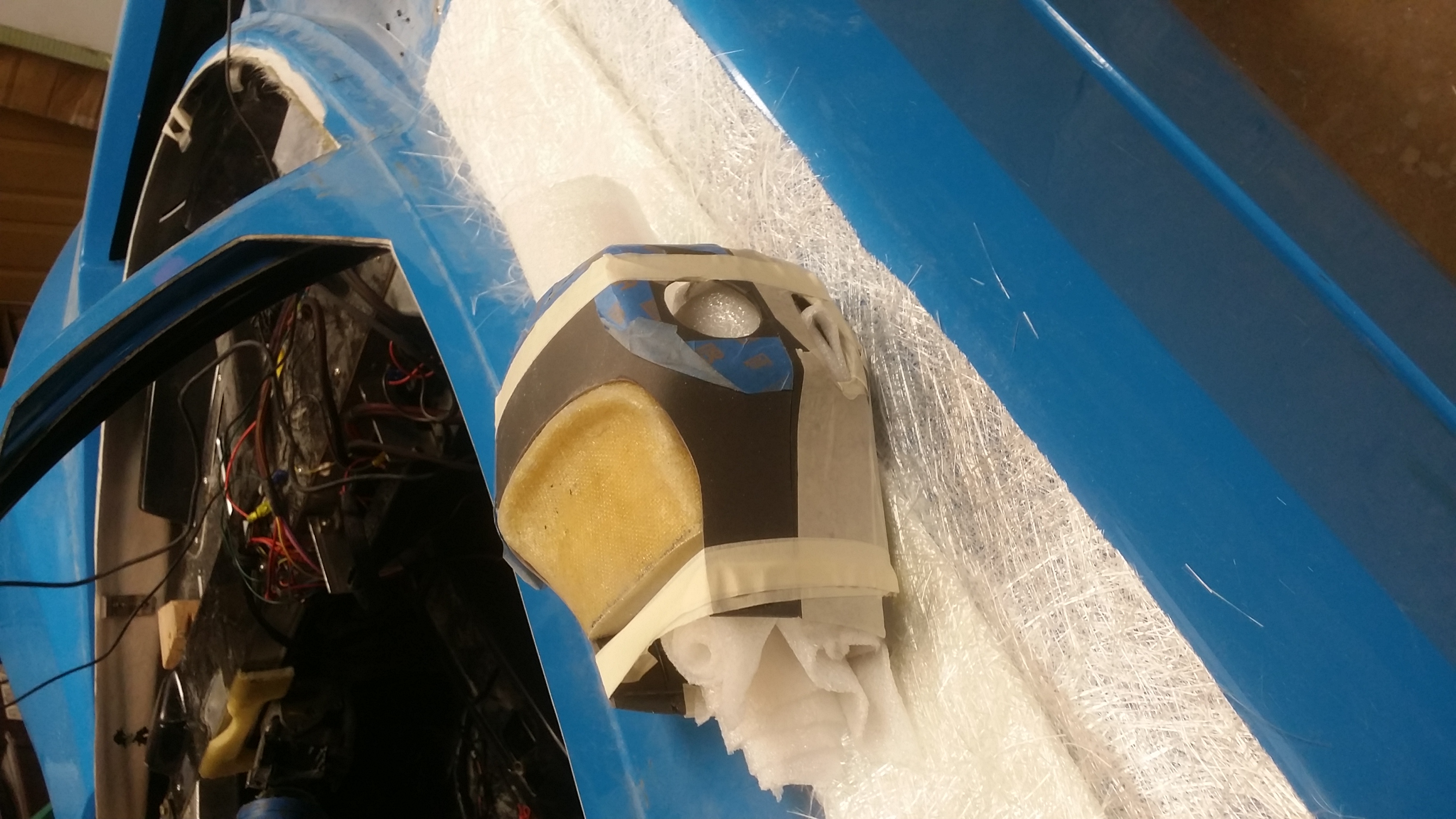

Troy was gracious enough to build me an engine mount, but it didn't fit. His 1UZFE is from an LS400, so I guess that means mine is from an SC400. Either way, the engine mount had to be redone. I designed and fabricated it myself. My first engine mount. I didn't weld it, I had to farm that out

Before posting this, I figured I better run out and see if it fits. I DID design this by eye with a measuring tape. It does in fact fit. One of the holes is off center and too close to the edge but that can be fixed.

