You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

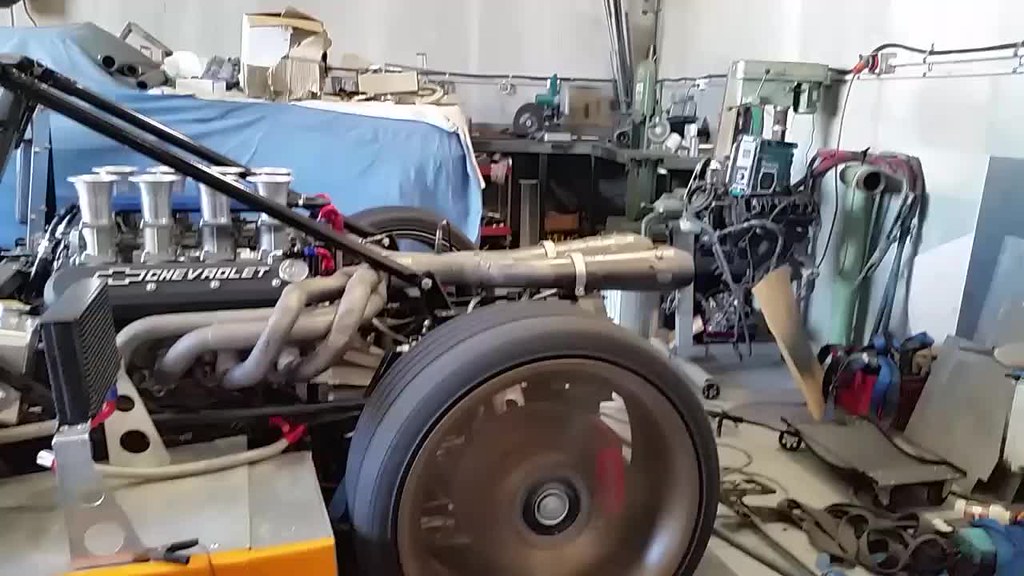

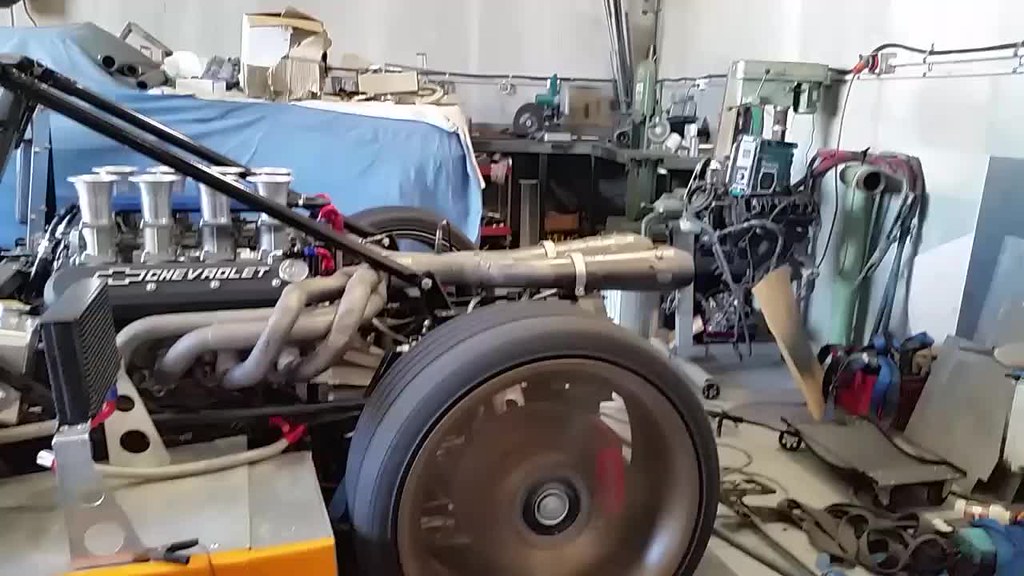

the Steinard MK3 takes shape

- Thread starter kaspa

- Start date

John, the car looks superb. Great stuff! Cheers, Andrew

The ole girl finaly made it to the dyno the other day, only got as far as tuning the mid range before a small whoopsie put and end to things, but so far at 4500 its making over 450hp and sounds great.

heres a short clip of the last pull before it all went pear shaped.

https://flic.kr/p/22hkMfD

https://flic.kr/p/22hkMfD

heres a short clip of the last pull before it all went pear shaped.

https://flic.kr/p/22hkMfD

https://flic.kr/p/22hkMfDHi Mate yep it will get his attention thats for sure, at 4500 its only just come onto the cam so theres plenty left in the cupboard.

whoopsie was a slight misconception in the torque loading on the trans, an extension to the lay shaft to carry a bearing was pressed on unsecured and it walked out. bugger, so its back over the ditch for a fix.

