I hooked up my heater the same way you did and got zero flow through it. The radiator does not present enough resistance to flow to create a driving head for the heater. I had to add a pump dedicated to the heater circuit.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Toms RCR 40 Trackracer

- Thread starter EGLITOM

- Start date

- Status

- Not open for further replies.

I used a supercharger intercooler pump off a Mustang Cobra or Ford Lightning. They cost about $100 and are available all over ebay. They are not available at most discount auto stores. It works very well. Here is a link for you:

lightning intercooler pump, buy and sell Parts Accessories on eBay Motors

lightning intercooler pump, buy and sell Parts Accessories on eBay Motors

Tom:

Regarding the heater hook up. My experience: it works, but not the best. Until the engine thermostat opens not much hot coolant will flow. Once it opens up, we get some heat. There is a lot of coolant in the GT and it takes a bit of time for it to reach operating temp. Running one heater hose directly from the water pump / engine would be better. But then again, how often do we drive our GTs in really cold weather? Temps in the 30s, 40s and 50s F it is adequate. Not great, but adequate.

The main advantage to this approach is simplicity. One less tube through the center spine. One less long tube where leaks could start. One less hose to clutter up the already crowded front of the engine. I like simple.

Regarding the heater hook up. My experience: it works, but not the best. Until the engine thermostat opens not much hot coolant will flow. Once it opens up, we get some heat. There is a lot of coolant in the GT and it takes a bit of time for it to reach operating temp. Running one heater hose directly from the water pump / engine would be better. But then again, how often do we drive our GTs in really cold weather? Temps in the 30s, 40s and 50s F it is adequate. Not great, but adequate.

The main advantage to this approach is simplicity. One less tube through the center spine. One less long tube where leaks could start. One less hose to clutter up the already crowded front of the engine. I like simple.

FRONTFRAME / RADIATOR / AC CONDENSOR /

Got my originalstyle front frame and related parts back from powder coating.

Installed the frame, the adapted original RCR bottom plate and the alu side walls inclusive the originalstyle brake ducts.

The sidewalls and the brakeducts where riveted on the main frame.

THe satin black powder coat is swallowing the flash, so pics are a bit on the dark side.

Also installed my Radiator, A/C condensor and A/C lines.

Lines where powdercoated in gloss black and so are not very visible.

radiator, cooling lines and adjustable fan thermosthat installed as well.

The radiator and the condensor are all mounted on foam pad stripes and or elastic mounting elements.

Front swaybar bar installed as well.

TOM

AWH: 705 h

Got my originalstyle front frame and related parts back from powder coating.

Installed the frame, the adapted original RCR bottom plate and the alu side walls inclusive the originalstyle brake ducts.

The sidewalls and the brakeducts where riveted on the main frame.

THe satin black powder coat is swallowing the flash, so pics are a bit on the dark side.

Also installed my Radiator, A/C condensor and A/C lines.

Lines where powdercoated in gloss black and so are not very visible.

radiator, cooling lines and adjustable fan thermosthat installed as well.

The radiator and the condensor are all mounted on foam pad stripes and or elastic mounting elements.

Front swaybar bar installed as well.

TOM

AWH: 705 h

Last edited:

Hi Brisc

The front frame is steel, the panelling is alu ( like on the originals) check here

http://www.gt40s.com/forum/gt40-build-logs/24525-toms-rcr-40-trackracer-15.html#post268424

THe rollcage is DOM material, but you need to ask Fran for the exact spec

TOM

The front frame is steel, the panelling is alu ( like on the originals) check here

http://www.gt40s.com/forum/gt40-build-logs/24525-toms-rcr-40-trackracer-15.html#post268424

THe rollcage is DOM material, but you need to ask Fran for the exact spec

TOM

They are using 6061-T6 for the chassis and then they make the front end and the roll bars out of mild steel? These are all tubes and the only thing you'd need to do is to increase the wall thicknesses a bit when changing from steel to aluminium to get significant weight savings. The external diameters could all stay the same.

As long as it's not a robe and as long as it doesn't need to be hardened, there's no reason why you would use steel these days - or does somebody disagree with me on that?

As long as it's not a robe and as long as it doesn't need to be hardened, there's no reason why you would use steel these days - or does somebody disagree with me on that?

Brisc,

if you would read the link i posted ( especially for you), you would see that this rear and front frame is my own construction.

They = RCR are not using any steelframe at all. The original front and rear body supporting structure is made by the factory out of 6061 T6 as well and is a waterjet cutted CNC bent panel construction.

RCR original front structure:

RCR original rear structure:

I decided for my self to built a rear and front structure out of tubular steel to match the ones you can see on original cars. To make them looking correct i also decided to use the same diameter Tubes and the same material.

TOM

if you would read the link i posted ( especially for you), you would see that this rear and front frame is my own construction.

They = RCR are not using any steelframe at all. The original front and rear body supporting structure is made by the factory out of 6061 T6 as well and is a waterjet cutted CNC bent panel construction.