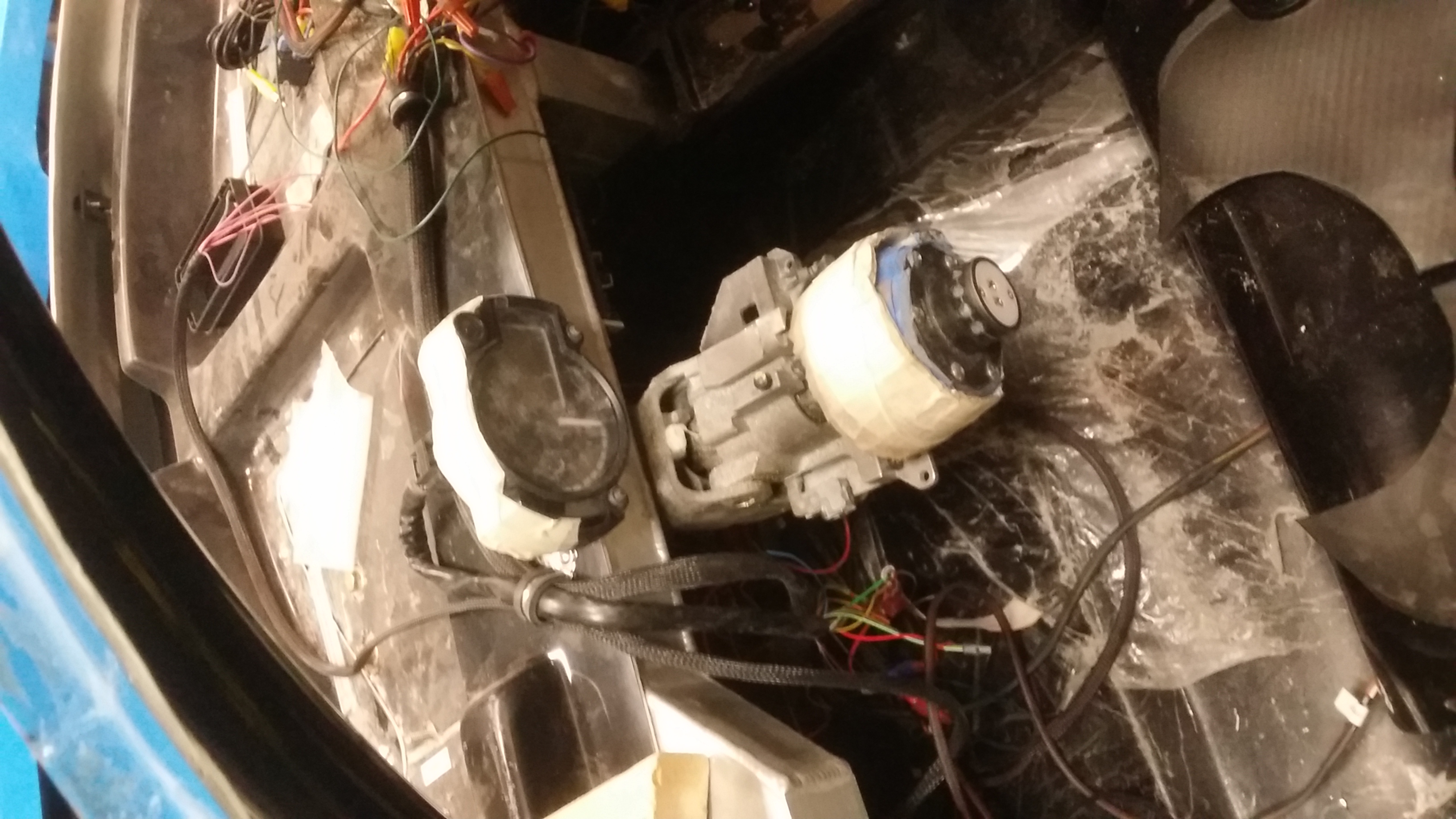

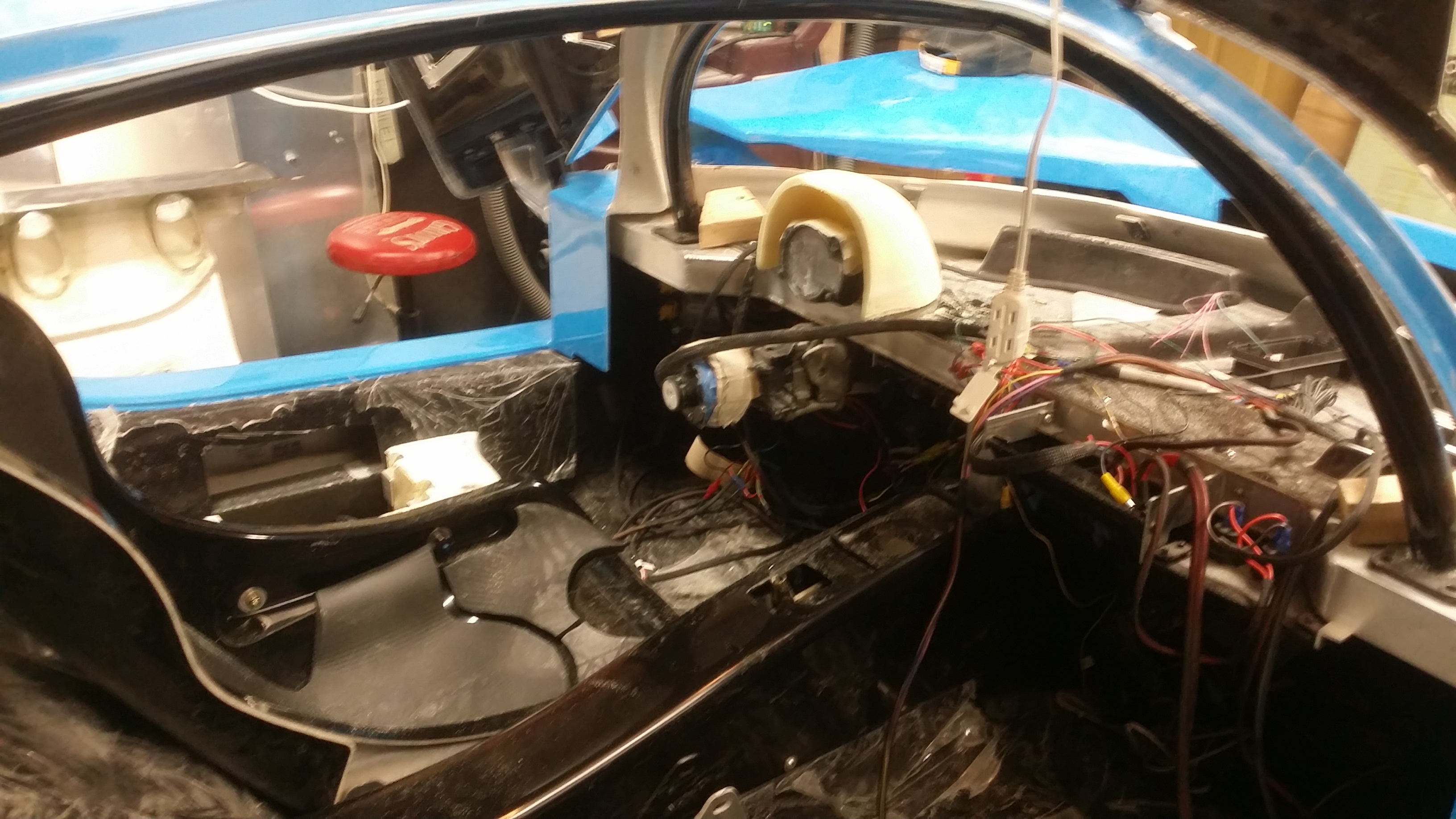

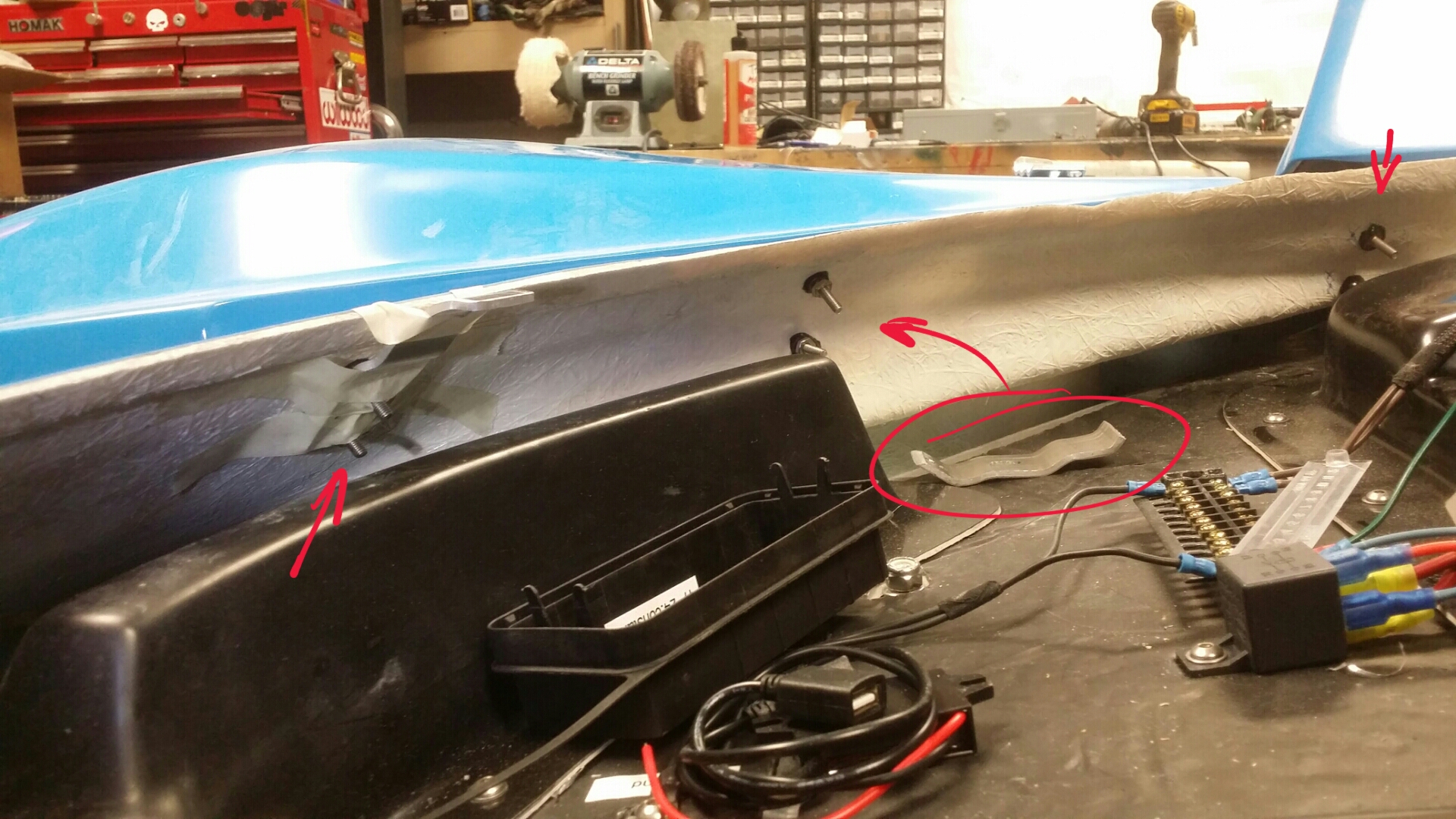

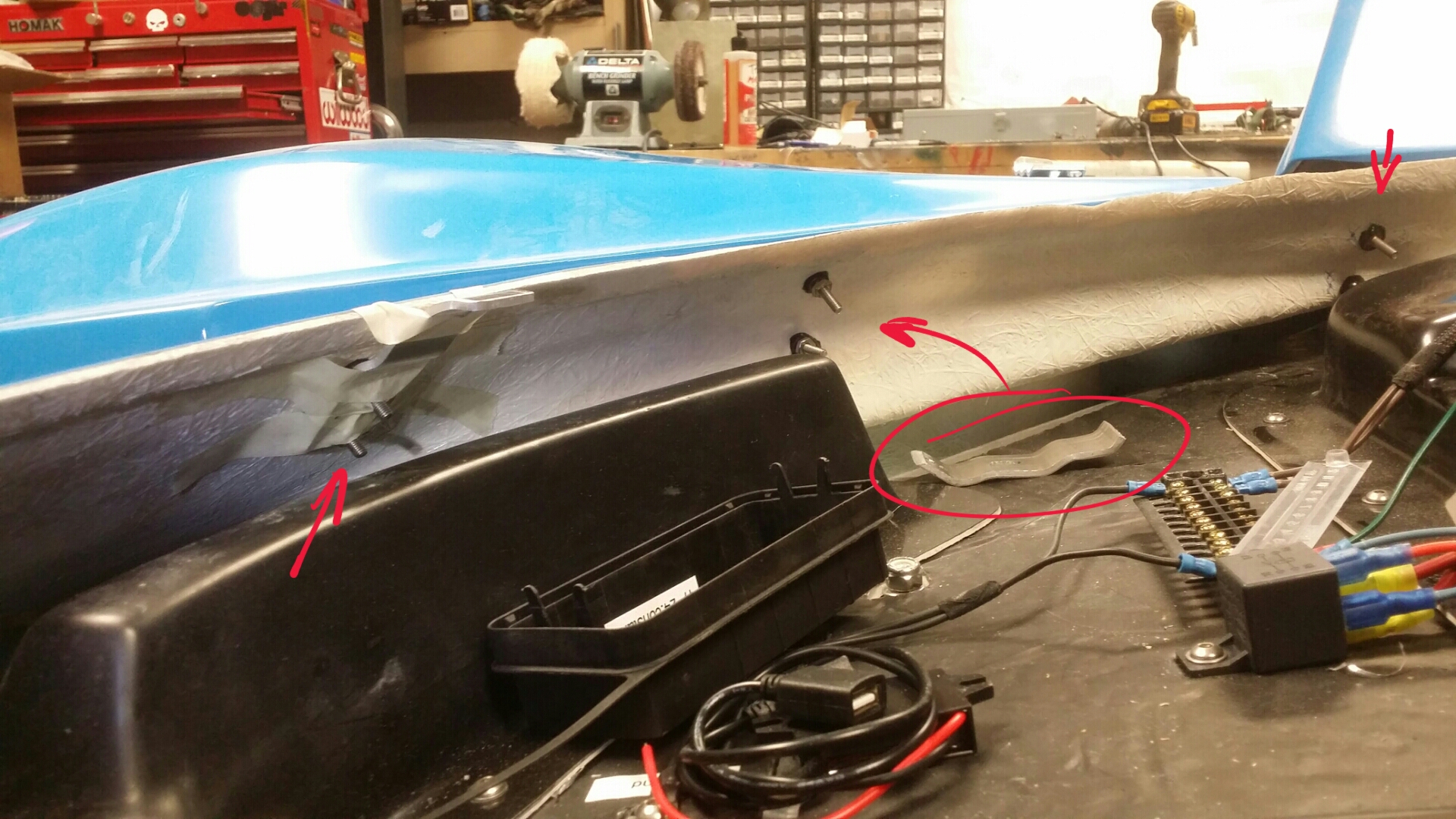

I also got my dash supports installed. I bonded 10-32 screws to the windshield opening. The screw heads were sanded smooth to look like a miniature weld stud. I also ground flats on both sides of the head so it had less tendency to rotate under torque. The brackets are slotted so I can adjust each point so I can fine tune the dash location. I knew there was no way I was going to get this just right on my first try if I glued the brackets themselves to the opening. So I designed in a little adjustability. I plan on putting the hi temp silicone strips (which is from McMaster and was purchased to use on the fuel tank installation) on the bracket ends to keep the dash from rattling.

