Hi Terry,

Is that weight with the hub installed? I think you will find there is not much weight to be saved doing them in alloy over the sheet steel as you need to be quite a bit thicker to get the same strength, I have now done some hollow core uprights and they are about 7 Kg I doubt I could get them much lighter with out going to Magnesium.

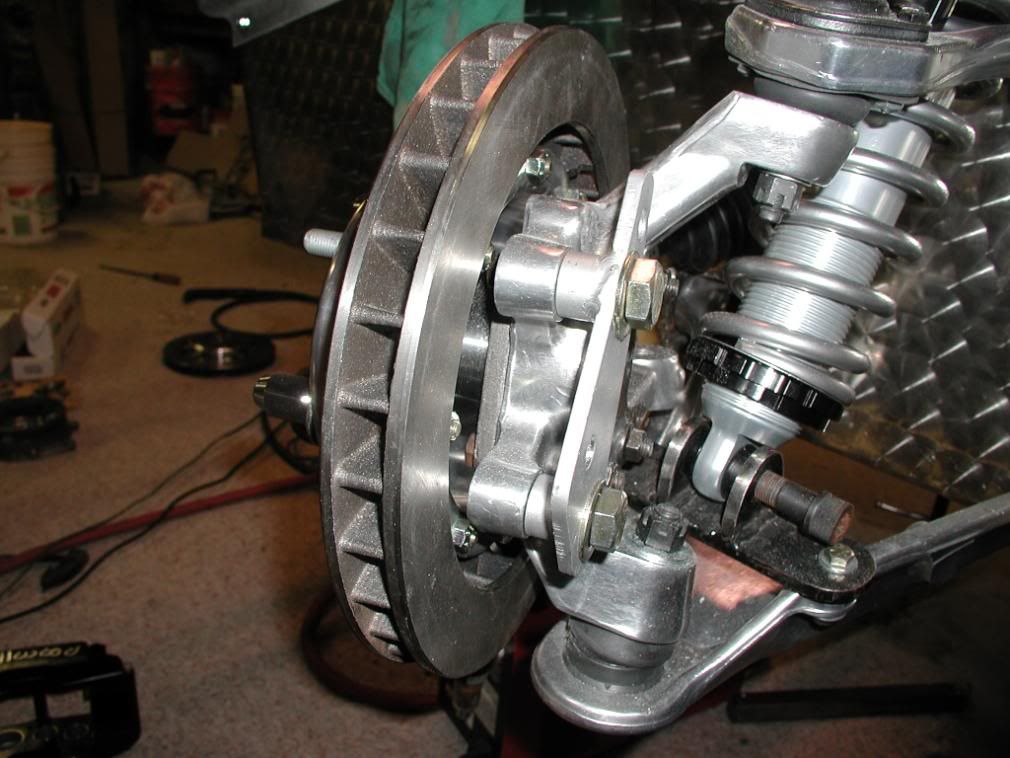

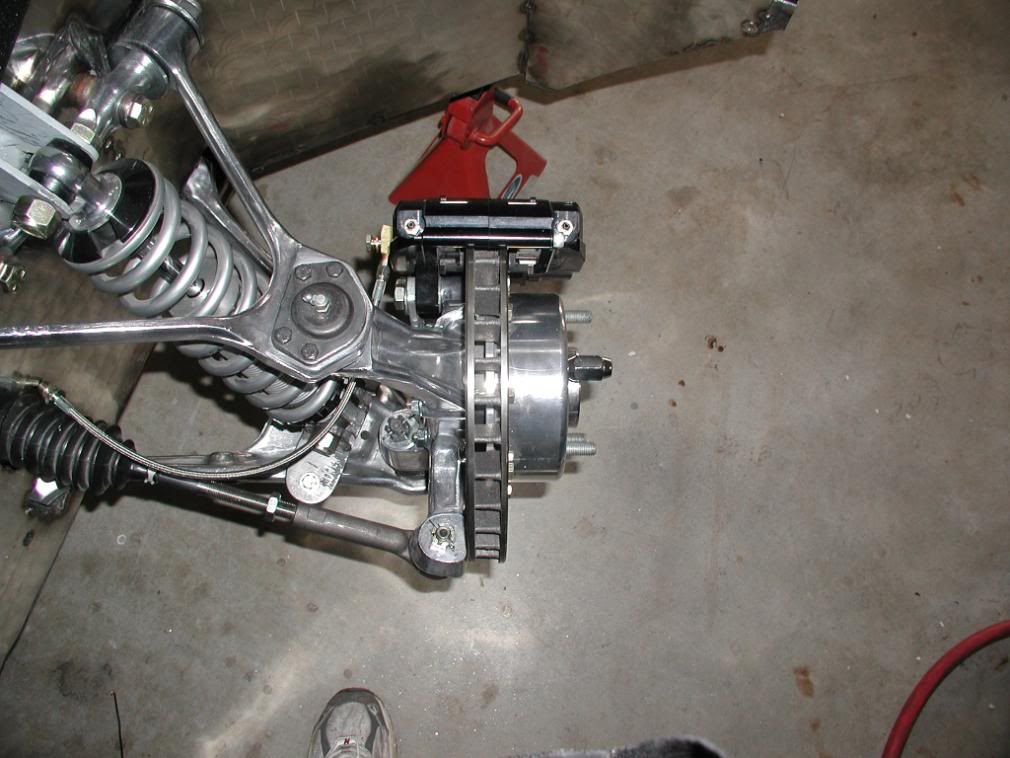

Very nice job.

Cheers Leon

Is that weight with the hub installed? I think you will find there is not much weight to be saved doing them in alloy over the sheet steel as you need to be quite a bit thicker to get the same strength, I have now done some hollow core uprights and they are about 7 Kg I doubt I could get them much lighter with out going to Magnesium.

Very nice job.

Cheers Leon