RCR original front structure:

RCR original rear structure:

I decided for my self to built a rear and front structure out of tubular steel to match the ones you can see on original cars. To make them looking correct i also decided to use the same diameter Tubes and the same material.

TOM

That makes sense now! I don't really get the point of the steel frame though, don't take it to heart mate, it looks awesome and sure you put heaps of effort into it, but where's the point in making something look original when its not original? But I think many of us would disagree with me on that  . The aluminium frames are better than the steel ones, just as the aluminium monochoque is better than any tubular steel chassis (if designed right). For my personal taste, there're still too many structural components made out of steel on the RCR built (it's still the best chassis you can get from an engineering point of view). That brace behind the seats looks like sort of a built-in roll bar, is that steel?

. The aluminium frames are better than the steel ones, just as the aluminium monochoque is better than any tubular steel chassis (if designed right). For my personal taste, there're still too many structural components made out of steel on the RCR built (it's still the best chassis you can get from an engineering point of view). That brace behind the seats looks like sort of a built-in roll bar, is that steel?

These mounting brackets on the chassis where the A-arms and the suspension attach, are there any stiffeners welded onto the backside?

Thanks a lot Tom,

(your built is amazing, really nice)

These mounting brackets on the chassis where the A-arms and the suspension attach, are there any stiffeners welded onto the backside?

Thanks a lot Tom,

(your built is amazing, really nice)

I really LOVE to follow your works in progress , Tom !

That makes sense now! I don't really get the point of the steel frame though, don't take it to heart mate, it looks awesome and sure you put heaps of effort into it, but where's the point in making something look original when its not original? But I think many of us would disagree with me on that. The aluminium frames are better than the steel ones, just as the aluminium monochoque is better than any tubular steel chassis (if designed right). For my personal taste, there're still too many structural components made out of steel on the RCR built (it's still the best chassis you can get from an engineering point of view). That brace behind the seats looks like sort of a built-in roll bar, is that steel?

These mounting brackets on the chassis where the A-arms and the suspension attach, are there any stiffeners welded onto the backside?

Thanks a lot Tom,

(your built is amazing, really nice)

No offense done. The point is just that i try to describe as detailed as possible, one just needs to take the time to read it.

Don´t understand your point regarding to much steel in structural components. All the structural components are in aluminium. THe rollbar is not built in, it is added to the chassis. THe chassis itself is tested and approved in Australia without the rollbar. The 6 point roll bar is an option which i have chosen. I personally realy on steel here. You could make it in alu, but depending on your race organisation it can be difficult to get it accepted.

Yes there is a brace behind the mounting point of the upper front control arms. The bottomplate of the spare wheel recess is going all the way to the sidewalls of the chassis and meet it there almost exactly in the center of the mounting brackets.

