Brett James-McCall

Moderator

Can I ask how people have installed these. I bought a T piece adaptor, but it seems to interfere. Can people post some photos. Thanks

I have a momentary bypass switch around the fuel pressure cutoff that allows the fuel pumps to work while cranking.

Bill

* * *

Yes, you lose the oil pressure light, but then having the engine suddenly shut off probably already got your attention. Besides, shutting off the engine forces oil pressure to zero anyway, so what is the light really telling you that you don't already know?

* * *

...sender which is connected to the engine by an AN3 stainless braided hose and some adapters.....

THats exactly how i have it done also.

Just used a Dash 4 line going to it

I fabed a stainless T, to which i welded a stainless bracket. THe bracket itself is mounted togehter with the bolt of the engine mount. The bracket is about 4 inches long and bent it will take away the most of vibs. I very much like this location.

TOM

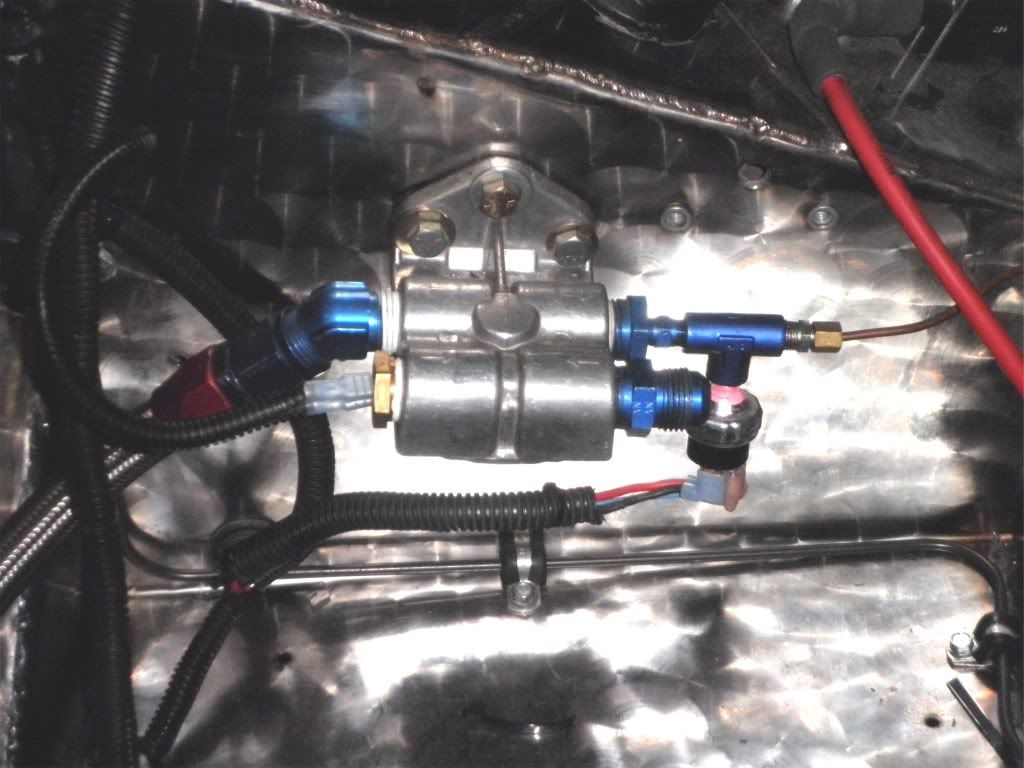

Here's the pic. I was just going to run mine over onto the sill.