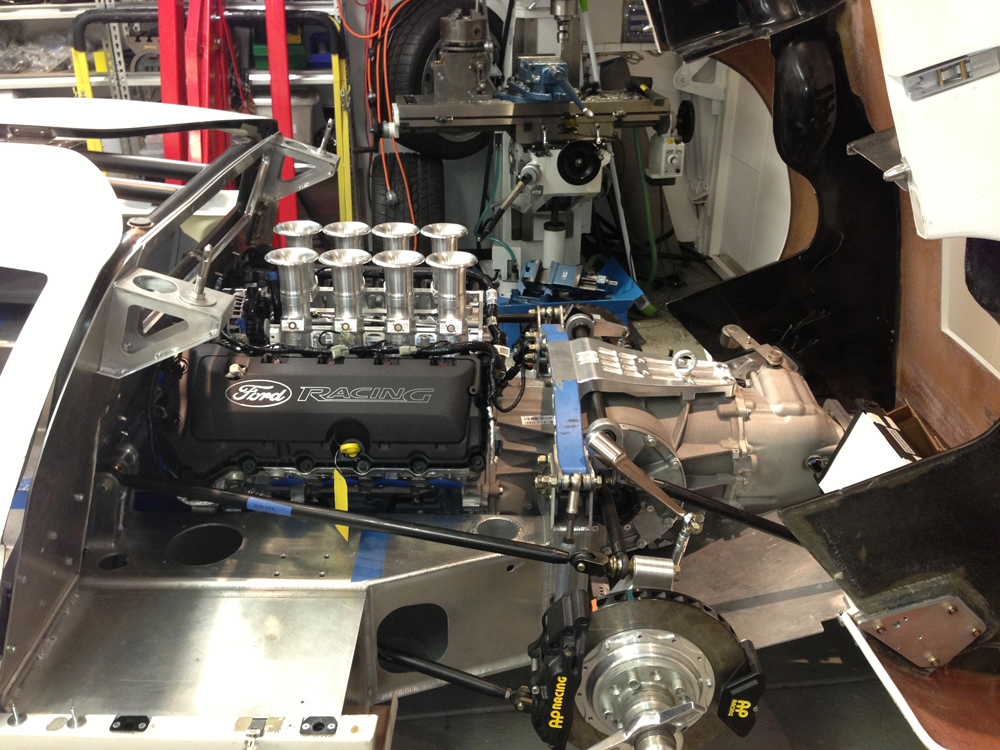

Hi Tom, I was going to look at adding them but they are really for serious racers and I can not drive to save myself! I think that when someone that knows how to drive helps me to tune the car I can just adjust them manually. Also finding room in the cabin for the adjusting levers is hard. Tom you may see another copy from your car below, I hope you don't mind? I also mocked up headers there is plenty of room (cross-over system with no catalytic converters and small mufflers).

