You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ed McClements

Supporter

Try Kenny Coleman at EDA. He builds lots of american V8s and often 302 strokers so he may have a good standard crank lying around. He built Mark's engine. He will run your engine and set up on the dyno for about £300.

Engine Data Analysis

Engine Data Analysis "Specialist Engine Building & Tuning"

Cheers

Mike

Hi Mike

Yes - I was planning on heading for EDA after visiting Mark Boyers recently and hearing about the machining & dyno work Kenny did for him. When I take my block over there for machining & cam bearing fitting I'll ask about a crank.

Cheers,

Eddy

Hi Eddy

Looks good, I am waiting for my chassis from SGT which I think is next in line on the "production line", well on the jig anyway

I think I am number 52 or 53

Cheers

Hi Eddie,

You won't be disappointed and I think they are well past those numbers now. I popped by on Tuesday to pick up some parts and it was great to see a business really thriving. Look forward to seeing your build thread.

Best.

Nick D.

Ed McClements

Supporter

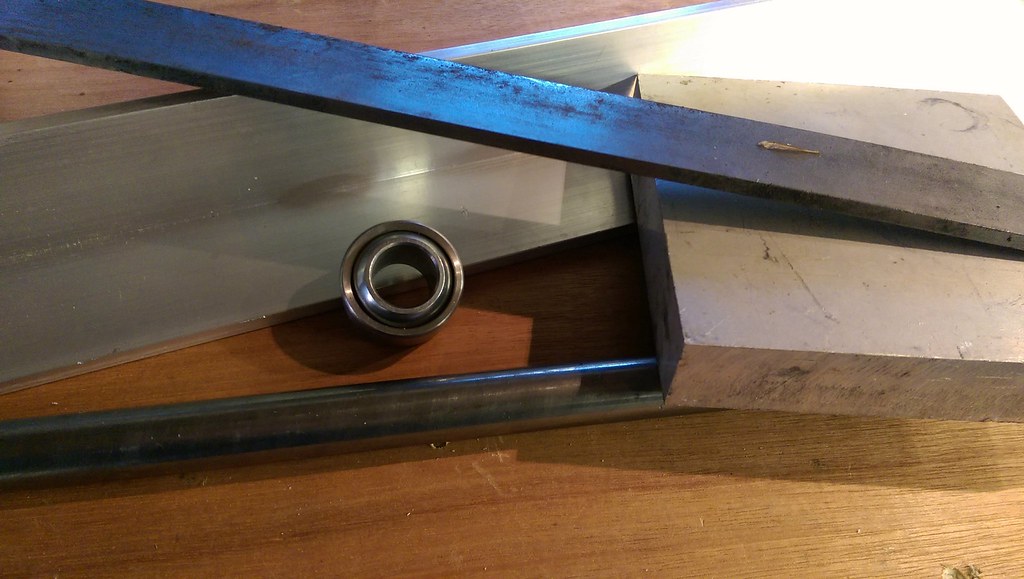

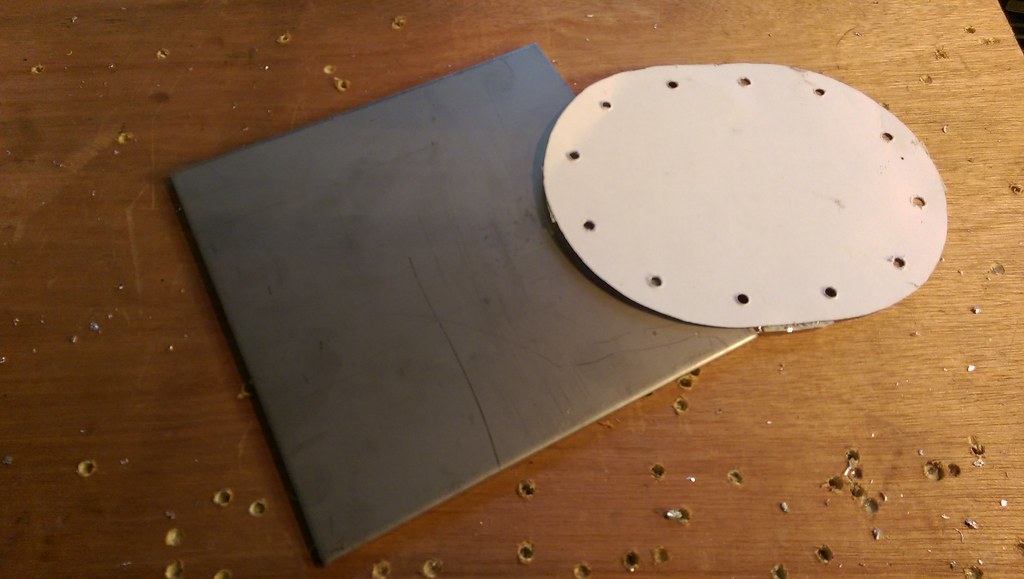

