Thanks for making that clear Paul. The guys at InnoV8 are also very helpful and have assisted me with some great engine tips. Thanks guys.

Transaxle and Engine Coolers (I would appreciate some advice)

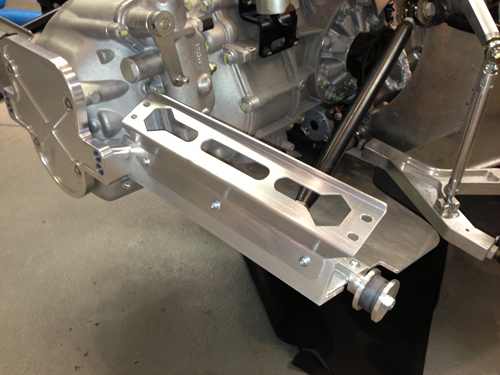

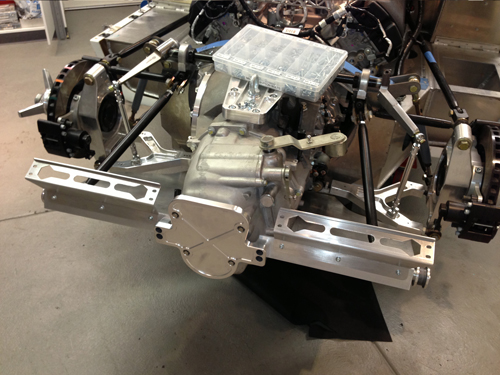

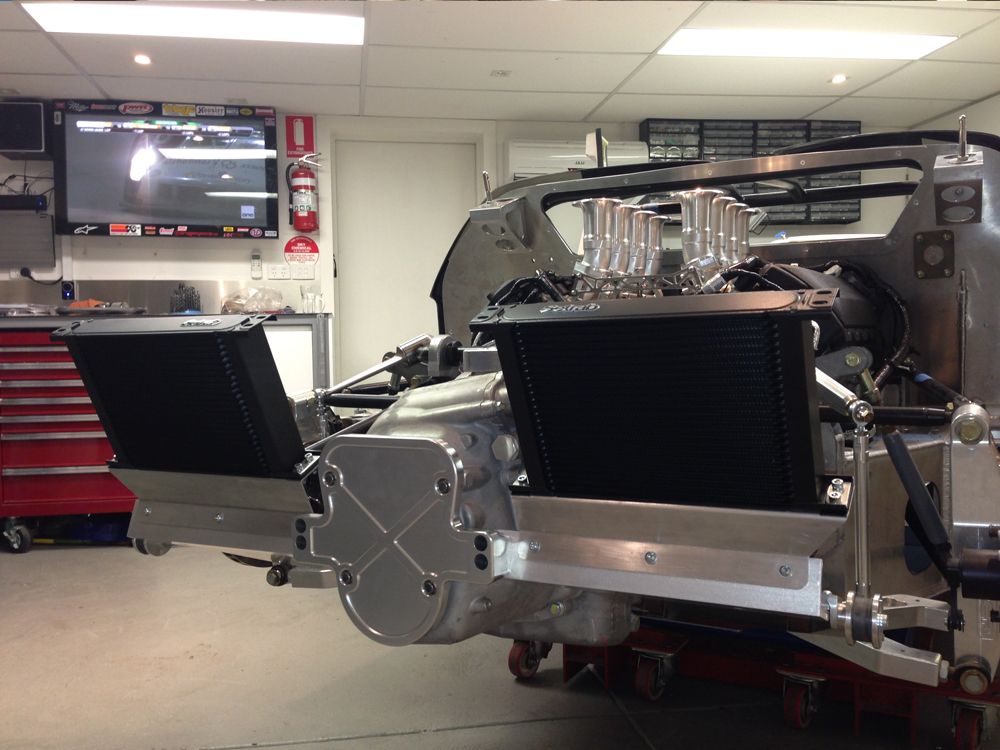

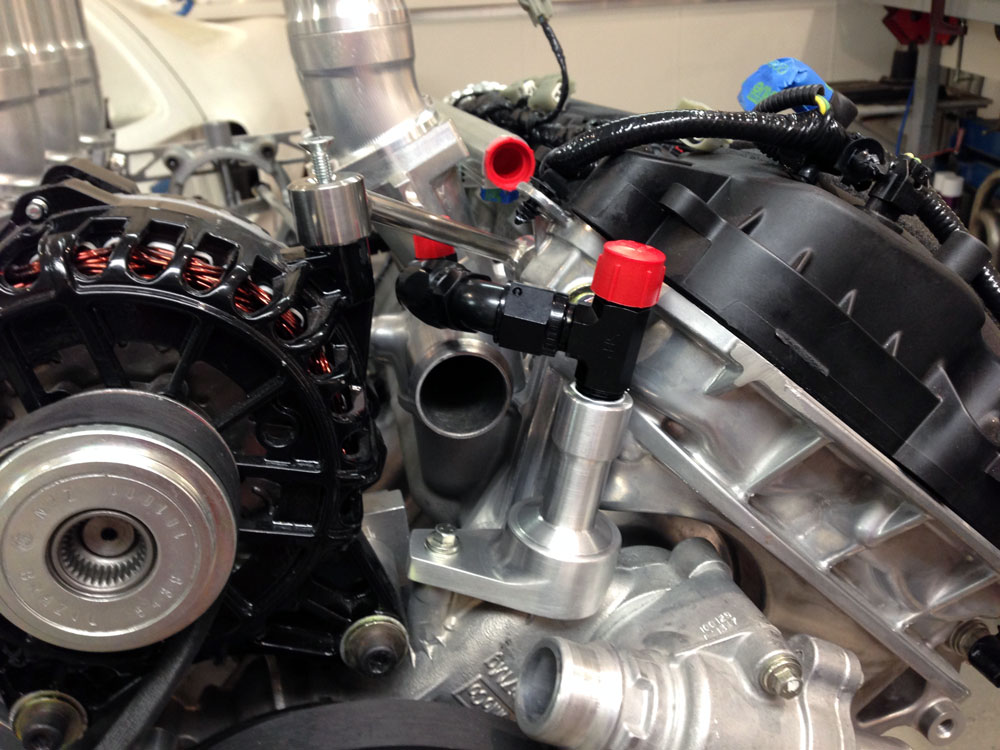

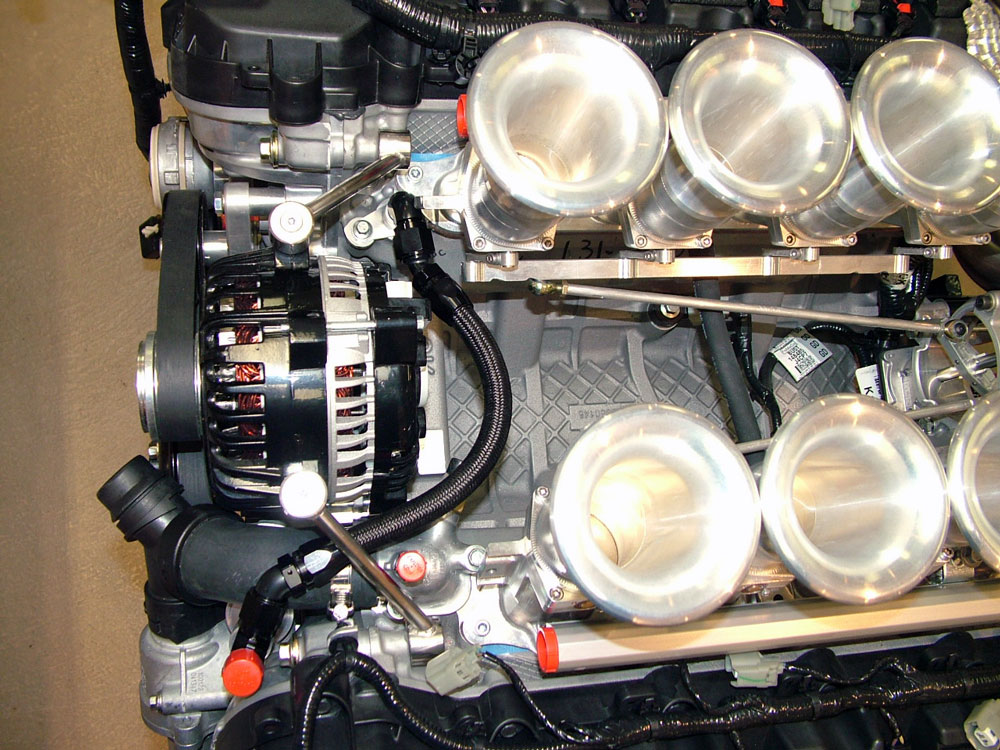

I decided to fit air to oil coolers, I was looking at a Laminova water to oil cooler but was worried about routing hoses to the front of the engine. I decided to fit air to oil coolers at the rear for mostly visual reasons. I wanted to see radiators through the back of the car! I do not plan on fitting any alloy covers on the rear clip. Brackets were made out of 2.5mm aluminium to mount the coolers.

