I have an old issue of Circle Track in which someone asked Smokey Yunick about using a flat crank. To summarize, he spent many years and alot of money trying to make it work. In the end it was a break even proposition at best and the dual plane crank with a standard firing order usually came out on top performance and reliability wise. I will have to find the article to dig a little deeper into his answer but as I recall that was the gist of it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flat plane crank in a SBF?

- Thread starter Cliffbeer2

- Start date

In all my research on 180 degree cranks to the point of actually acquiring one, from a performance standpoint, RG’s summation matches not only what I recall reading from Smokey, but also from other sources such as my phone conversation with Mr. David Vizard, etc. Single plane cranks offer no real performance advantage over a dual plane crank, (outside of the uber small displacement V-8s used in the upper echelons of racing such as F1, Indy etc), and when the stroke increases past say 2 1/2"-3" inches, the nod definitely starts to swing towards the dual plane crank for several reasons.

For our purposes in the private consumer market, (vs conglomerate backed racing efforts), being as the dual plane crank is the standard for domestic V-8’s from production engines to huge-by-large top fuel V-8's, for what little weight savings can be had with the lighter counterweights on the crank in a single plane design, the dual plane offers advantages in reduced harmonics that far out weigh any advantages the exhaust tuning benefits and lighter weight counterweights of a single plane could offer. The bigger the displacement, the more this holds true.

In all honesty, anyone who goes to the lengths to build a single plane V-8 using a foundation that primarily did not come with a single plane crank, even if it is just a weekend warrior, is either whacked out of his head, or just really bent on having a V-8 that is just a little bit different than the rest, at a steep financial and time consuming toll. At that, the end result will still only perform mediocre at best compared to a comparably built, much less expensive dual plane variant.

I tell everyone that nows my ploy, that I fall into the latter category, but those who know me best, I'm sure think I also fall into the whacked category too some degree... :lipsrsealed:

If anyone else is contemplating this endeavor for a performance application, Keep in mind this is a huge consumption of time and money for no gain other than it is different. :shy: If a different exhaust note and the ability to fine tune exhaust pulses is your goal, you will much better served looking into 180 degree headers as that will gain you the best of all worlds, if space allows.

For our purposes in the private consumer market, (vs conglomerate backed racing efforts), being as the dual plane crank is the standard for domestic V-8’s from production engines to huge-by-large top fuel V-8's, for what little weight savings can be had with the lighter counterweights on the crank in a single plane design, the dual plane offers advantages in reduced harmonics that far out weigh any advantages the exhaust tuning benefits and lighter weight counterweights of a single plane could offer. The bigger the displacement, the more this holds true.

In all honesty, anyone who goes to the lengths to build a single plane V-8 using a foundation that primarily did not come with a single plane crank, even if it is just a weekend warrior, is either whacked out of his head, or just really bent on having a V-8 that is just a little bit different than the rest, at a steep financial and time consuming toll. At that, the end result will still only perform mediocre at best compared to a comparably built, much less expensive dual plane variant.

I tell everyone that nows my ploy, that I fall into the latter category, but those who know me best, I'm sure think I also fall into the whacked category too some degree... :lipsrsealed:

If anyone else is contemplating this endeavor for a performance application, Keep in mind this is a huge consumption of time and money for no gain other than it is different. :shy: If a different exhaust note and the ability to fine tune exhaust pulses is your goal, you will much better served looking into 180 degree headers as that will gain you the best of all worlds, if space allows.

Hi Paul,

I guess I must be wacked out in the head then. That's OK, I've done dumber things in the past. Many months ago I engaged a local builder to design and produce a flat plane crank for me for an SBF.

Here's the latest....unfortunately, there's nothing to really report other than the builder with whom I had engaged on this project seems to have left town for vacation around thanksgiving and hasn't been seen since. Several unreturned phone calls and emails. The shop still has machine tools in it (or so it looks, looking through a dusty/dirty window) but no signs of life at all. This place was doing a pretty good business a few years ago custom building all kinds of cranks and complete engines of all sorts.

