Brett James-McCall

Moderator

I've got one of my team travelling to the US, so he has a task

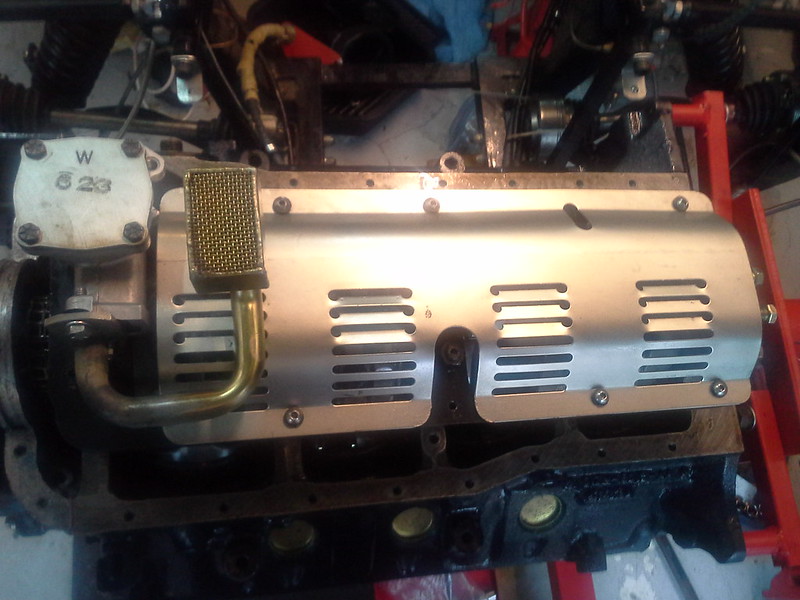

I knew someone would pick up on thatArrows are from the balancer, it was him marking up to make sure that he had pistons and rods the right way round. Before you ask. To make sure, I makred a divided box up with numbered areas and Front, back, Damper, Flywheel to make sure they understood where it all went. Yes, my left is some peoples' right in this case. It was just the way I did it at the time.

Brett

On SBF engines, I use liquid teflon thread sealant on all the bolts that go into the block with the exception of motor mount and bellhousing bolts..