Put the Engine Back In for the Final Time?

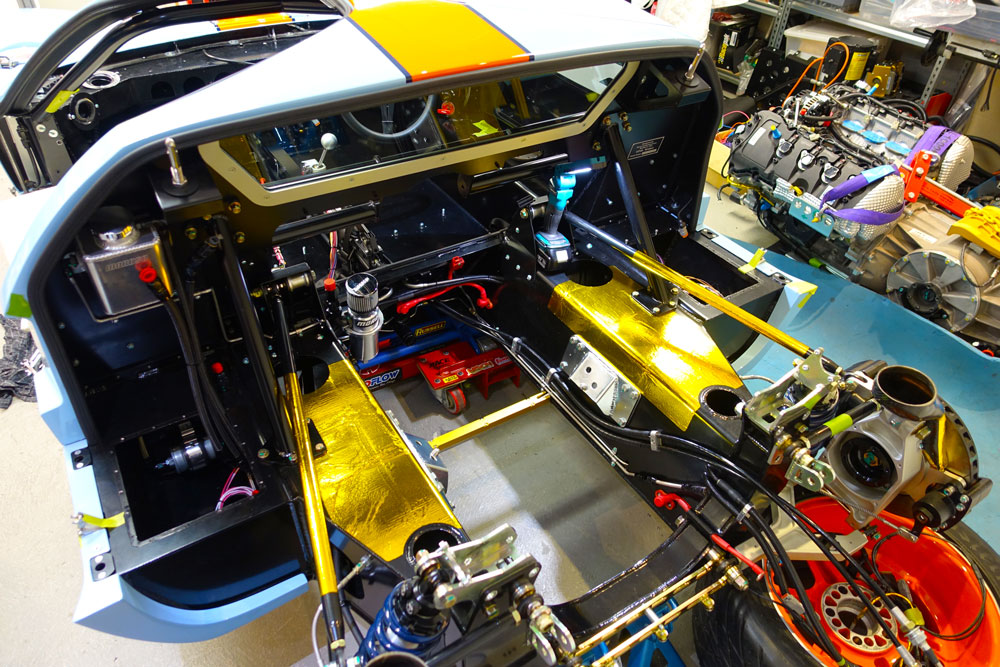

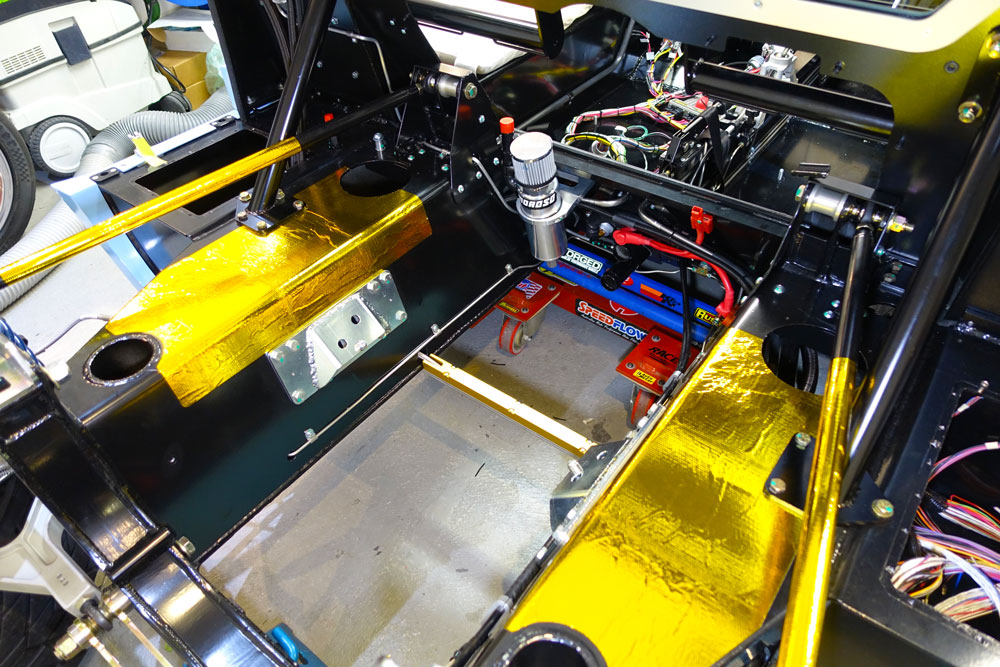

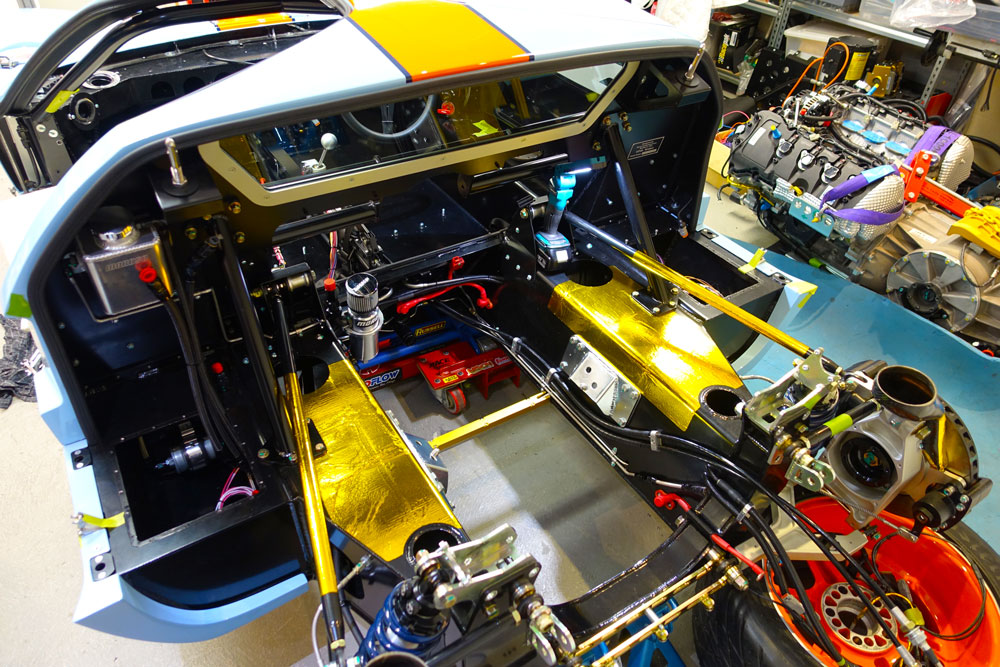

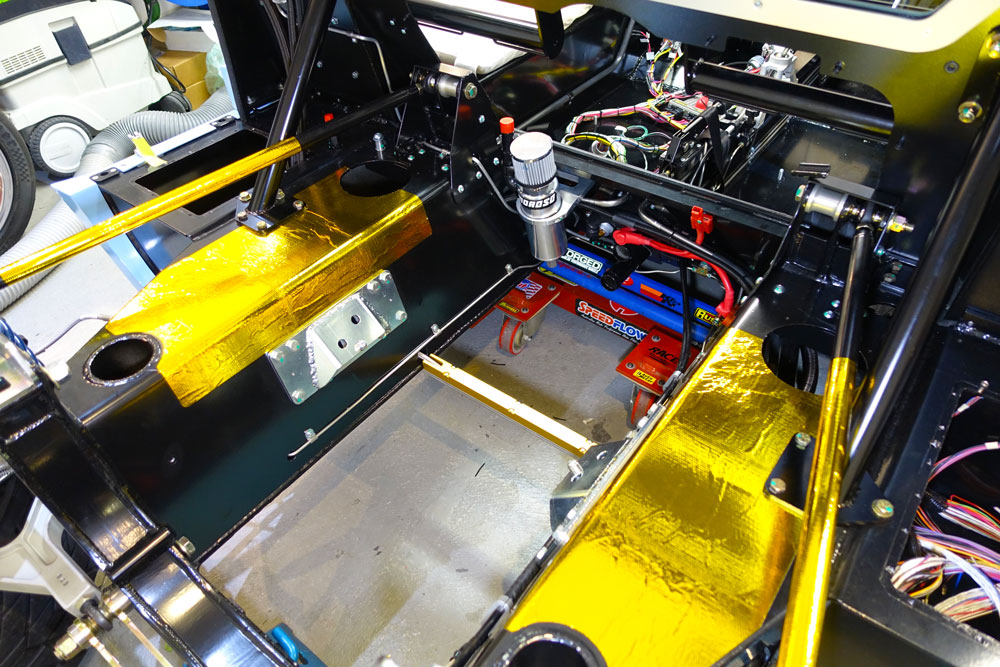

Well a lot of work going on. With the wiring done around the engine it can be installed for hopefully the last time. All parts get their final finishes. Before installation I wanted to try to minimise as much heat into the chassis as possible so I went crazy with DEI gold heat reflective film!

I also did a little work on the radius rod supports.

Then it was time to install the engine and exhaust.

It all went very well. Its a very tight installation but that is the result of a Coyote and Ricardo in an RCR chassis. To get the engine out the headers have to be removed so I hope all is well.

I still have the wiring near in the ECU box to go but all other electrical is done.

Even though the exhaust is ceramic coated on the inside I really wanted to control the radiant heat on the transaxle. O2 sensors are a bit ugly but really needed to tune.