Supposedly, production of the crank had begun in Aug/Sept but I'm beginning to think I'm going to be out my money here. I've made a couple of "progress" payments to this guy (but haven't paid the full estimated costs).

There's no doubt that a flat plane crank will spin up considerably faster given the dramatically lower counterbalance weight. And, if the engine is configured properly to take full advantage of that (higher revving, basically) then that translates into real-world seat-of-the-pants power advantage. The engine doesn't have to be a 20,000rpm F1 engine. A properly configured 7K SBF will derive some meaningful power gain here so I do have to partially disagree with Paul and, I guess, good ole' Smokey Yanuck. No doubt the dual plane crank has its own set of advantages including better harmonics (indeed, that's the main reason it's used in most non-race cars) but that doesn't mean a flat planer is useless.

And, the sound should be somewhat different with the flat plane crank. People do all kinds of crazy things for a different sound, just to try it out. The point isn't to just be different, it's to try to do something innovative and challenging and see what kind of success (or not) can be achieved. Without that we might all be driving flat head Fords with leather straps for fan belts and pouring our own babbit bearings late at night every 5,000 miles! I, unfortunately, don't have much positive to report here in this regard which is quite disappointing, aside from losing some money on it.

I guess I must be wacked out in the head then. That's OK, I've done dumber things in the past. Many months ago I engaged a local builder to design and produce a flat plane crank for me for an SBF.

Here's the latest....unfortunately, there's nothing to really report other than the builder with whom I had engaged on this project seems to have left town for vacation around thanksgiving and hasn't been seen since. Several unreturned phone calls and emails. The shop still has machine tools in it (or so it looks, looking through a dusty/dirty window) but no signs of life at all. This place was doing a pretty good business a few years ago custom building all kinds of cranks and complete engines of all sorts.

Supposedly, production of the crank had begun in Aug/Sept but I'm beginning to think I'm going to be out my money here. I've made a couple of "progress" payments to this guy (but haven't paid the full estimated costs).

There's no doubt that a flat plane crank will spin up considerably faster given the dramatically lower counterbalance weight. And, if the engine is configured properly to take full advantage of that (higher revving, basically) then that translates into real-world seat-of-the-pants power advantage. The engine doesn't have to be a 20,000rpm F1 engine. A properly configured 7K SBF will derive some meaningful power gain here so I do have to partially disagree with Paul and, I guess, good ole' Smokey Yanuck. No doubt the dual plane crank has its own set of advantages including better harmonics (indeed, that's the main reason it's used in most non-race cars) but that doesn't mean a flat planer is useless.

And, the sound should be somewhat different with the flat plane crank. People do all kinds of crazy things for a different sound, just to try it out. The point isn't to just be different, it's to try to do something innovative and challenging and see what kind of success (or not) can be achieved. Without that we might all be driving flat head Fords with leather straps for fan belts and pouring our own babbit bearings late at night every 5,000 miles! I, unfortunately, don't have much positive to report here in this regard which is quite disappointing, aside from losing some money on it.

Last edited:

Bill Kearley

Supporter

Over a year of interesting discution and education...........

But in my small mind nothing can come close to the after breakfast digestion aid

thunder that was available standing on the overpass at Westwood in the good old days of trans am Loved it

But in my small mind nothing can come close to the after breakfast digestion aid

thunder that was available standing on the overpass at Westwood in the good old days of trans am Loved it

Hi Paul,

I guess I must be wacked out in the head then. That's OK, I've done dumber things in the past. Many months ago I engaged a local builder to design and produce a flat plane crank for me for an SBF.

Here's the latest....unfortunately, there's nothing to really report other than the builder with whom I had engaged on this project seems to have left town for vacation around thanksgiving and hasn't been seen since. Several unreturned phone calls and emails. The shop still has machine tools in it (or so it looks, looking through a dusty/dirty window) but no signs of life at all. This place was doing a pretty good business a few years ago custom building all kinds of cranks and complete engines of all sorts.

