Jac - I would think vibration would still be worse in the flat plane mode.I remember my friends Chevy Monza which ,early on, came through with a 180 crank.The engine(V6) seemed to have more torque than the comparable motor with the conventional crank - it felt quicker but you definitely knew when the engine was pulling as it was noticeably rougher and for some reason,louder.Also,I had thought that the Sprint car boys went the flat plane route in their Chevy's to get more torque off the corner and to allow more time between power pulses so the tires could get more bite in the dirt.As for less rotating mass,you could get the same benefit for a lot less dough by using a smaller diameter and lighter flywheel and smaller multi disc clutch. Your opinion? A.J.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flat plane crank in a SBF?

- Thread starter Cliffbeer2

- Start date

AJ, the flat plane vibration factor increases in magnitude with stroke & component mass, thats why the likes of ferrari with relatively small cylinder capacities & weights are more suitable for the principle.

The Monza with a V6 would have been a 90° block with a common pin crank & therefore odd firing intervals by the sound of it . Buick went thru variations of this and split journals on their V6 as well as Chevy. Ford also with its Nascar version of the 3.8 V6

Flat plane V8 still fires @ 90° intervals unless you convert it to ' big bang' configuration with two cyls firing every 180°. Was a thread on that earlier this year with Bikes doing this for traction reasons also.

Yes , you can do it for less with just the lighter clutch/flywheel assy----UNTIL I come along and combine it with a flatplane crank & live with the vibration.

The Monza with a V6 would have been a 90° block with a common pin crank & therefore odd firing intervals by the sound of it . Buick went thru variations of this and split journals on their V6 as well as Chevy. Ford also with its Nascar version of the 3.8 V6

Flat plane V8 still fires @ 90° intervals unless you convert it to ' big bang' configuration with two cyls firing every 180°. Was a thread on that earlier this year with Bikes doing this for traction reasons also.

Yes , you can do it for less with just the lighter clutch/flywheel assy----UNTIL I come along and combine it with a flatplane crank & live with the vibration.

:laugh::laugh::laugh: LOL!!! :laugh::laugh::laugh:

Un-Bloody-Believable....

Just when I thought I'd seen it all - along comes a gizmo that'll turn a Fiat 500 into a Barracuda... yeah right..:laugh:

Mind you, I can see this being VERY popular at numerous Halfords Car Park weekend meetings across the country where just about every Citroen Saxo must have 500BHP judging by the size and sound of their tailpipes.:thumbsup:

LOVE IT!!!

Last edited:

AJ, the flat plane vibration factor increases in magnitude with stroke & component mass, thats why the likes of ferrari with relatively small cylinder capacities & weights are more suitable for the principle.

Exactly. I also would like to add that rod to stroke ratio also has a “strong” influence on the 2nd order harmonic as well.

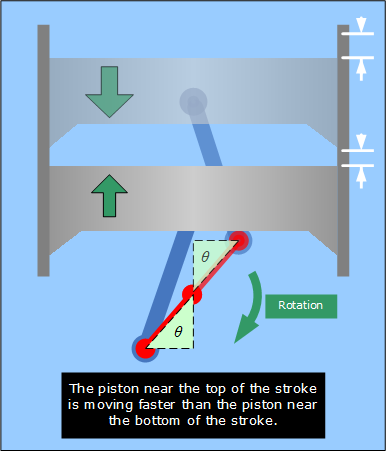

Recently had the fine opportunity to talk with Mr David Vizard on the phone for just over an hour and half on the subject of a domestic V-8 single plane crankshaft, (the thread I linked earlier). One of the topics was the relationship of rod to stroke ratio to the 2nd order vibration. The 2nd order vibration is inherent design bug/feature for flat plane V-8 and inline 4 cylinder engines alike, (illustration below). At any given instant, the velocities of the pistons traveling upward does not equal the velocities of the cylinders traveling downward. The net velocity of all eight cylinders is therefore not equal to zero, which causes vibrations, felt as buzziness to the occupants of the vehicle.

