Hello Fred

As usual very neat progress

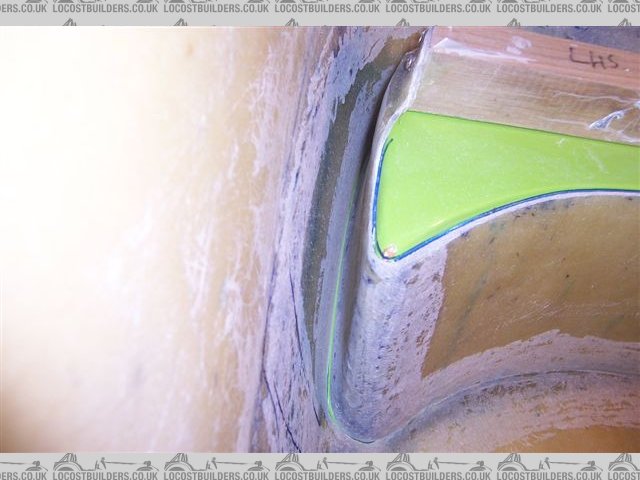

concerning Gelcoat ; I do not think you will have any issue watching all parts you did by before and anyway yes it's very easyy to correct small place if someday you got a bad spot ( gelcoat is very easy to sand and polisch but you need to do correction with same batch number to get the same white color

And if you intend to paint your bodywork you do not have to worry at all ?

Keep on your progress we are following you day after day Mate !

As usual very neat progress

concerning Gelcoat ; I do not think you will have any issue watching all parts you did by before and anyway yes it's very easyy to correct small place if someday you got a bad spot ( gelcoat is very easy to sand and polisch but you need to do correction with same batch number to get the same white color

And if you intend to paint your bodywork you do not have to worry at all ?

Keep on your progress we are following you day after day Mate !