Glad to hear you got started, I am also very sorry hear that progress has stopped. Were hoping that shop is just experiencing a temporary set back and will be back up and running soon. Keep us posted.

And, the sound should be somewhat different with the flat plane crank. People do all kinds of crazy things for a different sound, just to try it out. The point isn't to just be different, it's to try to do something innovative and challenging and see what kind of success (or not) can be achieved. Without that we might all be driving flat head Fords with leather straps for fan belts and pouring our own babbit bearings late at night every 5,000 miles! I, unfortunately, don't have much positive to report here in this regard which is quite disappointing, aside from losing some money on it.

That is exactly the reason I am doing it myself. For the sound and as an engine builder machinist, the challenge of the road less traveled is attractive.

have you done any research regarding the camshaft yet?

In my very little bit of research thus far, cam is going to be spendy, in the $900+ range. Typical cam blanks have the rough lobe shapes already formed and for Chevy also includes the 4-7 swap and of just recent, the 2-3 swap, (mimicking the LSx firing order which as I understand is the same “sequence” as the non HO SBF of the ’80—‘90’s). Any how, cam for the revised firing order will have to be from Billet stock, shaped, heat treated, straightened etc.

For the time being, my SBC flat plane cranks stands next to my night stand in the bedroom until I get my daily driver project finished, (installing and LSx in my '97 BMW M3), then I’ll move full swing into my single plane SBC V-8.

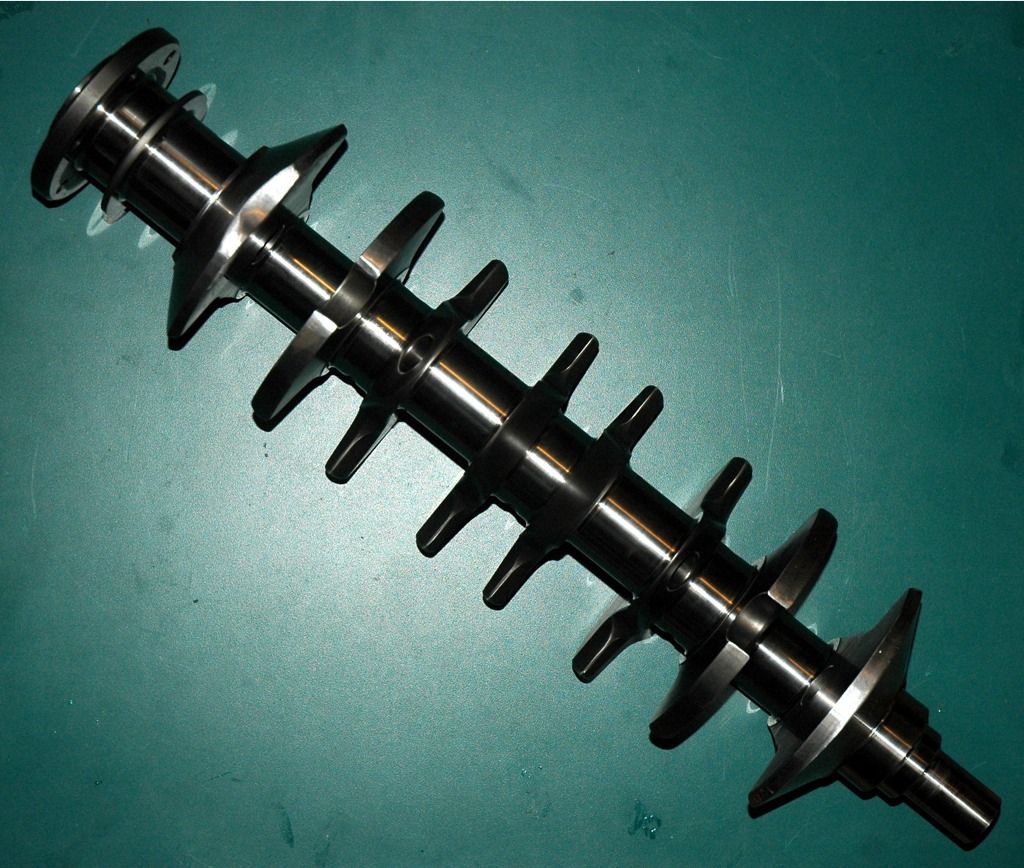

Couple more shots of my new small journal single plane SBC crank… For an engine guy, it is looks so much cooler in person than pics.