Just as Jac Mac already stated, the 2nd order harmonic is directly related to the amount of stroke, the mass of the reciprocating parts, (pistons and the upper half of the con rods), “and” the rod to stroke ratio. At one end of the spectrum, if you have an infinite rod length, the 2nd order harmonic does not exist, regardless of the piston mass and crank stroke. So the longer the rod to stroke ratio, the less the 2nd order harmonic. In my phone conversation with David Vizard, he felt that rod to stroke ratios of 2.2:1 or greater, the 2nd order harmonic reduction will be incremental and depending on budget for such a project vs the driver/occupants tolerance level for engine “buzziness”, the point of diminishing returns is being approached. i.e., to go from 1.5:1 to 1.7:1 would have significant reduction in 2nd order harmonics and most likely worth the effort, though to go from 2.5:1 to 2.7:1 would have much less an impact and the 2nd order harmonic is already much less at the longer rod to stroke ratio.

Last edited:

Jac - I would think vibration would still be worse in the flat plane mode.I remember my friends Chevy Monza which ,early on, came through with a 180 crank.The engine(V6) seemed to have more torque than the comparable motor with the conventional crank - it felt quicker but you definitely knew when the engine was pulling as it was noticeably rougher and for some reason,louder.Also,I had thought that the Sprint car boys went the flat plane route in their Chevy's to get more torque off the corner and to allow more time between power pulses so the tires could get more bite in the dirt.As for less rotating mass,you could get the same benefit for a lot less dough by using a smaller diameter and lighter flywheel and smaller multi disc clutch. Your opinion? A.J.

I’m more or less parroting what Jac Mac stated. I think you might be confusing common pin crank for a flat plane. The v-6 by design realistically can’t be had in a flat plane config, though I guess it could if one really really wanted that. A 90 degree V-6 block with common pin would be odd fire and would have vibrations induced from the odd firing times.