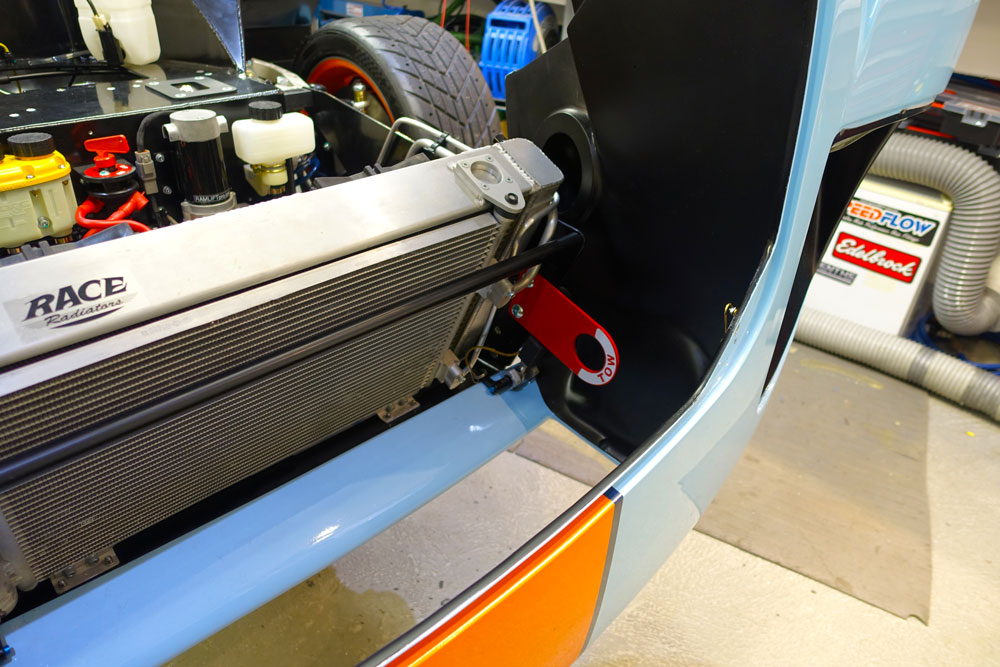

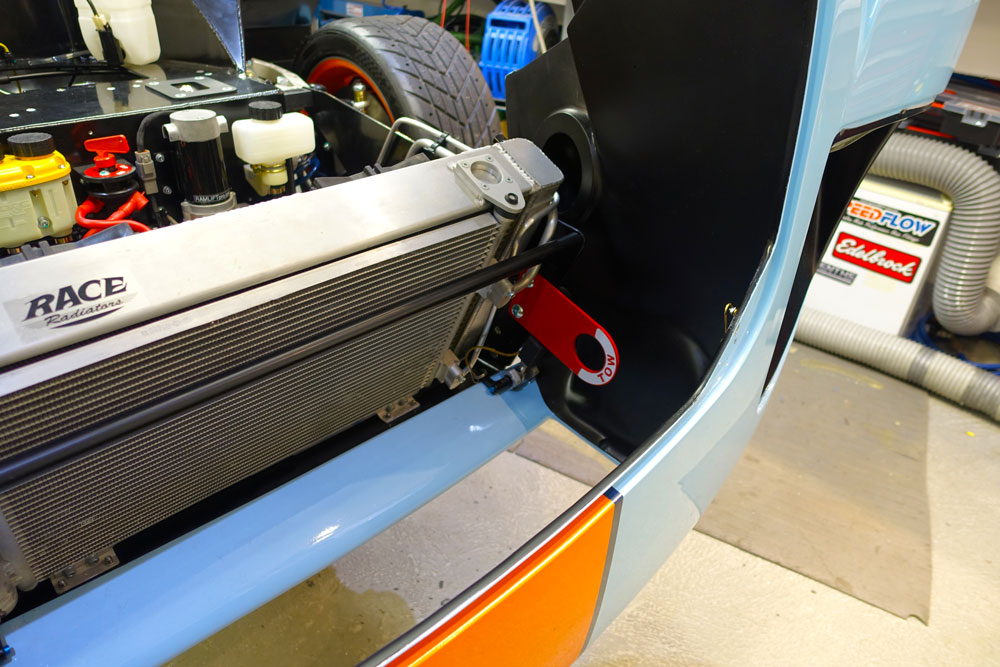

I moved to the front and with the confidence I have with my skills installed a tow hook. It will be needed I'm sure!

Then I thought that with my luck I will wear it out and installed another in the middle!