I think the vibration might be hard to live with. Just read John Horsmans "racing in the rain" and when they fitted 3.0 DFV Cosworth to a '40 and to a Mirage M1, apparantly it shook all the instruments to bits and they had to devise way of soft mounting them.

Probably need to get special fillings for your teeth too!

I'm quite a fan of the concept however and a long time fan of SY, one the cleverest "outside the box" thinking auto engineers ever IMO, and if he couldn't find any advantage then it's doubtful whether there would be any.

Remember also, that everyone was banging on about 4V per cylinder OHC but he proved there was no significant advantage over the CIB, probably one of the reasons that GM still haven't gone down that route.

Still, as y'all say, if you've got money in the bank and time on your hands, why not?

Probably need to get special fillings for your teeth too!

I'm quite a fan of the concept however and a long time fan of SY, one the cleverest "outside the box" thinking auto engineers ever IMO, and if he couldn't find any advantage then it's doubtful whether there would be any.

Remember also, that everyone was banging on about 4V per cylinder OHC but he proved there was no significant advantage over the CIB, probably one of the reasons that GM still haven't gone down that route.

Still, as y'all say, if you've got money in the bank and time on your hands, why not?

Hi Paul, that's super nice work there - looks beautiful. A real piece of stunning craftsmanship there. That's exactly what I was hoping to end up with as well. While I do some machine work of my own, I lack the skills to produce anything close to what you have done (hence I had to engage an outside shop for the intended work).

As far as cam work, that was also on the agenda with my shop but no actual production had begun (as far as I know). We had settled upon a couple different profiles to be produced - was planning on trying both. Specifically, the theme was modest lift, and most ramp, the goal being to try to get a valve train which will turn as high as possible before floating valves or rocker arms. One was basically a very modest profile, and the other just slightly more aggressive (little more total lift, little more open profile), with both configured to work with the piston timing of the flat crank. Obviously, my approach is kind of low-tech, if not plain old amateur!

My grand plan for all of this really was to be able to put this high-revving flat plane engine in an old Indy car or F5000 chassis (where you expect a fair bit of harmonic vibration) and have kind of a unique and extreme track day car. Unfortunately, my grand plan has suffered a few practical setbacks along the way!

Anyway, love to see how you progress with your flat plane project, and I'll be taking close notes!

As far as cam work, that was also on the agenda with my shop but no actual production had begun (as far as I know). We had settled upon a couple different profiles to be produced - was planning on trying both. Specifically, the theme was modest lift, and most ramp, the goal being to try to get a valve train which will turn as high as possible before floating valves or rocker arms. One was basically a very modest profile, and the other just slightly more aggressive (little more total lift, little more open profile), with both configured to work with the piston timing of the flat crank. Obviously, my approach is kind of low-tech, if not plain old amateur!

My grand plan for all of this really was to be able to put this high-revving flat plane engine in an old Indy car or F5000 chassis (where you expect a fair bit of harmonic vibration) and have kind of a unique and extreme track day car. Unfortunately, my grand plan has suffered a few practical setbacks along the way!

Anyway, love to see how you progress with your flat plane project, and I'll be taking close notes!

I haven't read all of the posts but wasn't the flat plane introduced because it was stronger and more durable for the extreme power of race engines, (thinking of the old Formula 5000 days)? Most of the forged dual plane cranks still had twisted journals.