TOM

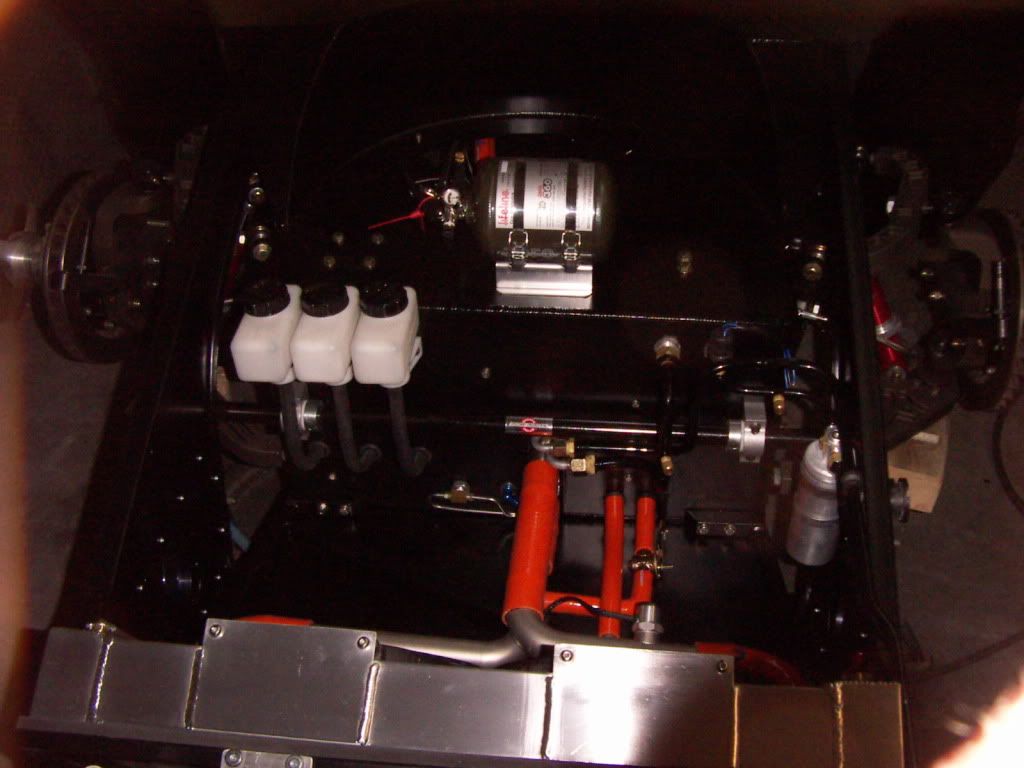

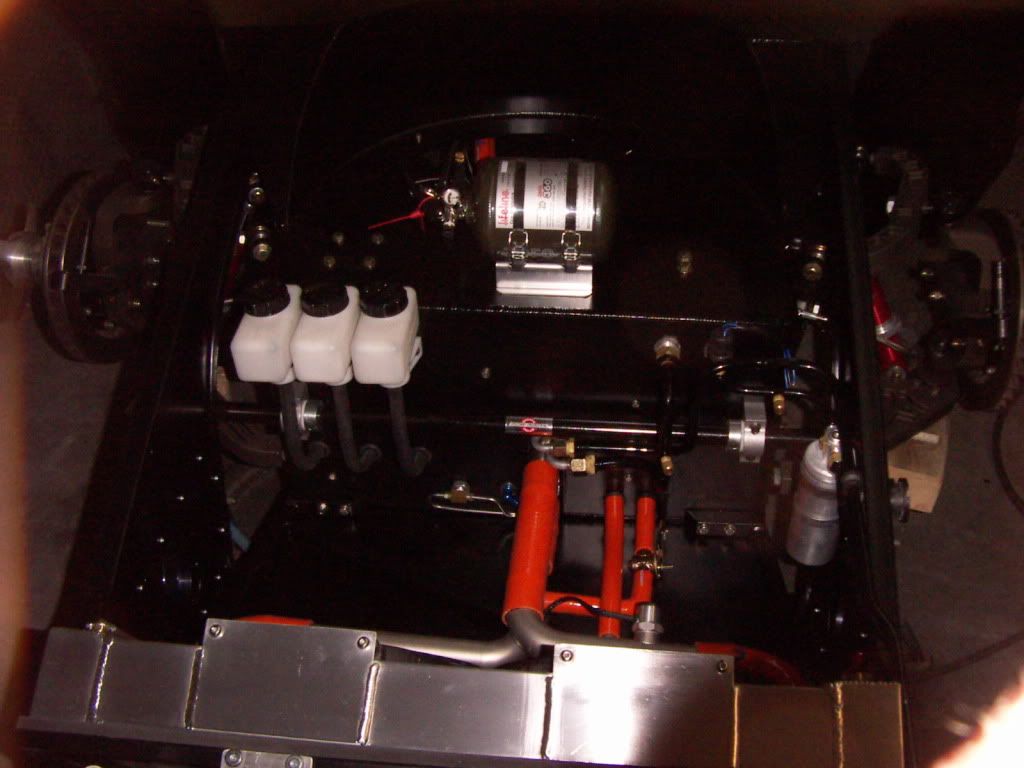

After getting back my firewall panels from the powdercoater i started to do the final assembly of it. As mentioned in an earlier post i´m added an additional second aluminium panel and sandwiched the insulation inbetween.

Original RCR Firewall with Dynamate and spacer bars applied

my second panel with Dynaliner applied

as the rear window is now also sandwiched inbetween. i applied foam pad stripe ot get it mounted in a flexible way.

The perimeters where than sealed with liquid PU sealing.

Here is the final result mounted on the car. I like this raw look. The bolts used to connect both panels look like rivets of you viewed from 2m away.

I also prepared the final installation of my fuel system. Next step will be to install the fuel pickups. To do so if first flushed my tanks to get rid of most of the debris and dirt in there from the build process. I used a drill driven pump to suck it out and flushed it from the front ( which was lifted) with hot water.

TOM

AWH: 718h

Original RCR Firewall with Dynamate and spacer bars applied

my second panel with Dynaliner applied

as the rear window is now also sandwiched inbetween. i applied foam pad stripe ot get it mounted in a flexible way.

The perimeters where than sealed with liquid PU sealing.

Here is the final result mounted on the car. I like this raw look. The bolts used to connect both panels look like rivets of you viewed from 2m away.

I also prepared the final installation of my fuel system. Next step will be to install the fuel pickups. To do so if first flushed my tanks to get rid of most of the debris and dirt in there from the build process. I used a drill driven pump to suck it out and flushed it from the front ( which was lifted) with hot water.

TOM

AWH: 718h

Tom

What is the purpose of the second (sandwich) panel on the firewall? Is it only to conceal the insulation? Looks great.

Eric

Thats one function, the other is to have a base for mounting all the elements towards the engine compartment without the need and splattered look of bolt through installations. I do use rivnuts on the backside panel.

TOM

- Status

- Not open for further replies.