Been busy with the angle grinder. Started with this:-

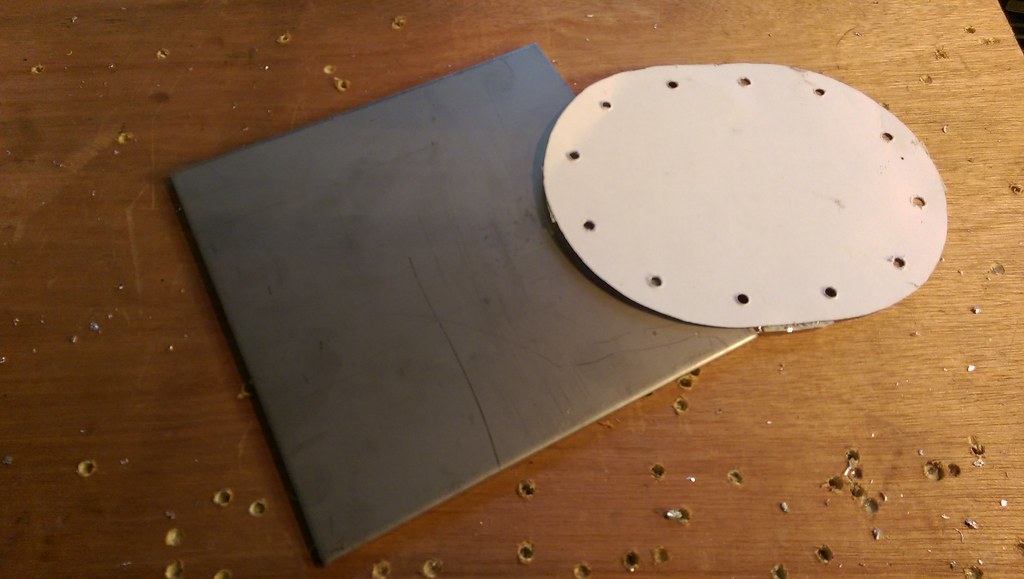

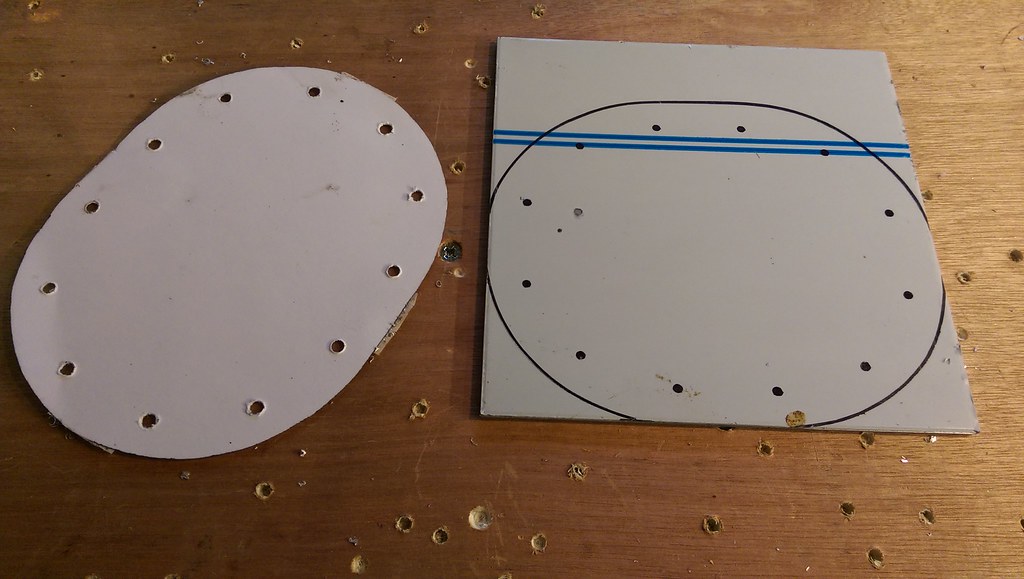

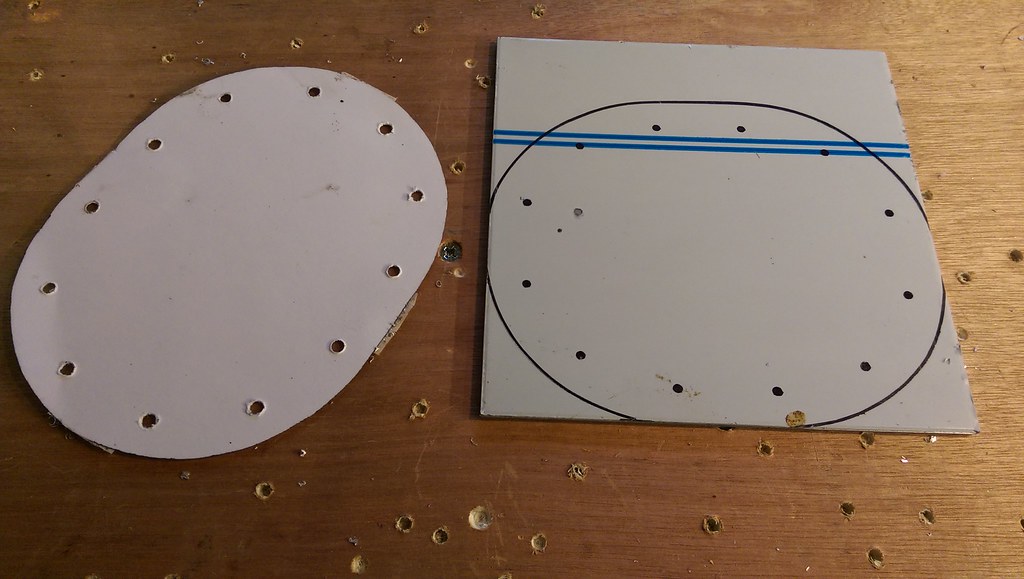

and roughed-out a lever using some photos of an original gear lever

I tried to work out an elegant way of reversing the motion at the gearbox, but eventually decided it was much easier to do it at the shifter...

The hole near the midpoint of the lever will be tied to the ally block by a clevis and rose joint, much like the Porsche 962 shifter...this should give me 1st gear left-and-forward. Not original, I know, but I'm too old to learn a new shift pattern (and remember it in the heat of the moment!).

Alongside the panelling work, I've been making some of the accessories...these are stainless steel sill covers for the tank apertures.

and roughed-out a lever using some photos of an original gear lever

I tried to work out an elegant way of reversing the motion at the gearbox, but eventually decided it was much easier to do it at the shifter...

The hole near the midpoint of the lever will be tied to the ally block by a clevis and rose joint, much like the Porsche 962 shifter...this should give me 1st gear left-and-forward. Not original, I know, but I'm too old to learn a new shift pattern (and remember it in the heat of the moment!).

Alongside the panelling work, I've been making some of the accessories...these are stainless steel sill covers for the tank apertures.

Nice work Eddy

Re hole spacing for the ali panels, I found, purely by chance, that 70mm worked pretty much all round

Re hole spacing for the ali panels, I found, purely by chance, that 70mm worked pretty much all round

Ed McClements

Supporter

Been tacking together the pedal box and mocking-up the master cylinder position and pivot bar (with Oilite phosphor-bronze bushes for the clutch & brake pedals).

Ultimately this will be adjustable for position, but for now it'll be fixed to suit the 5' 9" driver. Please excuse the state of the workbench!

Ultimately this will be adjustable for position, but for now it'll be fixed to suit the 5' 9" driver. Please excuse the state of the workbench!

Ed McClements

Supporter

Try Kenny Coleman at EDA. He builds lots of american V8s and often 302 strokers so he may have a good standard crank lying around. He built Mark's engine. He will run your engine and set up on the dyno for about £300.