Light weight, less inertia & the bonus of getting even fire ( 180° ) pulses on each bank, plus remember none of those motors were more than 3" stroke were the main reasons @ the time.

Making cranks out of a billet or 6" dia chunk of steel was not always a happy deal, quite often flaws (inclusions or voids ) in the metal would render weeks of work useless. That said I found a chunk of 4340 that would be ideal for a short stroke SBF crank, all I need now is a reason & $$$ to do it, lucky thats not on the horizon 2 moment

Brian Hamilton

I'm on the verge of touching myself inappropriatel

Ok,

From what I've read the flat plane crank seems like it would be fantastic for turbocharged applications. Especially a twin turbo engine as each bank is completely independent of the other. Is my thinking correct or am I way off? LOL

From what I've read the flat plane crank seems like it would be fantastic for turbocharged applications. Especially a twin turbo engine as each bank is completely independent of the other. Is my thinking correct or am I way off? LOL

Ok,

From what I've read the flat plane crank seems like it would be fantastic for turbocharged applications. Especially a twin turbo engine as each bank is completely independent of the other. Is my thinking correct or am I way off? LOL

JacMac and Paul and others will know more than I on this one but it seems to me that any situation where fast spool up is key is a good place for a flat plane crank. As you suggest, a turbo engine seems like a good candidate as the light weight of the flat plane may help get the revs up faster and lessen the turbo lag (or at least the sensation of turbo lag). I'm not sure if a twin turbo v. a single turbo makes that much of a difference, although many twin turbo setups these days are sequential in nature and therefore a little less suspectible to the ill effects of turbo lag (in other words, slow to build engine revs and spool the turbo).

Not sure I can think of any production flat plane turbos out there. The ferrari 288 GTO is one, but not really a production car, unless you consider a couple hundred "production."

Ok,

From what I've read the flat plane crank seems like it would be fantastic for turbocharged applications. Especially a twin turbo engine as each bank is completely independent of the other. Is my thinking correct or am I way off? LOL

Im not a Turbo fan, but I can see that having even exh pulses plus the ability to mount the turbos closer to those four ports with short manifolds would be a plus. less heat & gas speed loss, less weight , it all adds up to faster!!

I was recently involved in the same discussion looking for a flat crank engine for my pantera. I was told that the Porsche 928 has a flat plane crank. There are allot of those engines floating around in Junk yards for not too much money. They are V8 and the 1987 model and later were 5 liter dohc 32 valve with fuel injection. I would double check the flat plane design but this would certainly be a good place to start if you wanted something truly exotic.

Jim Rosenthal

Supporter

I was reading John Horsman's book "Racing In The Rain" recently. He describes the difficulties they had using Cosworth DF series V8s, which have a flat-plane crank. The first car they tested came back to the pits and the driver couldn't tell them anything about instrument readings, because the vibration had shaken all the needles off the gauges; the needles were lying at the bottom of the gauge faces. Evidently the vibration issue isn't a trivial one.

See post #66 Jim!

Further into the book, the Mirage M6 powered by a DFV, had its input shaft knackered by the excessive vibration causing the box to fail. Their diagnosis was that the shaft was too stiff and their solution was the mill down the shaft diameter so that it flexed in sympathy with the rest of the drivetrain!

And I thought the DFV had balance shafts.. Hmmmm.

Further into the book, the Mirage M6 powered by a DFV, had its input shaft knackered by the excessive vibration causing the box to fail. Their diagnosis was that the shaft was too stiff and their solution was the mill down the shaft diameter so that it flexed in sympathy with the rest of the drivetrain!

And I thought the DFV had balance shafts.. Hmmmm.

Just read this thread and had to have a say. I ran a F5000 for nearly ten years which had a flat plane crank for some of the time. Yes it had a little more HP, Yes the engine was used as a stressed member, and Yes it did vibrate, but believe me you had other things to worry about, like trying to save your life, so you hardly noticed it.

