Chuck

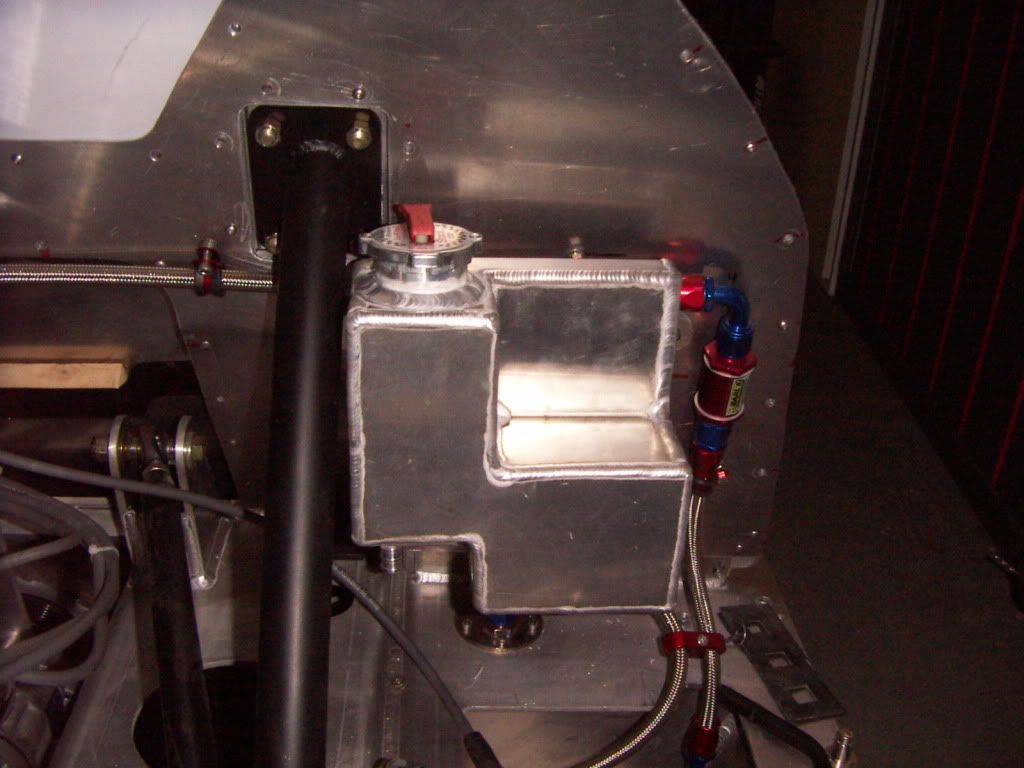

took your advice and made it smaller. Not much but about 25 %.

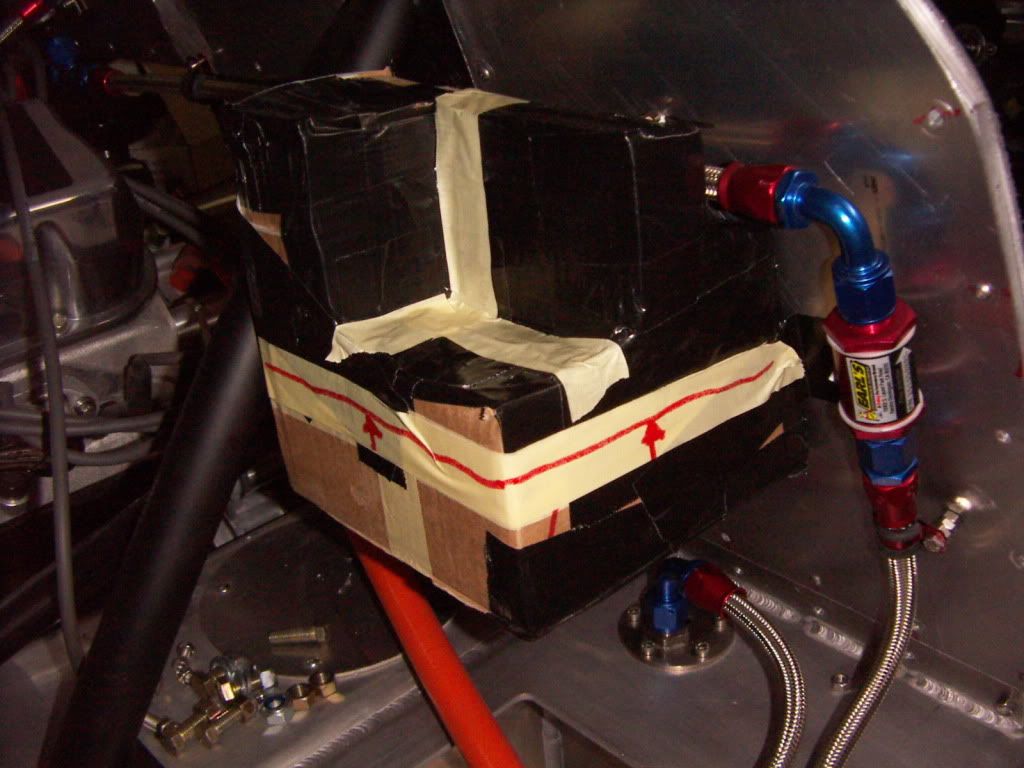

I also set the expansion tank higher.