Engine Data Analysis

Engine Data Analysis "Specialist Engine Building & Tuning"

Cheers

Mike

Hi Mike

I have located a good crank on standard sizes, but it's a 1995 crank which (I think) makes it a 50oz external balance rather than a 28oz which is what would have been in my 1972 302. Any issues using a later crank in an earlier block?

Eddy

Ed McClements

Supporter

Should be OK. Kenny will machine the block for the one piece crank seal when he does any other machining. He will also check the crank for any cracks and journal wear. Balance with all parts - pistons ,rods, flywheel and crank damper etc.

Cheers

Mike

Thanks Mike - I spoke to Kenny today....and my goodness he can talk! His opinion for the bottom-end was:-

- 347 stroker based on new Eagle crank (don't bother with a piddly little 302)

- Forged pistons (doesn't trust any cast piston, even hypereutectic alloy)

- Use new rods - by the time old rods have been re-worked for ARP fasteners you might as well have bought new rods

FORGED BYKB747030

MODEL 302

BORE 4.00"

STRK 3.00"

C.H 1.298"

PIN 0.927"

RINGS 1/16"-3/16"

WT 565g

CROWN F/T -4.8

C/ROD 5.40"

With a weight of 565g, they're a lot lighter than the +0.030 KB pistons (703g) and are designed for use with 5.4" rods, potentially allowing me to build a long-rod 306ci with a zero-balance factor (I haven't finished doing the maths to work out if this is possible).

I might cross-post this to the "Engines" subforum for people's views.

Cheers,

Eddy

Ed McClements

Supporter

They're Wilwoods, but very much in the style of the old Girling master cylinders. Bought here:-

http://www.rallydesign.co.uk/product_info.php?products_id=4047

http://www.rallydesign.co.uk/product_info.php?products_id=4047

Ed McClements

Supporter

He's already rebuilt my transmission - I'll have to look again at the invoice (when I'm feeling brave!) to check the details of what was done.If you are concerned about the UN-1 box look into the Chris Cole conversion to a one piece main shaft. better 1st and second gear and a limited slip.