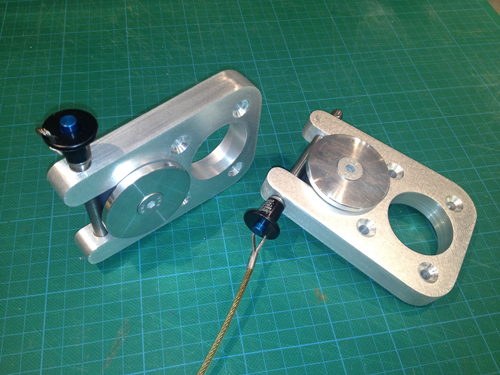

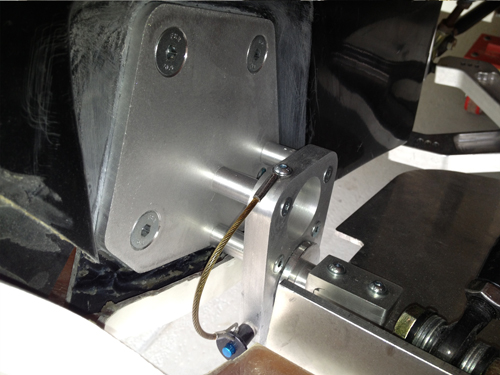

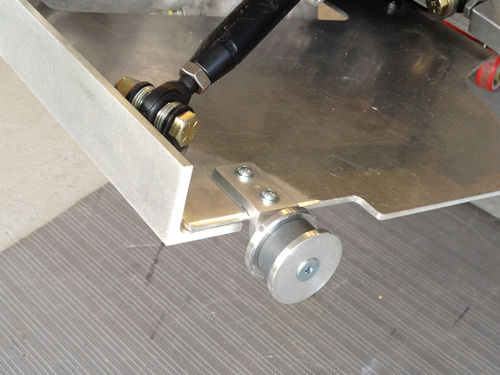

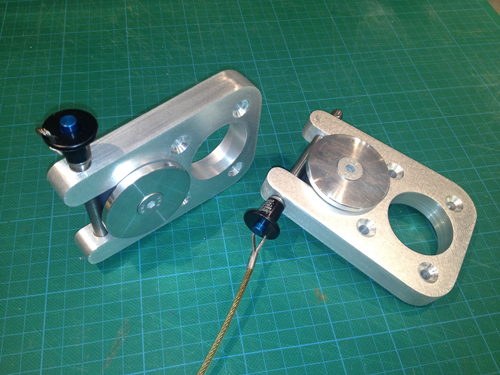

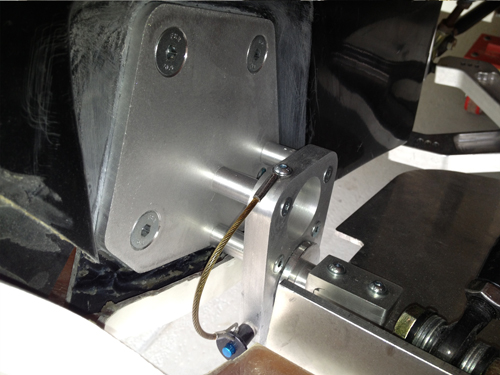

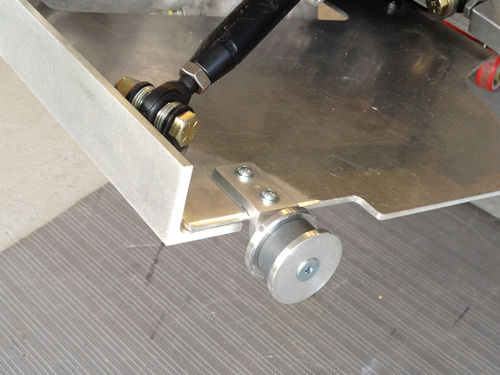

To make the removal of the rear clip easier I have made some rear mounts (shamelessly copied from other GT40's!). To remove the clip one just removes the Jergens quick release pin.

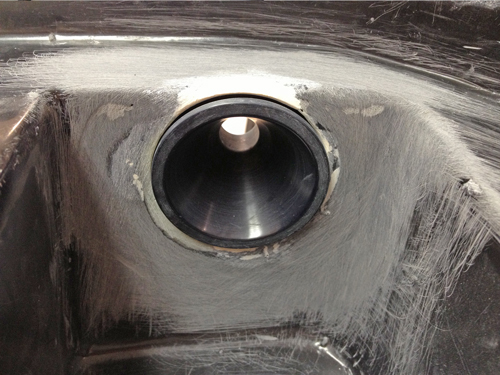

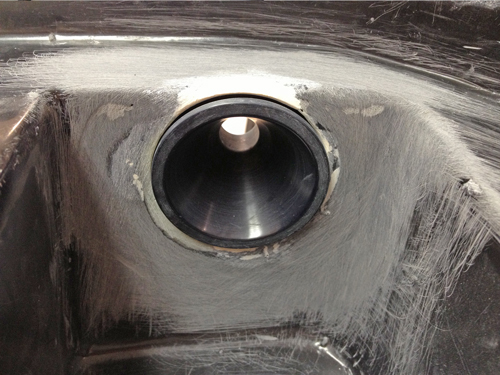

I also placed the hood pin caps on the body. To assist in closing without damage to the body I also bolted in nylon "pin guiding cones" under the clip. It allows me to just drop the clip into place and the cones ensure the pins guide easily into the neat holes.

To make the removal of the rear clip easier I have made some rear mounts (shamelessly copied from other GT40's!). To remove the clip one just removes the Jergens quick release pin.

I also placed the hood pin caps on the body. To assist in closing without damage to the body I also bolted in nylon "pin guiding cones" under the clip. It allows me to just drop the clip into place and the cones ensure the pins guide easily into the neat holes.