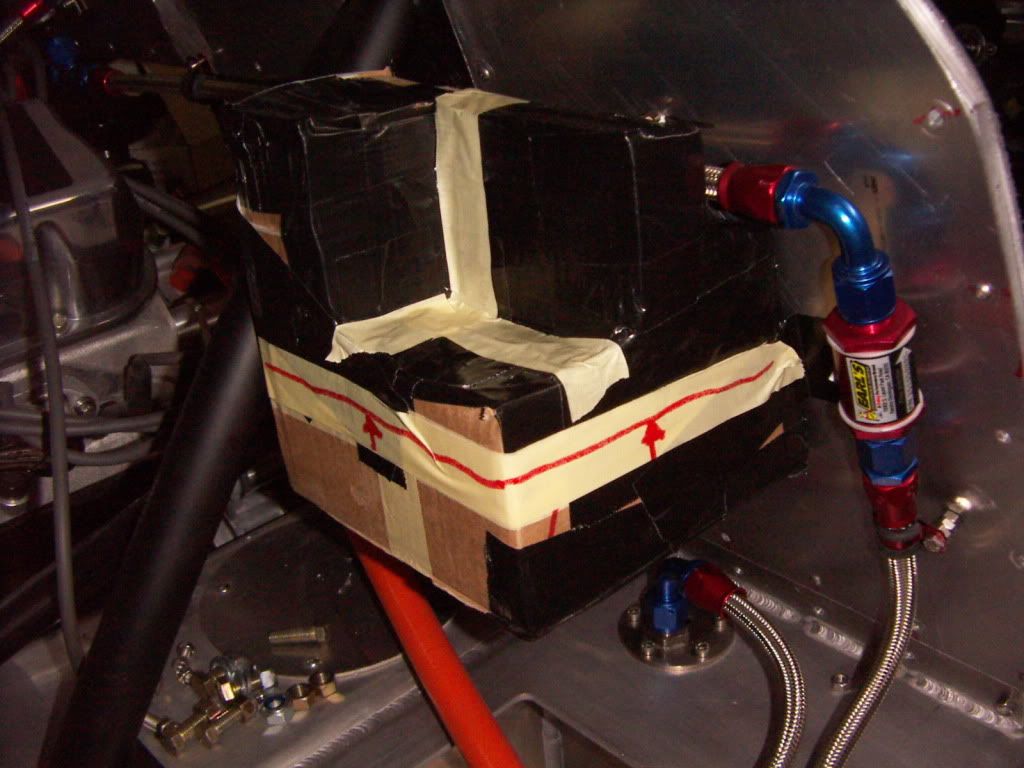

The bright tape and red line is marking the top of the thermostat housing level. The volume above is app 1,3 liter the volume below this level is 2 liter.

