided hose do not have an infinite life span. It varies by conditions it's being used under and the contents being carried. For fuel lines (hoses) carrying gasoline - the rule of thumb is generally 5 years for a quality hose. I've seen some that start to weep after little more than a few months. It all goes back to the quality of the hoses and components.

All this said - I've made hundreds of hoses in this manner and they've all performed as expected with little to no drama involved.

Recently I happened upon a fellow using a new tool for assembling hose ends that intrigued me so much I tried it. Now I have a full set and I'll tell you right now, my hose assembly time is cut fully in half.

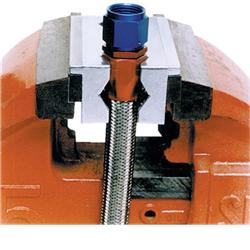

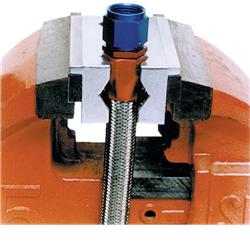

I used to always use a vice with aluminum jaws or minimally a vice with cardboard taped to the jaws to assemble the hose ends - until the discovery of the Koul Tool;

KOUL tools, LLC - Lake Havasu City, AZ

I still use the aluminum jaws for holding the fitting while turning the hose end on;