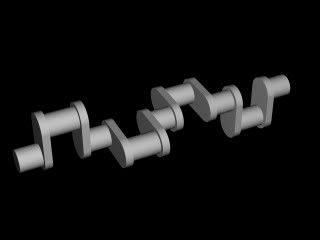

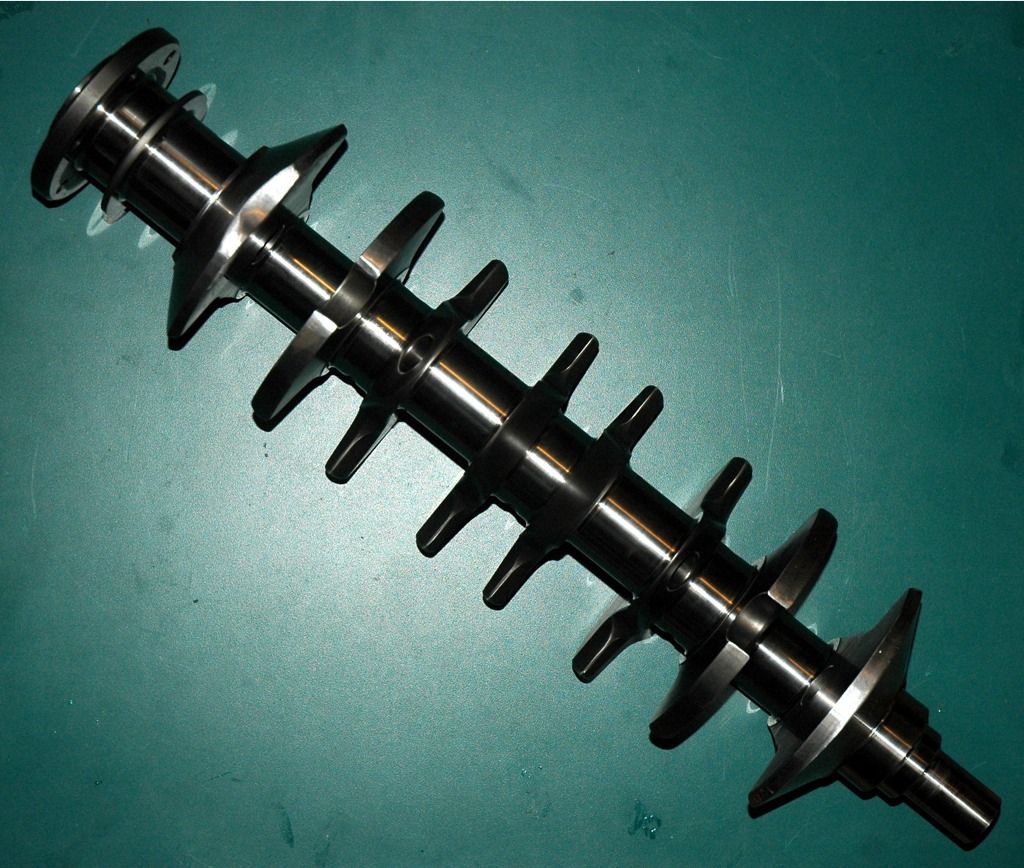

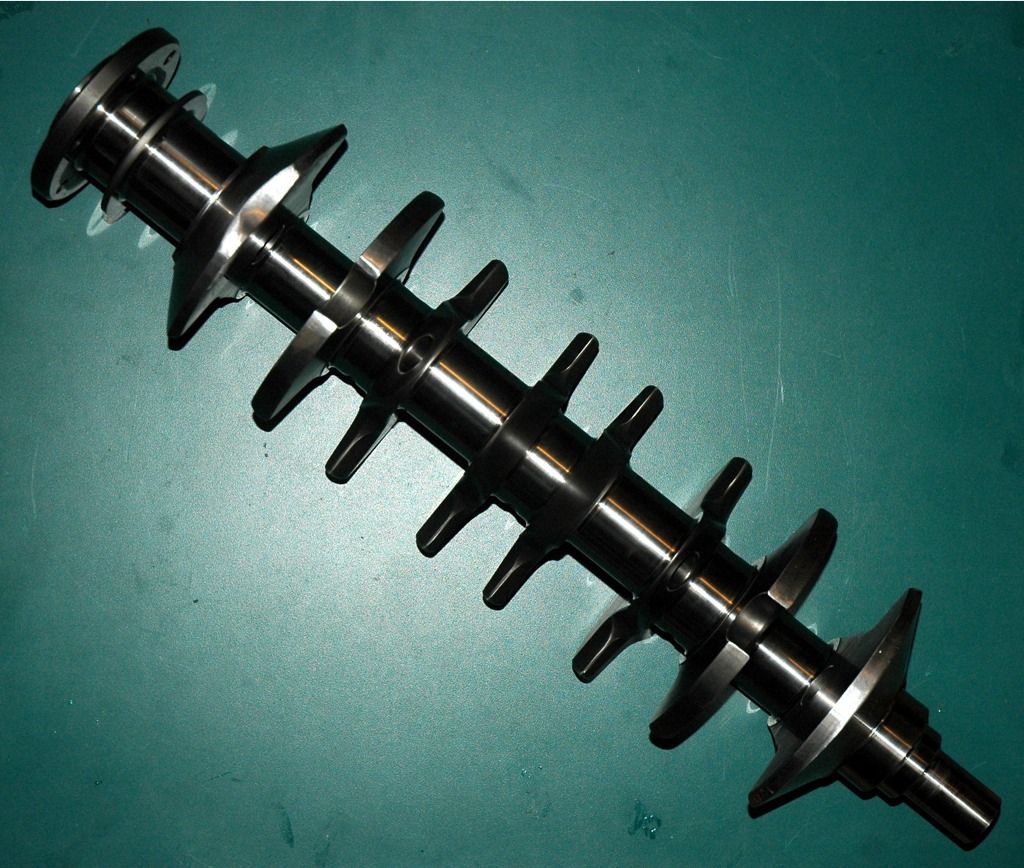

Below are a couple illustrations for the common crank configuration for single and dual plane V-8 cranks, (inline 4’s and flat 4’s are also flat plane).

Left is "Single Plane", right is "Dual Plane"

Note the crank pin configuration. When looking down the front of the crank, there is a crank pin every 90 degrees, on two planes, hence the name Dual plane, or 90 degree crank.