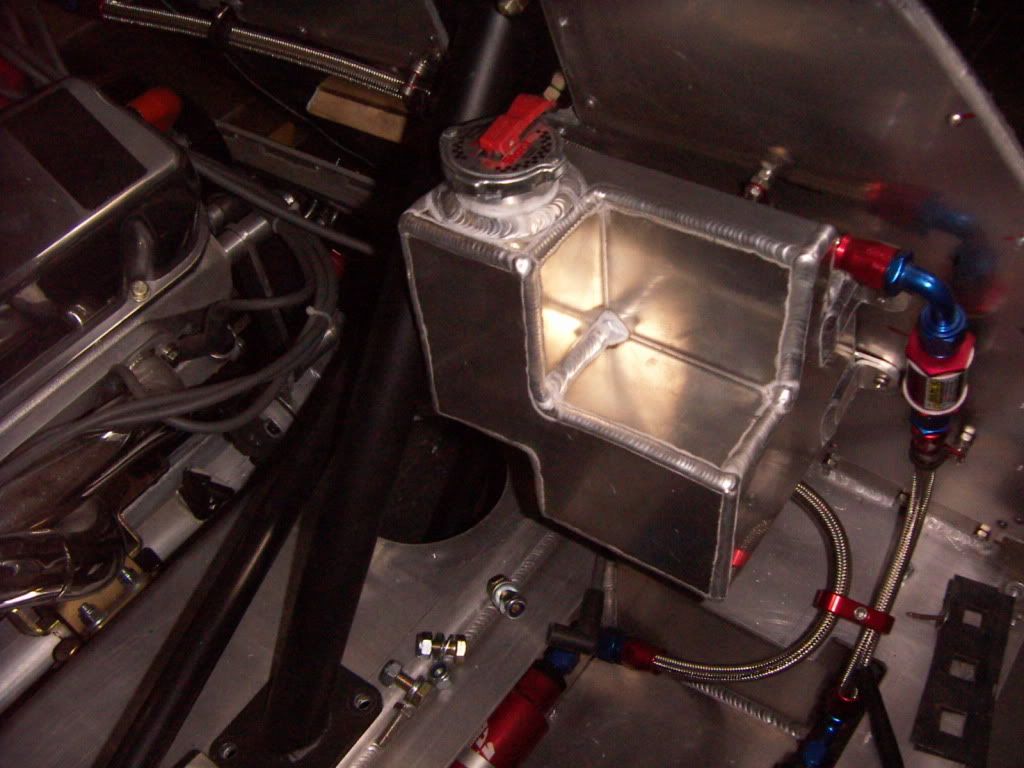

I won´t use a recovery tank so i designed the expansion tank in a way which enable it to fully cover the expansion without overflow.

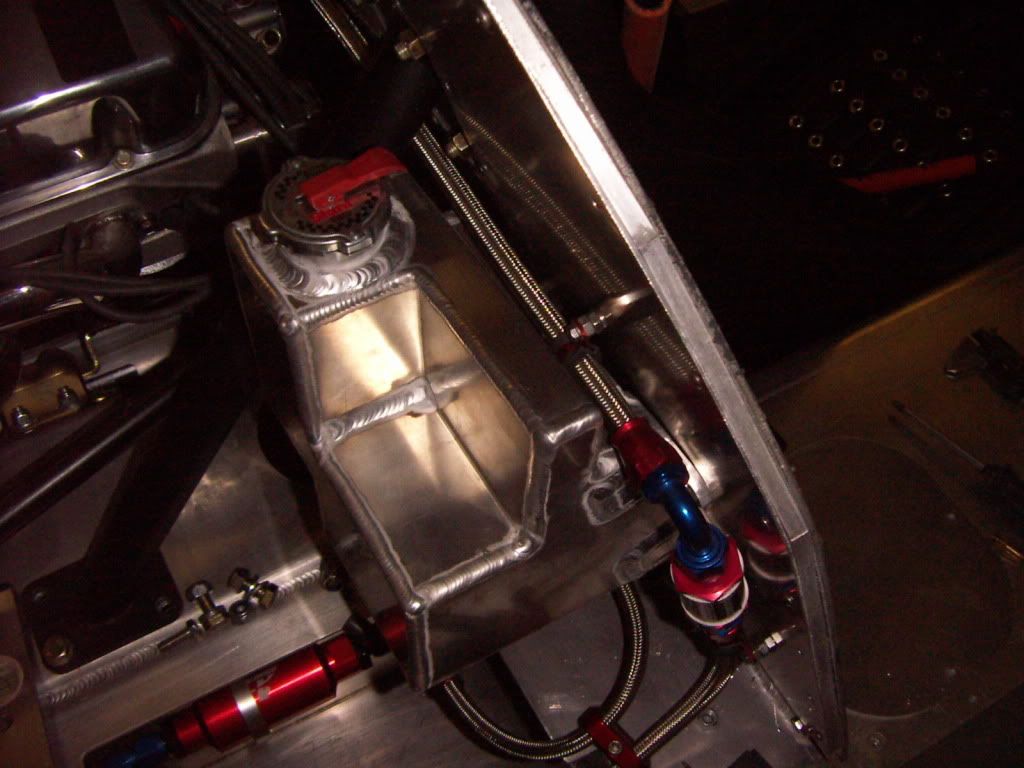

I calculate a total water volume of around 14 liter ( 3,6 gls) ( including the 2 liters in the expansion tank). If one assume a expansion rate of 8 % ( which is a lot and i think a save assumption) the 1, liter expansion room should be ok.

Pressure cap will be a 21 PSI Stanton race cap ( I have not yet found one with lower pressure rating and the release lever).

Well that´s the theory, If you specialists out there could confirm or deny that this is correct i would very much appreciate.

Thanks

TOM

took your advice and made it smaller. Not much but about 25 %.

I also set the expansion tank higher.

The bright tape and red line is marking the top of the thermostat housing level. The volume above is app 1,3 liter the volume below this level is 2 liter.

I won´t use a recovery tank so i designed the expansion tank in a way which enable it to fully cover the expansion without overflow.

I calculate a total water volume of around 14 liter ( 3,6 gls) ( including the 2 liters in the expansion tank). If one assume a expansion rate of 8 % ( which is a lot and i think a save assumption) the 1, liter expansion room should be ok.

Pressure cap will be a 21 PSI Stanton race cap ( I have not yet found one with lower pressure rating and the release lever).

Well that´s the theory, If you specialists out there could confirm or deny that this is correct i would very much appreciate.

Thanks

TOM