Ron Earp

Admin

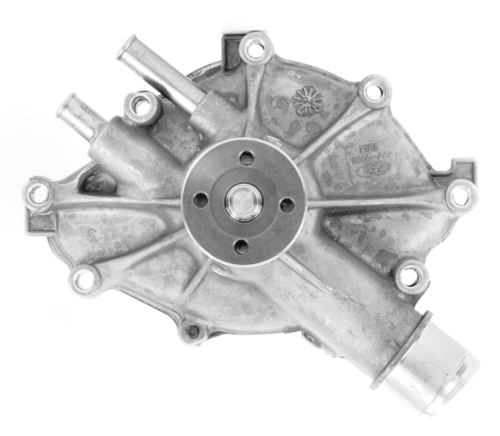

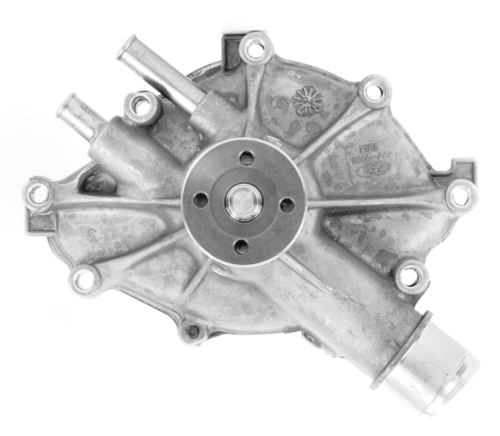

The new V6 I'm building for the Mustang has a number of water pump lines that need to be capped. Little short tubes like shown on the upper left of this pump:

In the past I've cut them off, plugged them with a metal plug, or, used a piece of heater hose with a pipe plug clamped in the end of it. Both solutions worked well.

But I don't want to cut the fittings off this time and I'd rather not redneck plug them with heater hose and a pipe plug. I might want to use the fittings for a the heater core later. Does anyone have any suggestions for an elegant solution here that would be reversible?

I found these at McMaster:

McMaster-Carr

But I'm not sure they can handle being clamped or what pressure the water system develops (< 15 psi I'm sure).

In the past I've cut them off, plugged them with a metal plug, or, used a piece of heater hose with a pipe plug clamped in the end of it. Both solutions worked well.

But I don't want to cut the fittings off this time and I'd rather not redneck plug them with heater hose and a pipe plug. I might want to use the fittings for a the heater core later. Does anyone have any suggestions for an elegant solution here that would be reversible?

I found these at McMaster:

McMaster-Carr

But I'm not sure they can handle being clamped or what pressure the water system develops (< 15 psi I'm sure).