What you did notice, however, was the effect the thing had on the fastenings on the car. Everything came loose. You had to re-tighten all the nuts and bolts after every race, even nylocks. Changed it at rebuild time and can't say I really noticed the difference. My pit crew did comment that the exhaust note wasn't as good, but I sure couldn't tell.

What you did notice, however, was the effect the thing had on the fastenings on the car. Everything came loose. You had to re-tighten all the nuts and bolts after every race, even nylocks. Changed it at rebuild time and can't say I really noticed the difference. My pit crew did comment that the exhaust note wasn't as good, but I sure couldn't tell.

Ok boys. Circumstances and timing as they are, I am putting my single plane crankshaft up for sale. I am NOT abandoning the project as lined out here;

DIY 180 Degree/Single plane/Flat plane V-8 crankshaft? - HybridZ

... just putting it on hold for a while. Could be 3-5 years before I pick it back up. Who knows, next iteration may based on the SBF, LSx, BMW M60, VH45DE, or the SBC again.

Any how, for those that may be interested in the crankshaft, here is the ad;

For sale, VERY custom Bryant billet, single plane crankshaft for Small Block Chevy. - HybridZ

DIY 180 Degree/Single plane/Flat plane V-8 crankshaft? - HybridZ

... just putting it on hold for a while. Could be 3-5 years before I pick it back up. Who knows, next iteration may based on the SBF, LSx, BMW M60, VH45DE, or the SBC again.

Any how, for those that may be interested in the crankshaft, here is the ad;

For sale, VERY custom Bryant billet, single plane crankshaft for Small Block Chevy. - HybridZ

Dave Wood

Lifetime Supporter

Like many things over the years( overhead cams,4 valve heads,etc.)technology/metallurgy were not up to the demands they created.Many of these were created in auto infancy( early 1900s) and shelved until many decades later. I suggest the same with the flat crank. They were tried extensively at Indy in all sorts of engines with funding by companies with deeper pockets than I. If they couldn't get it to be worthwhile( Think about the $$$ Ford spent to win Indy and Lemans), which they couldn't, I haven't seen the advances in the above mentioned obstacles that has changed that.

My understanding of their reasons had nothing, of course, to do with exhaust note. It was believed at the time that since it basicly operated like 2 four cylinder engines, they had more torque coming out of the corners. That makes since in a small stroke high revving F1 engine, but it seems that all that development would have been re-applied if it was now feasible and beneficial. I doubt that it is.

My understanding of their reasons had nothing, of course, to do with exhaust note. It was believed at the time that since it basicly operated like 2 four cylinder engines, they had more torque coming out of the corners. That makes since in a small stroke high revving F1 engine, but it seems that all that development would have been re-applied if it was now feasible and beneficial. I doubt that it is.

Not sure how or why the debate over over single plane vs dual came up, yet again. The theory over any possible benefits or down side has been beat pretty hard. I have found in all discussions on this matter, especially for street applications, there really is no debate over its relevancy or practicality. The design does have its positive and negative attributes as outlined earlier in this thread and to an even greater degree in the thread linked below. It is not practical for a street application, mostly different and unique giving it some exoticness all to itself.

For what its worth, the flat plane crank V-8 is still today, very much in use in the upper echelons of automotive racing, not tried and then shelved. Its use is not because it is some mystical silver bullet, (it isn’t) but because its benefits as used in those specific applications outweigh the negative, again, covered already not only here but even to a much greater degree in the other discussion linked here;

DIY 180 Degree/Single plane/Flat plane V-8 crankshaft? - HybridZ

For what its worth, the flat plane crank V-8 is still today, very much in use in the upper echelons of automotive racing, not tried and then shelved. Its use is not because it is some mystical silver bullet, (it isn’t) but because its benefits as used in those specific applications outweigh the negative, again, covered already not only here but even to a much greater degree in the other discussion linked here;

DIY 180 Degree/Single plane/Flat plane V-8 crankshaft? - HybridZ

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 10

- Views

- 3K