Here is how the dual plane/90 degree crank looks;

DUAL PLANE

Here is Dual Plane LS1 crank and CAD rendering of a Dual Plane SBC 350 crank;

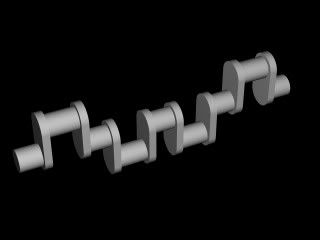

Here is how the single plane/180 degree crank looks;

SINGLE PLANE

And here is a Ferrari 355 Single Plane V-8 crank;

…and here is a SBC Single Plane Crankshaft (two piece rear main seal)!

As for power/torque differences between the two crankshaft designs for a given displacement and comparable builds? Here is a partial list of the pros and cons for single plane and dual pane V-8 crankshafts, as I understand them.

Single Plane;

Pros;

1) Exhaust pipe length tuning due to the even pulses per bank of cylinders, (on a 400 HP engine could be worth 5-10 HP).

2) Exhaust note, (this is more of a personal taste thing)

3) Lighter weight crank due to less mass needed in the counterweights for a given stroke. Faster revs, though not as smooth.

4) It’s different!

Cons;

1) 2nd order harmonics. Those harmonics are exaggerated with displacement, rod to stroke ratio determining how much 2nd order vibration, as well as how much stroke impacting the amplitude of those harmonics, (buzzy like big displacement four cylinder engines).

2) Cost of the crank and slightly more cost for the custom cam.

3) Complexity added to the project.

Dual Plane;

Pros;

1) Much smoother from a vibration/harmonics standpoint.

2) Readily available.

3) Exhaust note, (this is more of a personal taste thing)

4) Longer stroke/larger displacements without added buzziness.

Cons;

1) For given stroke, has more mass in the counterweights. Slower revs, but smoother.

2) For me anyhow, the exhaust note is a con. (Again, this is more of a personal taste than a performance aspect)

I apologize if I'm boring you guys or spewing too much...

Paul,I believe you and Jac are right about the V6 common pin set up.As soon as I read your comment about 'odd firing order' I remembered these were called by exactly that name;either odd fire or even fire . Thanks for the illustrations as well. A.J.

Al Jones,

You’re welcome, glad the pics/illustraions helped.:thumbsup:

Paul, on the other site you linked in your first post there was another poster who was IIRC able to source a number of new? flat plane cranks as used in the 'INDY FORD' V8 '260' cu in program.

I can think of several guys on this forum who might be interested in purchaseing some of these with a view to building a SBF along these lines. Bore & Stroke on these was 3.800" x 2.87" for the Indy version, but Bruce Mclaren also used some of the DOHC versions at 3 liters ( 183 cu in )for formula 1--- sorry but I dont know the bore or stroke dimensions on that one.

I can think of several guys on this forum who might be interested in purchaseing some of these with a view to building a SBF along these lines. Bore & Stroke on these was 3.800" x 2.87" for the Indy version, but Bruce Mclaren also used some of the DOHC versions at 3 liters ( 183 cu in )for formula 1--- sorry but I dont know the bore or stroke dimensions on that one.

I did want to add a little more pertaining to the "single plane/180 degree/flat plane" crank vs "180 degree" headers, for use in a GT40.

In all my research into actually building a domestic V-8 with a single plane crankshaft, and the little research I have done regarding 180 degree headers, my opinion is the 180 degree headers are a win win on pretty much all levels. With 180 degree headers, you can have your displacement, exhaust tuning, and exhaust note too.

No 2nd order vibrations buzzing the car, no incurred added cost for the custom crank, cam, and possibly a block that we are sure would handle the added stress of the 2nd order buzzzz of a typical displacement domestic V-8, pistons and rods if an odd ball stroke is used, etc. And, not too mention, the GT40 has room for the most gorgeous of exhaust systems, over the top 180 headers.

No 2nd order vibrations buzzing the car, no incurred added cost for the custom crank, cam, and possibly a block that we are sure would handle the added stress of the 2nd order buzzzz of a typical displacement domestic V-8, pistons and rods if an odd ball stroke is used, etc. And, not too mention, the GT40 has room for the most gorgeous of exhaust systems, over the top 180 headers.

