Hi Jason,

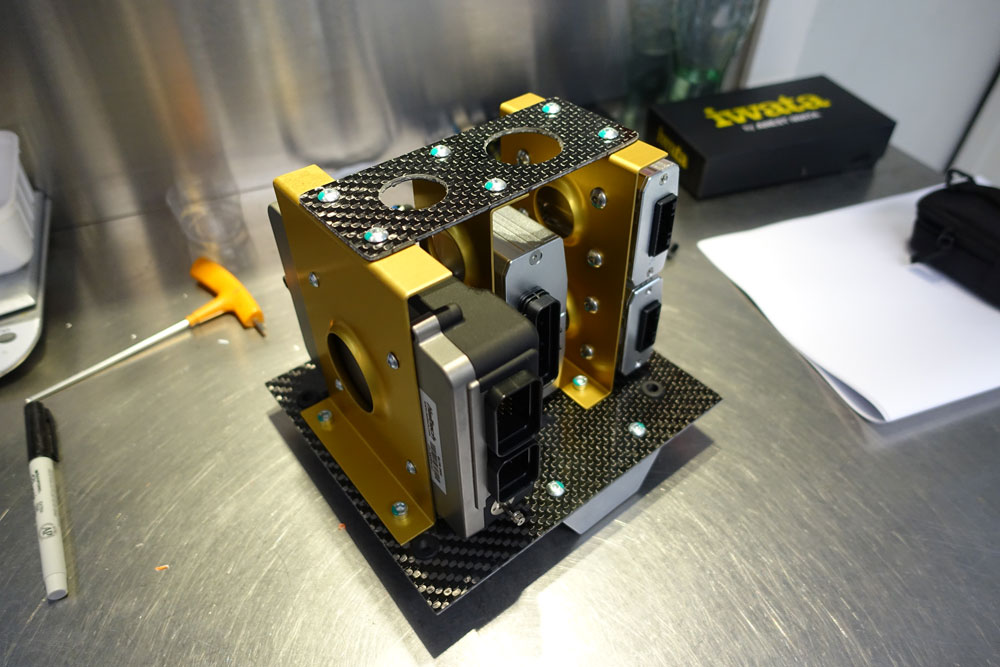

Deep respect. It is built with aerospace precision and beyond.

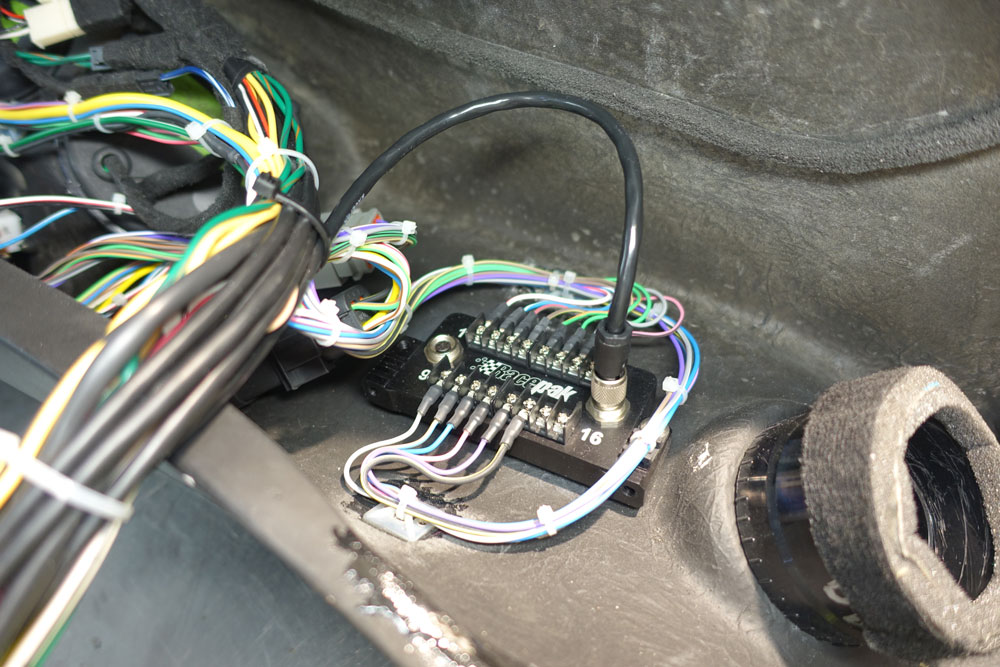

Which type of Deutsch connector and contacts are you using ?

Titanium connector with gold plated contacts ?

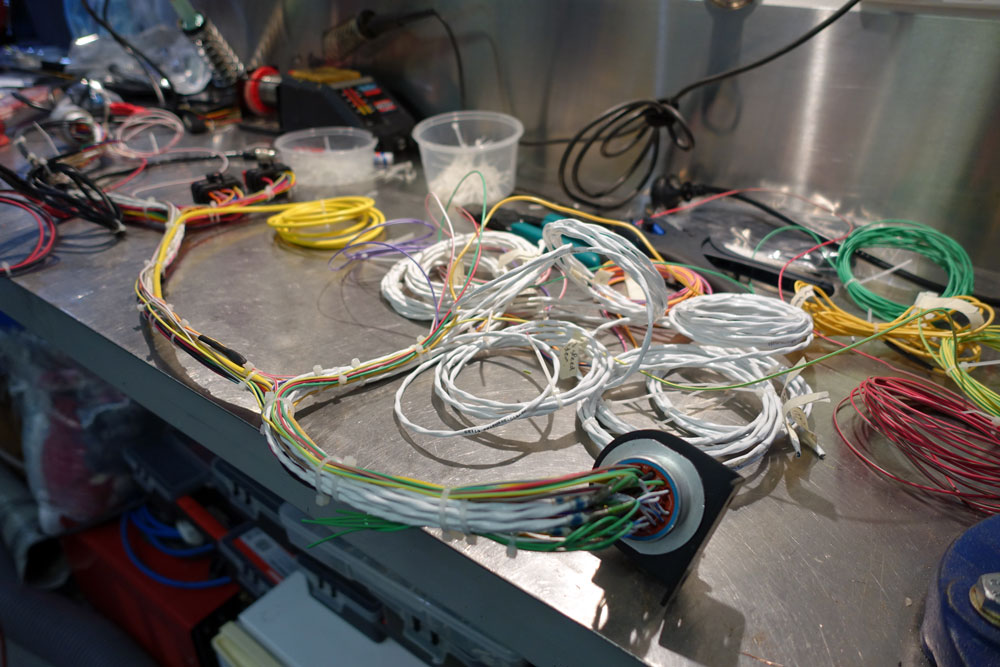

Perhaps you are aware, make sure the receptacle plug is fixed somewhere to the chassis since it is relative heavy and you dont want this to float around. They also have composite connectors on the market in this type but they tend to become brittle at higher temps and after 10 years. The bundle to connector has to be supported for stress relief in case you pull on the cable. We use metal braided socks over the bundle and use bendix clamps to fix the bundle down to the connector. In case you pull on the bundle, the metal braided sock takes the loads and not the crimped wires in the contacts. You also can use viton rubber at the end of the connector in between to seal it down as much as possible. Or use Raychem shrink boots at the end of the connector.

Keep up the good job, you could publish a photo book of your build with all the nice anodished parts , a joy to watch.