Ed McClements

Supporter

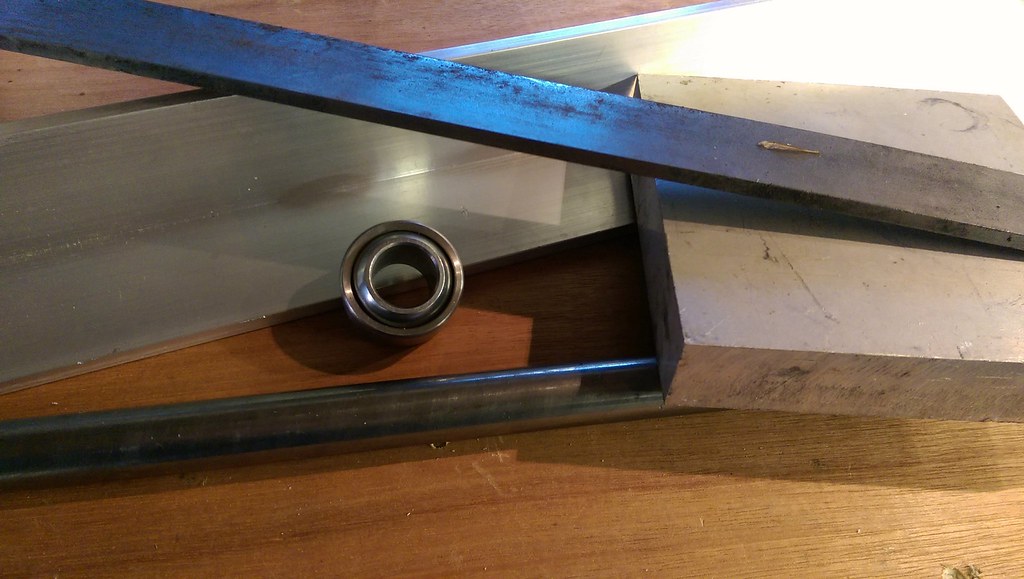

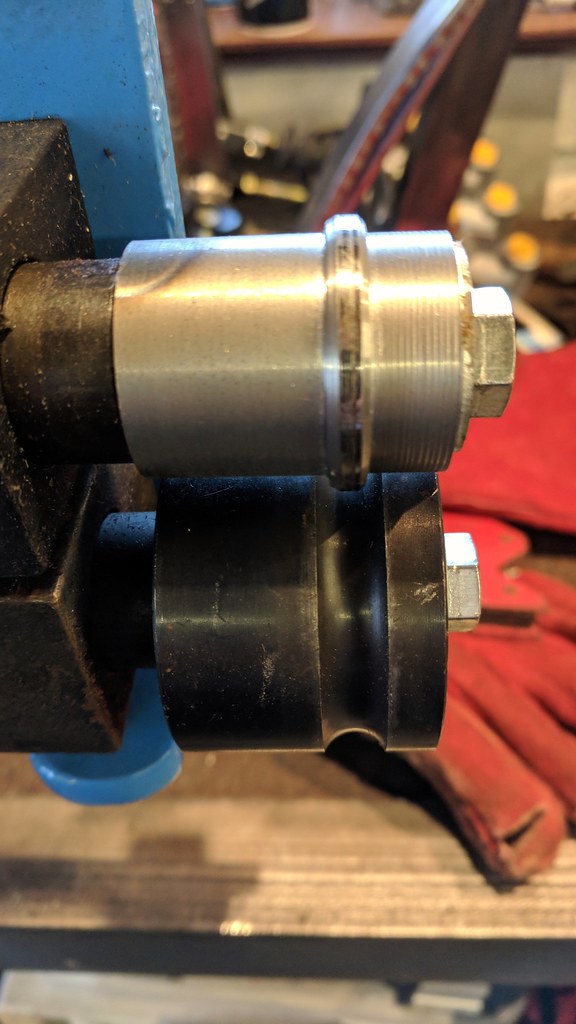

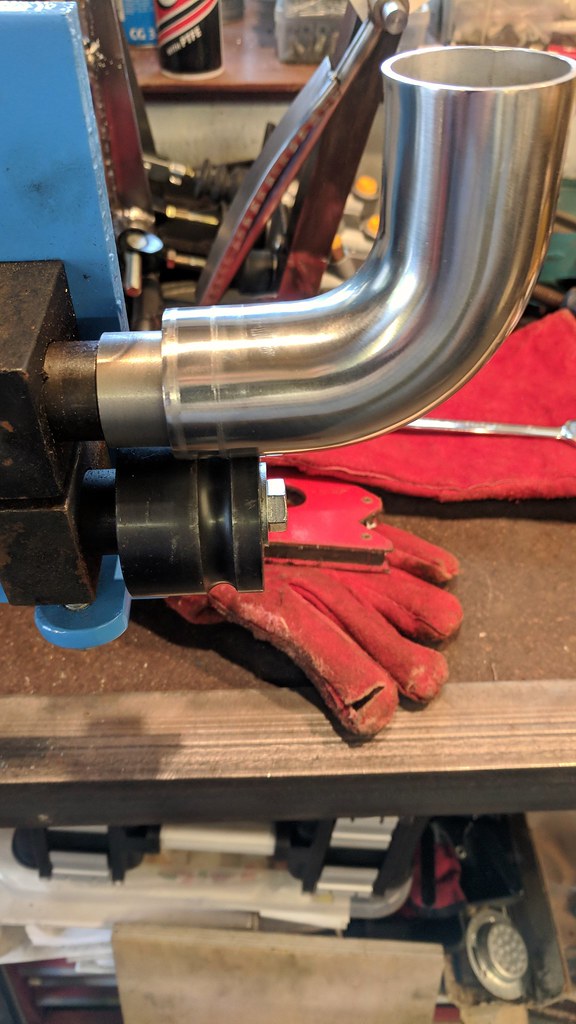

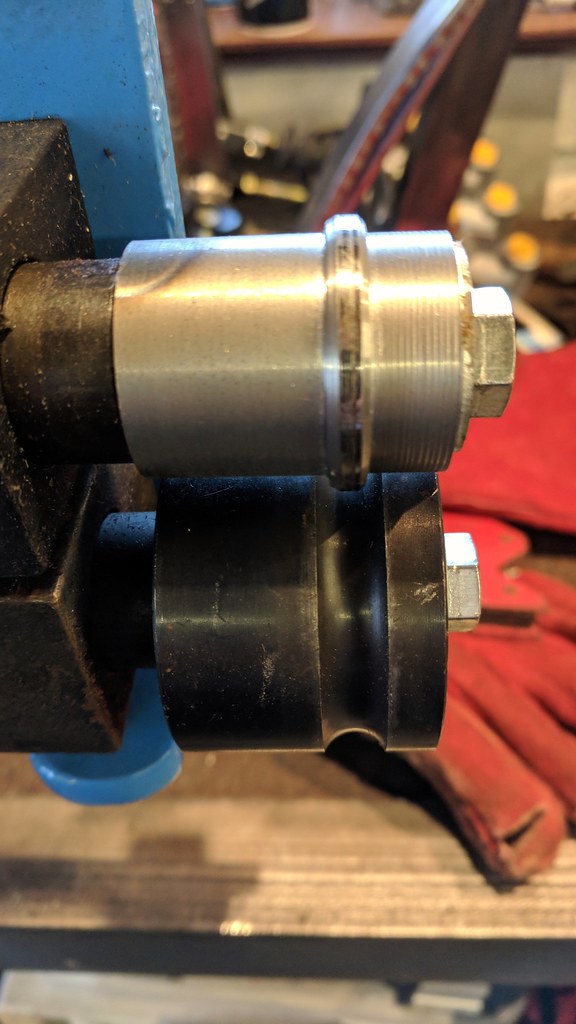

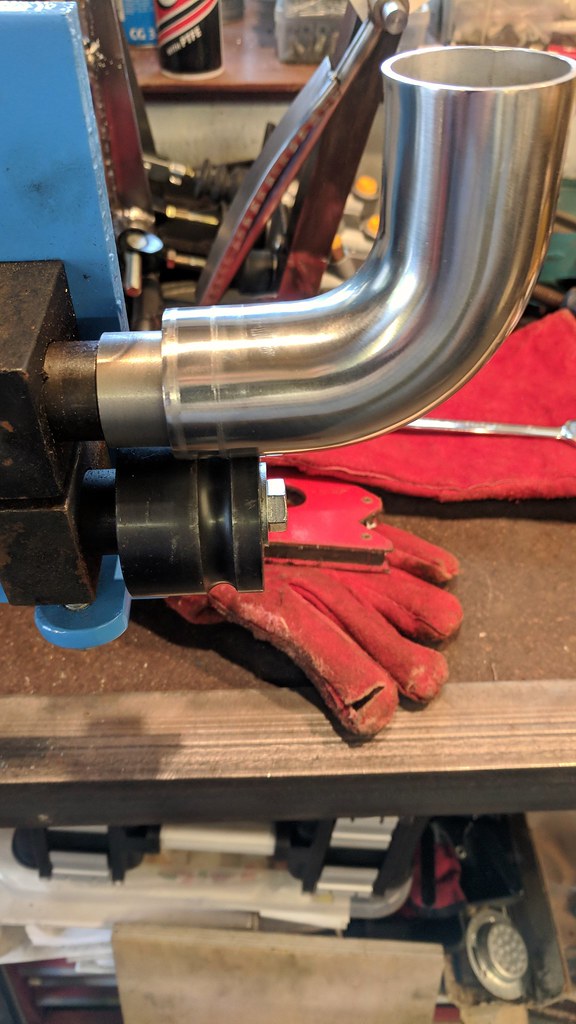

This morning, I made a new die for my bead roller - one which will fit inside the 1.5" stainless tube I'm using for coolant pipes. I wanted to roll a bead to keep the hoses from slipping off:-

I tightened-up the roller as much as it would take, but couldn't make an impression on the stainless tube - it's 1.5mm wall, and I guess the mandrel bend may have work-hardened it? Anyhow, I'll just have to think again.

I tightened-up the roller as much as it would take, but couldn't make an impression on the stainless tube - it's 1.5mm wall, and I guess the mandrel bend may have work-hardened it? Anyhow, I'll just have to think again.

Similar threads

- Replies

- 2

- Views

- 410

- Replies

- 26

- Views

- 2K