With that said, I guess the only reason a GT40 owner might want a 180 degree crank vs 180 degree headers is the overwhelming desire to travel down a road less/rarely traveled, and is willing to tolerate the financial and vibration compromises that will accompany such a project. Some like myself are willing to make some sacrifice, mainly due to not having in the space for the headers...

Time for dinner,

Paul

In all my research into actually building a domestic V-8 with a single plane crankshaft, and the little research I have done regarding 180 degree headers, my opinion is the 180 degree headers are a win win on pretty much all levels. With 180 degree headers, you can have your displacement, exhaust tuning, and exhaust note too.

With that said, I guess the only reason a GT40 owner might want a 180 degree crank vs 180 degree headers is the overwhelming desire to travel down a road less/rarely traveled, and is willing to tolerate the financial and vibration compromises that will accompany such a project. Some like myself are willing to make some sacrifice, mainly due to not having in the space for the headers...

Time for dinner,

Paul

Last edited:

Paul, on the other site you linked in your first post there was another poster who was IIRC able to source a number of new? flat plane cranks as used in the 'INDY FORD' V8 '260' cu in program.

I can think of several guys on this forum who might be interested in purchaseing some of these with a view to building a SBF along these lines. Bore & Stroke on these was 3.800" x 2.87" for the Indy version, but Bruce Mclaren also used some of the DOHC versions at 3 liters ( 183 cu in )for formula 1--- sorry but I dont know the bore or stroke dimensions on that one.

We posted within one minute of each other...

this would be a great reason for the 180 degree crank as well. Don’t let me deter anyone else from pursuing this.

I’m awaiting a response from that individual you mentioned… stay tuned…

A bit of updated information from my end....

I found a local engine builder with lots of good experience custom building cranks and cams, including flat plane cranks for custom ferrari installs. They have the requisite CAD software, data bank of designs/profiles, CNC machines and track record of success. Trouble is (there's always a catch!) they want between $10,000 and $15,000 for just the crank work and another $5,000 - $7,500 for the camshaft. Ouch.

OK, so before moving forward with the process I have to ask one basic question: will a flatplane crank V8 make more power, or just spin up faster? I realize there's a relationship between these two phenomena, and an engine that spins up faster with less rotational mass will feel like it's making more power. So, what I'm really asking is does the flatplane crank make more power (spin up aside)? Or, merely just spin up faster?

I'm thinking an aluminum block 306 of the design that JacMac suggested is a good way to go - the right balance of displacement, economy (some off-the-shelf parts) and sophistication (manageable). I'm guessing this is going to be about a $25,000 motor... And, yes, part of the appeal is just to do something different.

I found a local engine builder with lots of good experience custom building cranks and cams, including flat plane cranks for custom ferrari installs. They have the requisite CAD software, data bank of designs/profiles, CNC machines and track record of success. Trouble is (there's always a catch!) they want between $10,000 and $15,000 for just the crank work and another $5,000 - $7,500 for the camshaft. Ouch.

OK, so before moving forward with the process I have to ask one basic question: will a flatplane crank V8 make more power, or just spin up faster? I realize there's a relationship between these two phenomena, and an engine that spins up faster with less rotational mass will feel like it's making more power. So, what I'm really asking is does the flatplane crank make more power (spin up aside)? Or, merely just spin up faster?

I'm thinking an aluminum block 306 of the design that JacMac suggested is a good way to go - the right balance of displacement, economy (some off-the-shelf parts) and sophistication (manageable). I'm guessing this is going to be about a $25,000 motor... And, yes, part of the appeal is just to do something different.

I love the flat plane thread (and sound for that matter), but if the goal is to go fast and your package is a SBF (or SBC) and you have a budget it seems like your value of go fast money can be better spent. Again, that is if that is your main goal for the fun that is absolutly not in question to do something very unique and cool.