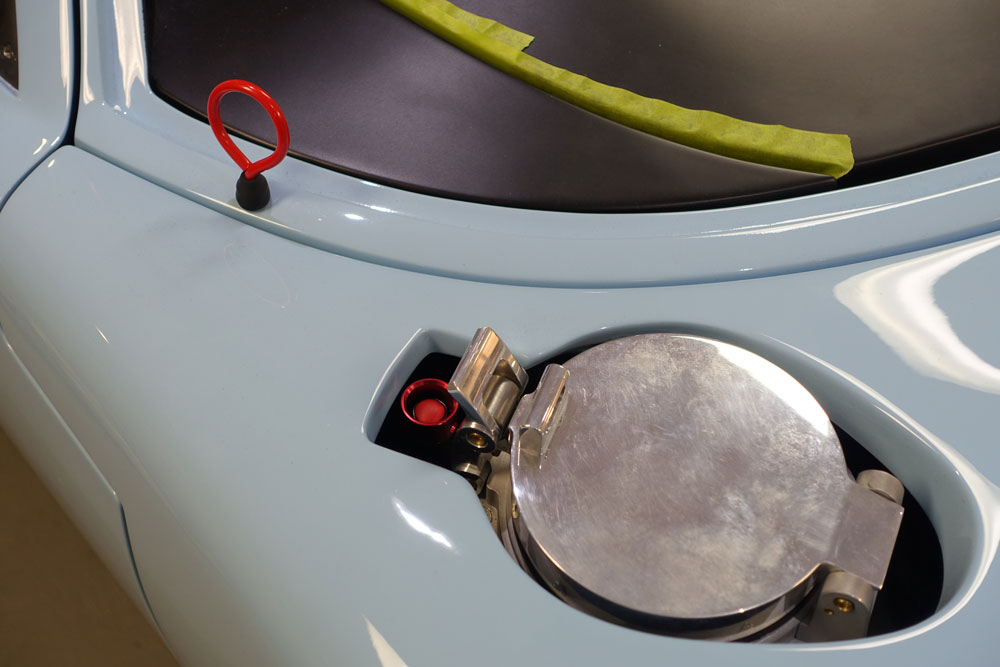

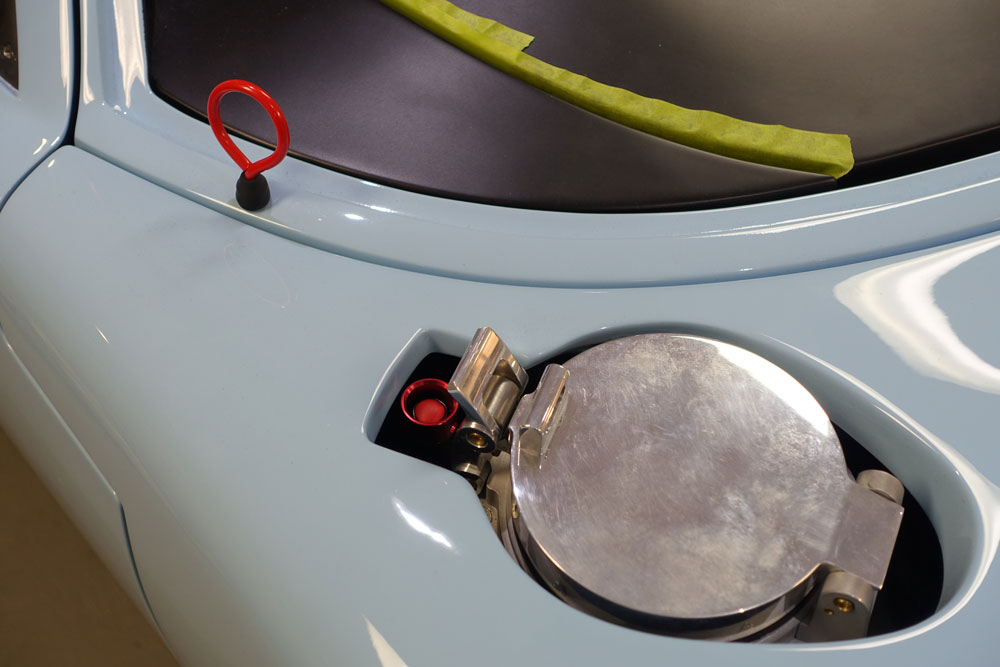

But seriously the one on the left looks cool but the one in the middle is more functional as its in a better position and will not stress the chassis as much as the side one. Also all A/C plumbing is done using as little hose as possible. I then installed the fire extinguisher button (near the filler) and the battery disconnect (near the window).

Brakes and clutch are bled. So now the fun is over, back to wiring up the ECU.

Well a lot of work going on. With the wiring done around the engine it can be installed for hopefully the last time. All parts get their final finishes. Before installation I wanted to try to minimise as much heat into the chassis as possible so I went crazy with DEI gold heat reflective film!

I also did a little work on the radius rod supports.

Then it was time to install the engine and exhaust.

It all went very well. Its a very tight installation but that is the result of a Coyote and Ricardo in an RCR chassis. To get the engine out the headers have to be removed so I hope all is well.

I still have the wiring near in the ECU box to go but all other electrical is done.

Even though the exhaust is ceramic coated on the inside I really wanted to control the radiant heat on the transaxle. O2 sensors are a bit ugly but really needed to tune.

I moved to the front and with the confidence I have with my skills installed a tow hook. It will be needed I'm sure!

Then I thought that with my luck I will wear it out and installed another in the middle!

But seriously the one on the left looks cool but the one in the middle is more functional as its in a better position and will not stress the chassis as much as the side one. Also all A/C plumbing is done using as little hose as possible. I then installed the fire extinguisher button (near the filler) and the battery disconnect (near the window).

Brakes and clutch are bled. So now the fun is over, back to wiring up the ECU.