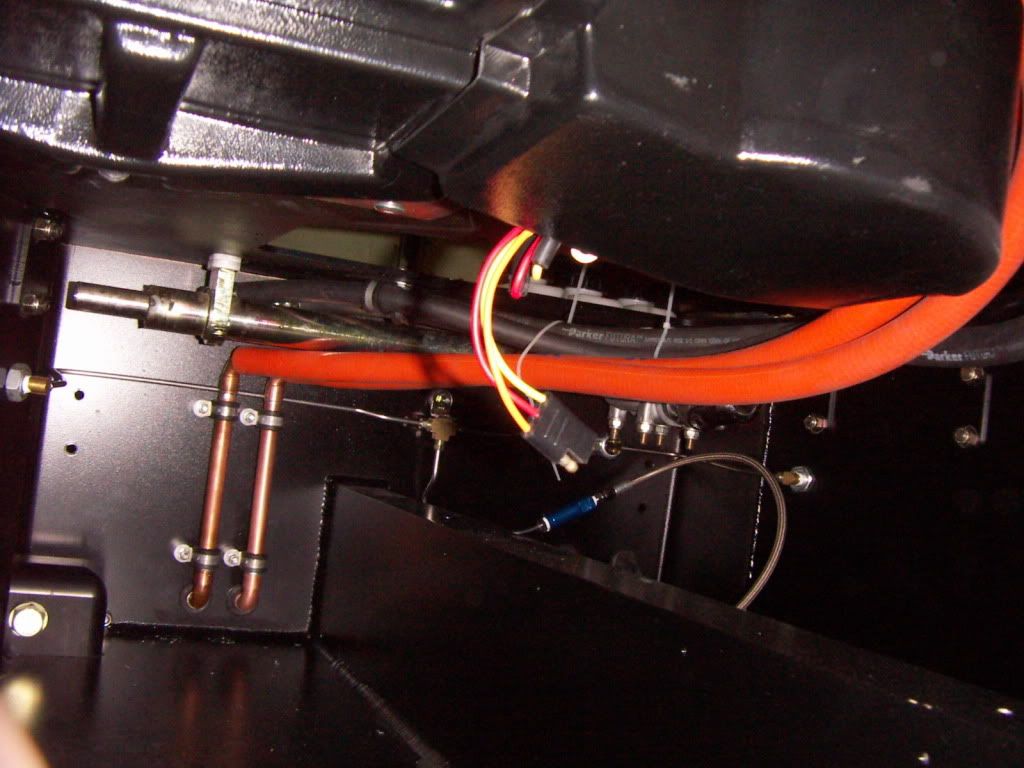

Tom:

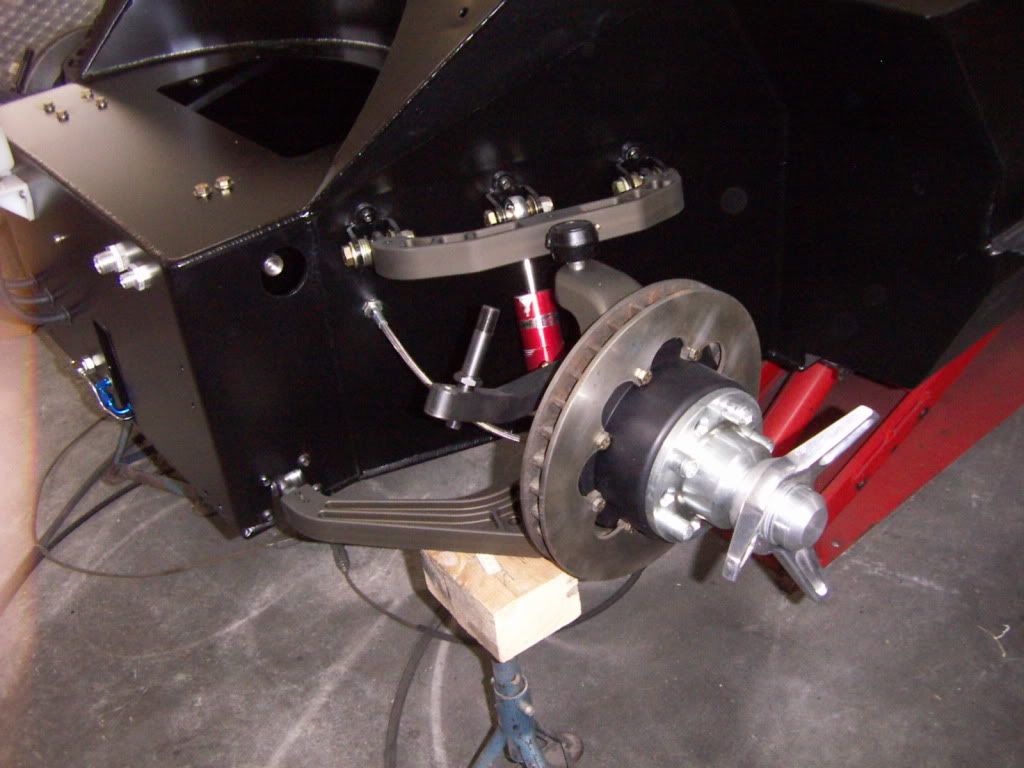

Excellent approach. Building, drilling, cutting, etc. and then dismanteling and painting is certainly the best way to go. No exposed surfaces. You keep raising the bar higher and higher . . . .

Chuck

Totally agree, a lot of work but the results look great. When are you hoping to have the car finished?

Trev