I also decided to go with the same size coolers one of which is over sized for the transaxle. This was only done for symmetry when looking at the rear of the car. A pretty bad reason but what the hell!

Secondary cooler stabilisation will follow. Orientation of the coolers was checked with Setrab and they replied in detail on why it is not an issue at all. Great service from them on this, very helpful.

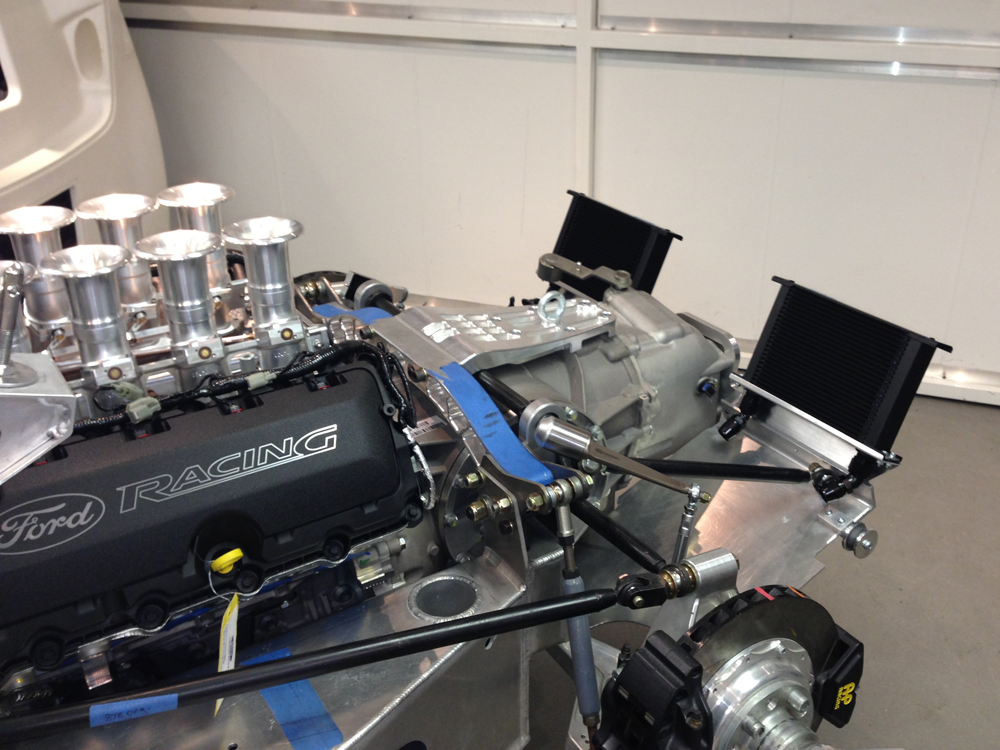

I have a Mocal thermostat for the transaxle (thanks for the tip Fran) which will help warm up the oil so that side is fine. Transaxle lines are AN-10 and engine in AN-12.

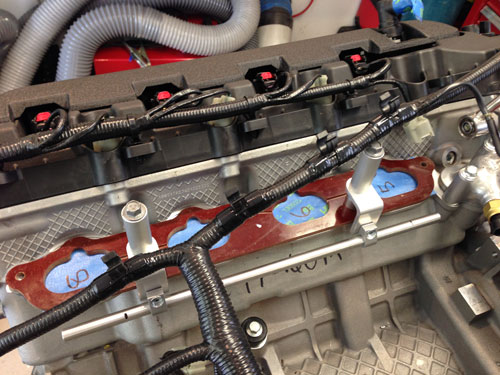

I also have a thermostat for the engine side but I do not know if I should use it?

Up Sides of fitting an engine thermostat

1) Faster warm up

2) I don't have a spare thermostat!

Down sides

1) Fitting the thermostat and remote oil filter on the rear alloy panel is BLOODY tight. It will be a mess of hose.

2) Creates an oil flow restriction. Even with my upgraded billet oil pump this is a concern as highlighted by Tom.

3) Uses more fittings and therefore more potential leak points.

Any help with this decision would be greatly appreciated.