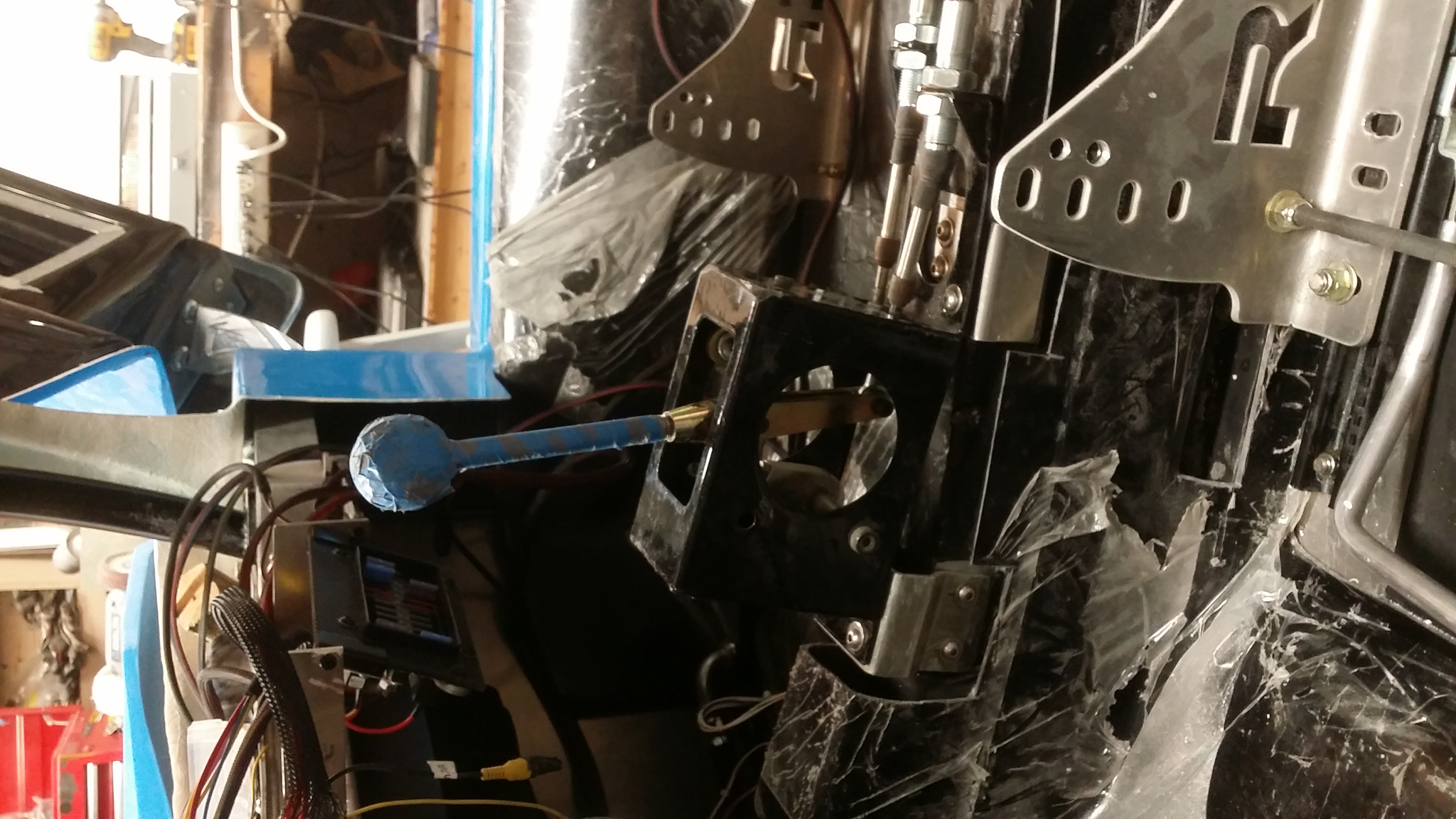

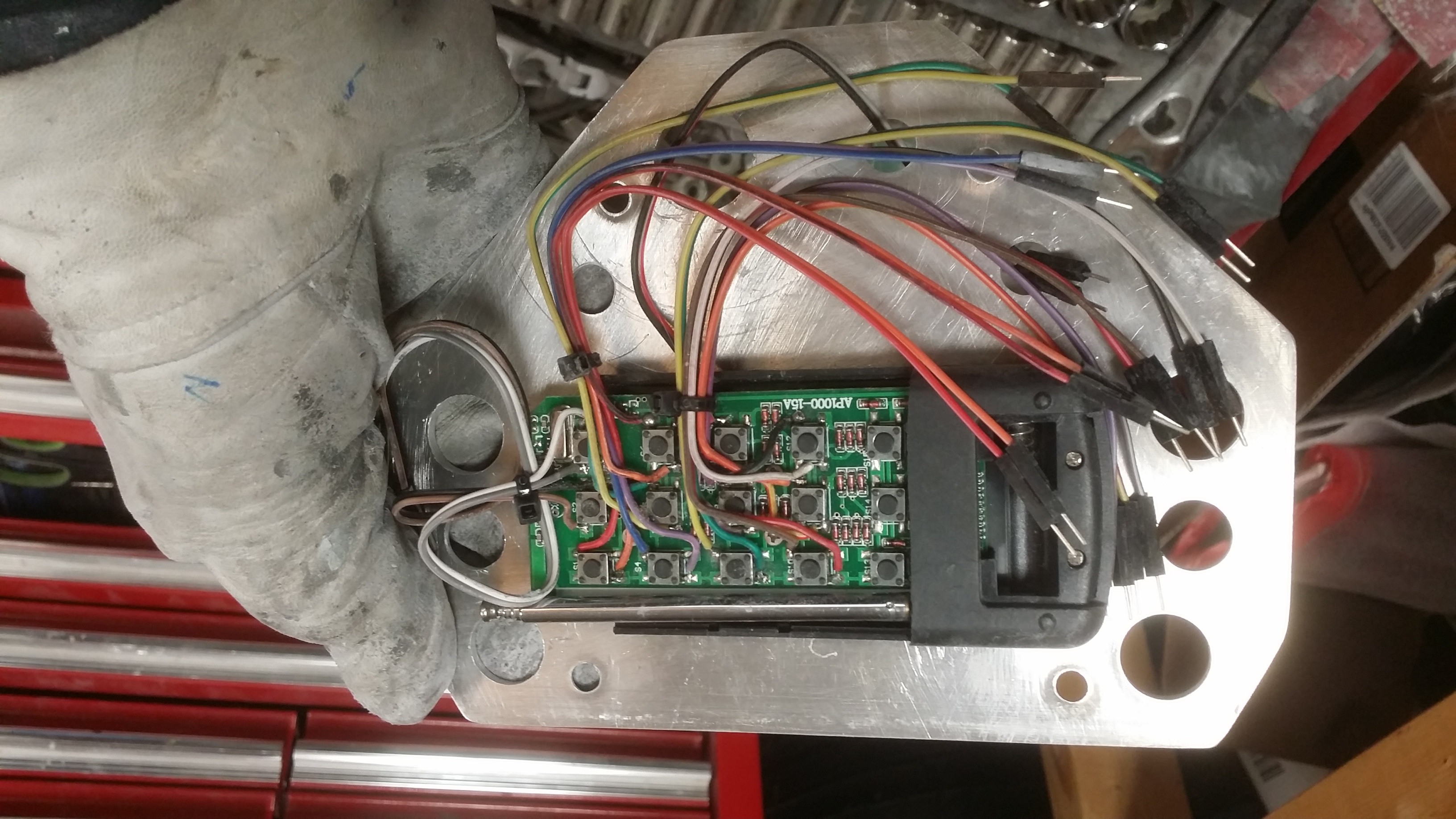

I also got the center console panel made and the monitor mounted in it:

Before posting this, I figured I better run out and see if it fits. I DID design this by eye with a measuring tape. It does in fact fit. One of the holes is off center and too close to the edge but that can be fixed.

I also got my dash supports installed. I bonded 10-32 screws to the windshield opening. The screw heads were sanded smooth to look like a miniature weld stud. I also ground flats on both sides of the head so it had less tendency to rotate under torque. The brackets are slotted so I can adjust each point so I can fine tune the dash location. I knew there was no way I was going to get this just right on my first try if I glued the brackets themselves to the opening. So I designed in a little adjustability. I plan on putting the hi temp silicone strips (which is from McMaster and was purchased to use on the fuel tank installation) on the bracket ends to keep the dash from rattling.

I also got the center console panel made and the monitor mounted in it: