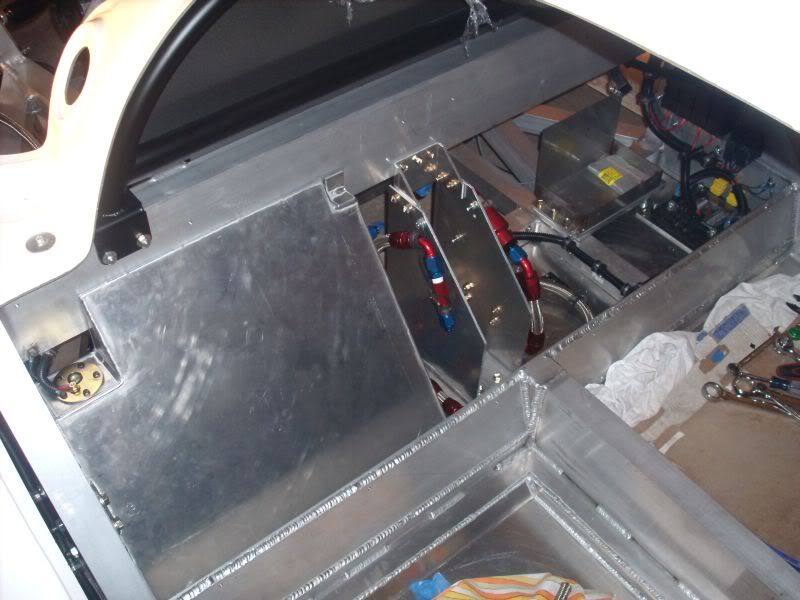

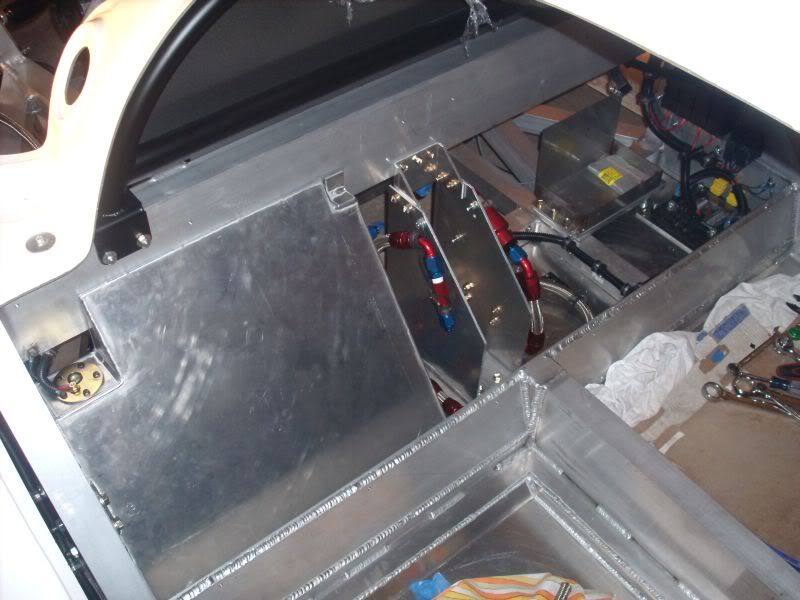

I have some of my rear electrical about 15-20'' away from my main fueling setup (aeromotive filters, holley external pump, all aeroquip braided line)

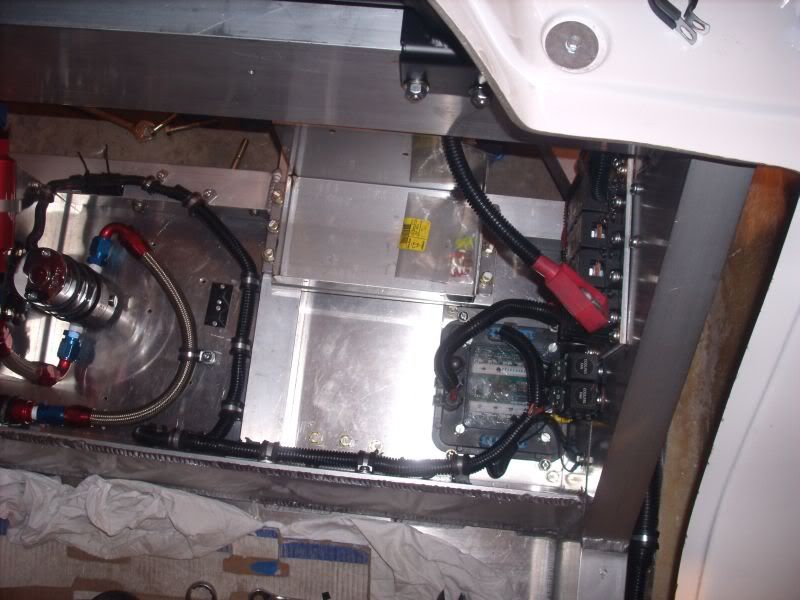

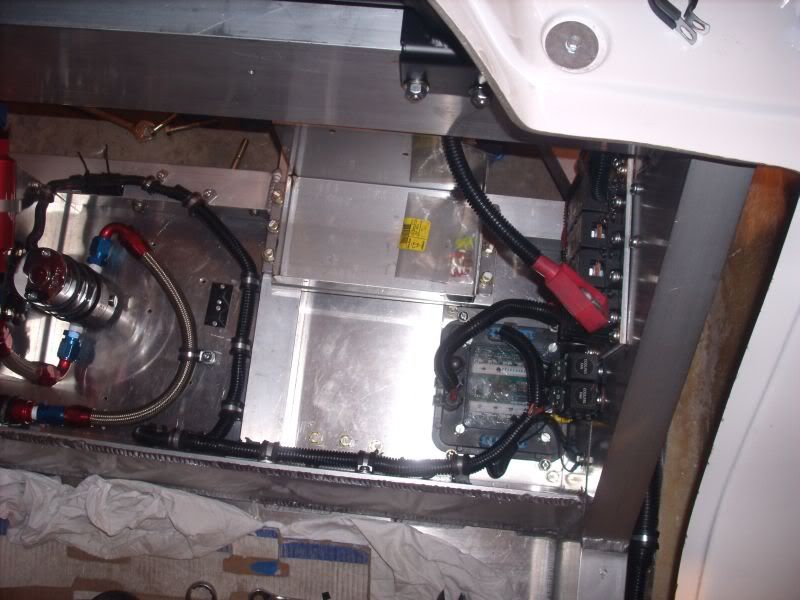

Electrical is my battery, rear ISIS unit, main fuses and a relay for my radiator fans.

I've asked half a dozen people their thoughts and nobody seems overly worried because of the amount of airflow that's available from the back. Still, I do keep wondering about it, just because I'm not 110% certain. Would you be concerned?

Electrical is my battery, rear ISIS unit, main fuses and a relay for my radiator fans.

I've asked half a dozen people their thoughts and nobody seems overly worried because of the amount of airflow that's available from the back. Still, I do keep wondering about it, just because I'm not 110% certain. Would you be concerned?