My main goal is not to wreck while I'm passing everyone but that's another story but I'm going to stuff as much HP as I can in the package space available. If you really look at what you can churn out of some low cost parts these days it's really tough to look elsewhere for hp and if that is the goal make most HP in a standard package seems like a 4.125 bore block and a big crank is the cheep way to do it. Nothing exotic, but lots of easy HP. I just did the mustang motor 347 and with the crappy Canfield heads did about 575, left a bunch more on the dyno due to some lazy tuning at the top end. Most everything off the shelf except pistons. Same motor with better heads and nicer crank did 620 bumping in to 8K Rpm, and I'll tell you that sounds pretty good with or without xpipe/bundle of snakes etc.

but I'm going to stuff as much HP as I can in the package space available. If you really look at what you can churn out of some low cost parts these days it's really tough to look elsewhere for hp and if that is the goal make most HP in a standard package seems like a 4.125 bore block and a big crank is the cheep way to do it. Nothing exotic, but lots of easy HP. I just did the mustang motor 347 and with the crappy Canfield heads did about 575, left a bunch more on the dyno due to some lazy tuning at the top end. Most everything off the shelf except pistons. Same motor with better heads and nicer crank did 620 bumping in to 8K Rpm, and I'll tell you that sounds pretty good with or without xpipe/bundle of snakes etc.

That all being said, who is stepping up to get that crank made, Mr. Mac better get that billet blob of steel on a lathe and get to work!

BTW someone should resurect the Diesel thread, I love the v12 Audi R8 proto with the diesel, that would be sweet music...

Amped up a bit on coffee tonight, love this thread!

My main goal is not to wreck while I'm passing everyone but that's another story

That all being said, who is stepping up to get that crank made, Mr. Mac better get that billet blob of steel on a lathe and get to work!

BTW someone should resurect the Diesel thread, I love the v12 Audi R8 proto with the diesel, that would be sweet music...

Amped up a bit on coffee tonight, love this thread!

You both raise valid points & there is no real justification to do it for a GT40 unless you are locked into a capacity limit of say 5000cc or less & racing against others limited by that and perhaps a tire & weight rule as well.

Then you would have good reason because all 'racing' is really about acceleration/corner speed/braking. Since the flat plane has less mass the acceleration factor is a given & as the secondary imbalance factor can be reduced by the short stroke/long rod factor , then a large bore will enable the short stroke & the ability to rev higher which in turn will dictate shorter primary pipes in the exhaust system and the crossover design wouldnt be practicable anyway--then to take it one step further you would take advantage of this and fabricate the exhaust system to mount lower & forward in the car to lower the CG & keep weight within the wheelbase----- Of course by now its all starting to look like an SL-C instead of a GT40.

Unfortunately-or perhaps fortunately I have no good reason to build a motor of this type & at the end of the day a well sorted predictable handling car is worth more than a few HP especially in a longer race.

I have no good reason to build a motor of this type & at the end of the day a well sorted predictable handling car is worth more than a few HP especially in a longer race.

Then you would have good reason because all 'racing' is really about acceleration/corner speed/braking. Since the flat plane has less mass the acceleration factor is a given & as the secondary imbalance factor can be reduced by the short stroke/long rod factor , then a large bore will enable the short stroke & the ability to rev higher which in turn will dictate shorter primary pipes in the exhaust system and the crossover design wouldnt be practicable anyway--then to take it one step further you would take advantage of this and fabricate the exhaust system to mount lower & forward in the car to lower the CG & keep weight within the wheelbase----- Of course by now its all starting to look like an SL-C instead of a GT40.

Unfortunately-or perhaps fortunately

...

Unfortunately-or perhaps fortunatelyI have no good reason to build a motor of this type & at the end of the day a well sorted predictable handling car is worth more than a few HP especially in a longer race.

:thumbsup:

Further to the previous posts, the cranks that may have been available: If they are leftover's from the Ford Indy program they will be two plane conventional 289 style cranks as these motors used crossover exhaust systems . So only benefit would be if they are forged rather than cast. Looks like its back to the dwg board Sandy/Cliff-- send your deposits down & I will sharpen up my cold chisel!!

....

I’m awaiting a response from that individual you mentioned… stay tuned…

David gave his blessing to post the E-mail... :thumbsup:

Hope this helps...

351freak said:This is the message:

>

> Funny day...

>

> Called JE pistons to discuss a special piston they made to work with the TI rods I want...

>

> Talked to "Randy"...who turns out to be a Ford guy...and not only a Ford GUY...but also a guy that did a flat crank 30 years ago...!!! What are the friggin chances...