Cheers john

whoopsie was a slight misconception in the torque loading on the trans, an extension to the lay shaft to carry a bearing was pressed on unsecured and it walked out. bugger, so its back over the ditch for a fix.

Cheers john

Look up a book by William Milliken

Milliken Research Associates, Inc. -- "Race Car Vehicle Dynamics"

I’ll warn you now that it is not light reading, but you will come away well schooled!

Milliken Research Associates, Inc. -- "Race Car Vehicle Dynamics"

I’ll warn you now that it is not light reading, but you will come away well schooled!

Well the big day came for the Maccas debut at a historic street sprint meet, gear box came back from NZ all fixed so she was to be the star attraction of the meet and the gate prize for one lucky person was going to be a few hot laps in the ole girl.

But once again big problems Brett went out for a sighting run and on his third lap and just starting to use some throttle the trans locked up and spun him big time. they had to drop the axles to tow it back to the pit and when they drained the oil, a lot of teeth came out. not a very happy camper.

anybody no of a decent replacement that will handle 500ft lbs.

cheers John

But once again big problems Brett went out for a sighting run and on his third lap and just starting to use some throttle the trans locked up and spun him big time. they had to drop the axles to tow it back to the pit and when they drained the oil, a lot of teeth came out. not a very happy camper.

anybody no of a decent replacement that will handle 500ft lbs.

cheers John

Hi Neil yeah it looks like the diff has destroyed itself as the drain plug is directly under it and the broken teeth look like diff teeth, luckily he was braking for the hair pin and going from 2nd back to 1st when it locked up so speed was moderate, but enough to spin him around, just lucky he didn't hit anything, so that was a sizeable amount of money down the toilet, now we have the enviable task of finding something to replace it, have spoken to Fran and he has a box that will do the job so all is not lost, just another set back we didn't need. but on a plus the ole girl certainly got plenty of attention apparently, so that's a good sign.

When you say diff teeth, do you mean R&P or parts out of the LSD Tru Trac or whatever was used?Hi Neil yeah it looks like the diff has destroyed itself as the drain plug is directly under it and the broken teeth look like diff teeth, luckily he was braking for the hair pin and going from 2nd back to 1st when it locked up so speed was moderate, but enough to spin him around, just lucky he didn't hit anything, so that was a sizeable amount of money down the toilet, now we have the enviable task of finding something to replace it, have spoken to Fran and he has a box that will do the job so all is not lost, just another set back we didn't need. but on a plus the ole girl certainly got plenty of attention apparently, so that's a good sign.

When a Hypoid gear set suddenly gets a situation where the pinion backs out of mesh ( say for example the taper roller bearing nearest the pinion moves or wears quickly ) the tooth curvature will result in high point loadings as the two curves of R&P will now not be in phase- Ive seen this happen on 9'' R&P where the pinion retainer bolts are removed and an attempt to pull pinion assy from housing without moving ring gear out of mesh first. Thats with the trans/rear axle on bench, I can only guess at how much damage would ensue under load in service.Hi Jac, looks like crown wheel teeth apparently the diff is a Detroit locker.

cheers John

In pic below it shows a pinion support bearing, did Leon buy some of the modified R&P sets De Lynn had for sale where pinion is splined onto shaft?

Detroit Locker only has back cut dogs etc, nothing that looks like a R&P tooth.

Enlarged the pic, it would appear that he has used the pinion gear that De Lynn made and they are splined onto the shaft and that collar at end of pinion is actually a splined/threaded nut. Pinion rotation is correct, but would appear that he is using single ball race at rear end of pinion shaft for pinion mesh/depth control which I doubt would control end float enough be sufficient and subjects the pinion any dimension changes from case heat expansion of that longer section as well. At a guess those two factors plus any engine braking on the downshift could be enough to alter the pinion depth of engagement sufficiently to lead to the failure. Unless there is a steel bearing carrier for the bearing beside the pinion that acts as pinion depth control, but I see no evidence of that in other pics

Brett pulled a side cover off this morning and apart from a lot of pinion teeth lying on the bottom was this nut, but no sign of a lock tab.

looks like as you suspected Mac the nut has wound loose and then all hell broke loose, literaly.

John

looks like as you suspected Mac the nut has wound loose and then all hell broke loose, literaly.

John

Dont think its meant to have a lock-tab John, just need to be bloody tight and be done up with a special ring spanner that engages with those flutes on OD. Once the nut comes loose your on a highway to nowhere as failure of the pinion from inner splines to tooth root is inevitable as forces are generated in several directions.

Last edited:

Similar threads

- Replies

- 96

- Views

- 7K

- Replies

- 7

- Views

- 588

- Replies

- 4

- Views

- 427