>

> His application flopped due to carb issues of the 70's and intake woes surrounding 180 degre pulses...but he was optimistic and never just gave up.

>

> He puts me in touch with Paul Marcovicci of Marcovicci-Wenz (big time race guys) who confirm Randy's story...

>

> Marcovicci-Wenz Home Page

>

> and...get this...

>

> He still has 2 brand damn new billet cranks setting there... 2.75" and 2.87" stroke for a 9,500 rpm application that they said they NEVER had any problems with (using the same cranks). These are brand new Moldex cranks...that would probably be 3k plus now. I will call "Whitey" at Moldex to confirm...since he is THE GUY that made them and is "THE" flat crank guy...it seems. (btw...was told they only need a small elastomeric dampner...we'll see)

>

> Dude...you OWE me... ;-)

>

> Hit me up some time...we got to chat about this stuff...

>

> (xxx)-xxx-xxx

> I'm in Atlanta GA.

> -….

>

***edit*** David also wanted me to throw this blurb in as well...

351freak said:Add to the JE piston blurb that it was a “piston guided” design to keep the TI rods from rubbing on each other.

Last edited:

You both raise valid points & there is no real justification to do it for a GT40 unless you are locked into a capacity limit of say 5000cc or less & racing against others limited by that and perhaps a tire & weight rule as well.

(Conversation at the race track)

Q: What are you running in that thing?

A: SBF

Q: Sounds good, how big?

A: 289 + 0.30

Q: Man she screams

A: Yeah, could use more cubes (snicker)

What I'm really running is not close and I'm going to have to cheat just like other guy's ;-) I think it is a lot more common the I would even guess.

I agree, I would have the, as I'll call it, dumb big HP, and put money into brakes, and handling, etc. And for me driving lessons and a thicker roll bar...

Sandy

Some incremental progress here - the builder has agreed to start the crank and cam machining and I've made an upfront payment to get it stared. We'll be using the specs suggested by JacMac for displacement, stroke, etc.

No guarantees with this project - it may just sound like a basic GT40 bundle of snakes exhaust and wind up slightly faster than your average SBF, all at great expense and effort. But, it's better than gambling or doing drugs.... When the crank and cam are machined I'll post some pics.

No guarantees with this project - it may just sound like a basic GT40 bundle of snakes exhaust and wind up slightly faster than your average SBF, all at great expense and effort. But, it's better than gambling or doing drugs.... When the crank and cam are machined I'll post some pics.

I'd love to see somebody do this. I would recommend anyone serious about it have a chat with the folks at Crower. I had a nice discussion with a very knowledgeable person there once about a flat-plane SBF, and he also suggested using a good rod/stroke ratio, e.g., a short stroke in a 4.125" bore, and the lightest reciprocating mass possible. He also told me the trick exhaust setup for a flat-plane crank V8 would be a tri-Y configuration.

Small update, I finally acquired a single plane V-8 crankshaft. The only info on it I have is this Billet piece was manufactured in 2000 by Bryant, ran in the late John Lingenfelters Pro Stock Truck engine program. It is a traditional Small Block Chevy crank, 2 piece rear main seal, small journal Mains and Rods, (2.30"/2.00"), Small Block snout, 3.240" stroke, was in a 358 CID engine that produced 900+ HP and ran mid 7's in the 1/4. I replaced my 300-ZX with a '97 BMW M3 and I am in the middle of converting the M3 to LSx power, (have the LSx and T-56 sitting in the car currently), once that is done, I will move forward with the single plane V-8 project. Ideally I would like to sell/trade this crank to have a single plane crankshaft built for my LSx in the M3.

The M3 LSx conversion build in this link;

Yet another LSx powered BMW E36, this one is a '97 M3 sedan! ;-) - Bimmerforums - The Ultimate BMW Forum

Here are some pics of my Single plane Small Block Chevy crankshaft.

The M3 LSx conversion build in this link;

Yet another LSx powered BMW E36, this one is a '97 M3 sedan! ;-) - Bimmerforums - The Ultimate BMW Forum

Here are some pics of my Single plane Small Block Chevy crankshaft.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 10

- Views

- 3K