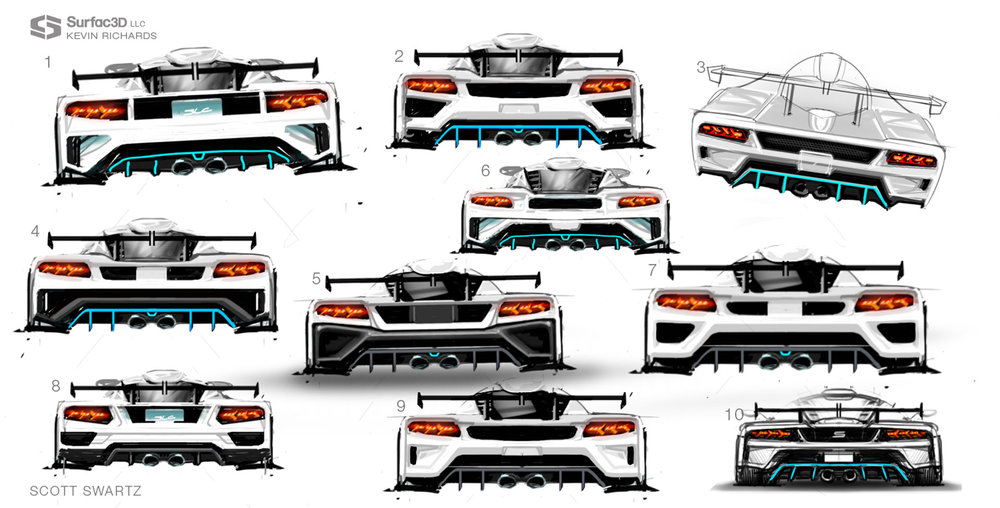

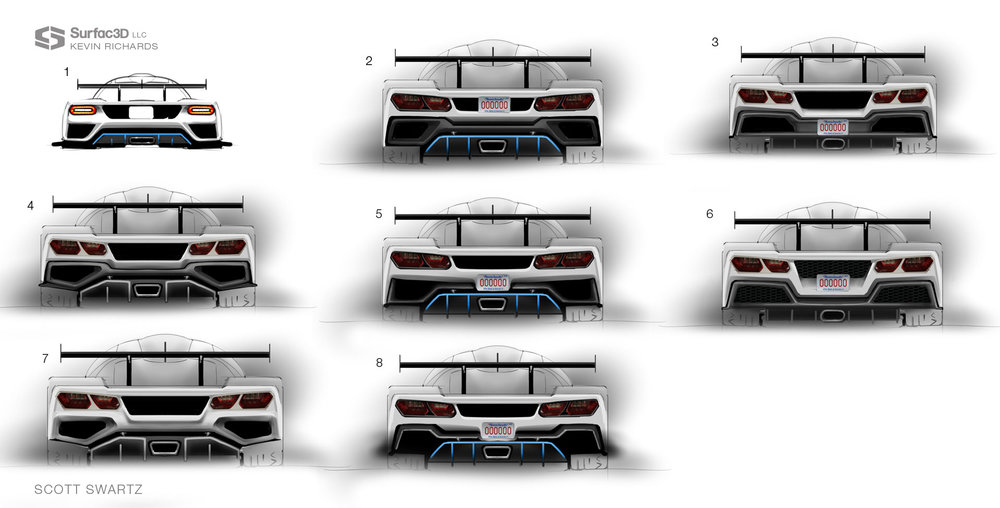

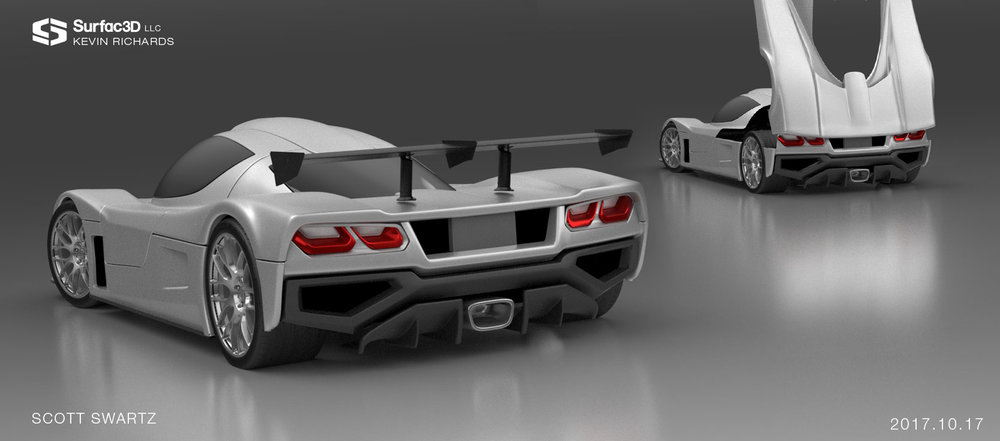

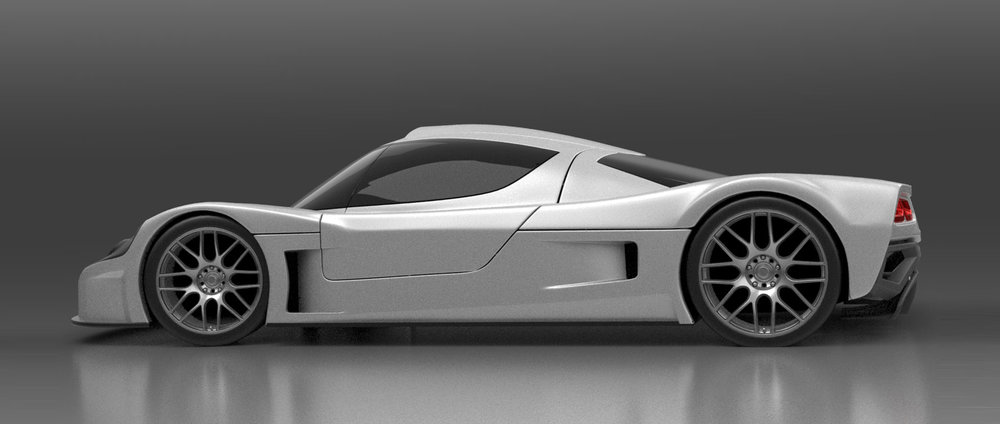

I plan on replacing the rear 12" or so of the street tail with a custom piece. I retained Kevin Richards from

Surfac3D to create the sketches and 3D models. The key design elements are:

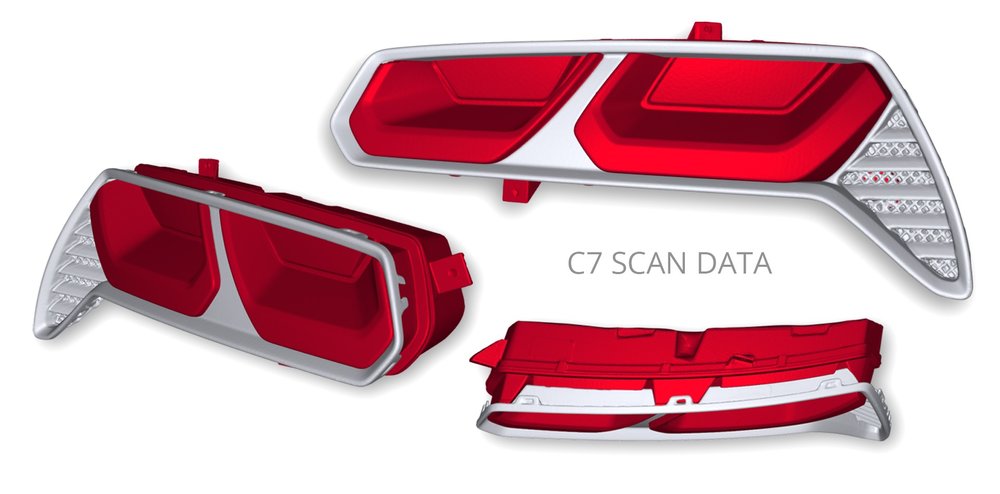

Unique taillights: While the tail lights provided in the kit are OEM, I think the car deserves something better. I don't want anything round.

More vents: The engine compartment gets hot and more vents are functional, plus they look cool.

Remove duck tail: A dynamic wing will be mounted above the tail section. The duck tail conflicts with a wing both aesthetically and functionally.

Fixed diffuser: The diffuser is molded into tail and it provides the mounting points for the hinge. This means that you need to elongate the holes for the exhaust tips to clear. While removable bezels can cover the holes, they are a pain in the ass. If the diffuser is fixed and the exhaust passes through it, there is no need for elongated exit holes or bezels. In addition, the current molded-in diffuser doesn’t appear all that functional when compared to the race tail. Lastly, the diffuser can project out the rear further which will provide more room for the exhaust (the current diffuser clears the ground by less than a quarter of an inch when the tail is in the vertical position).

Exhaust: The exhaust should exit through the diffuser, ideally with a crossover and a single Lambo-like exhaust tip. I like the external appearance and sound of Peter's exhaust, but I'm thinking of mounting the mufflers low and parallel to the ground. I have a Ricardo which is huge so I'll have to see what's possible.

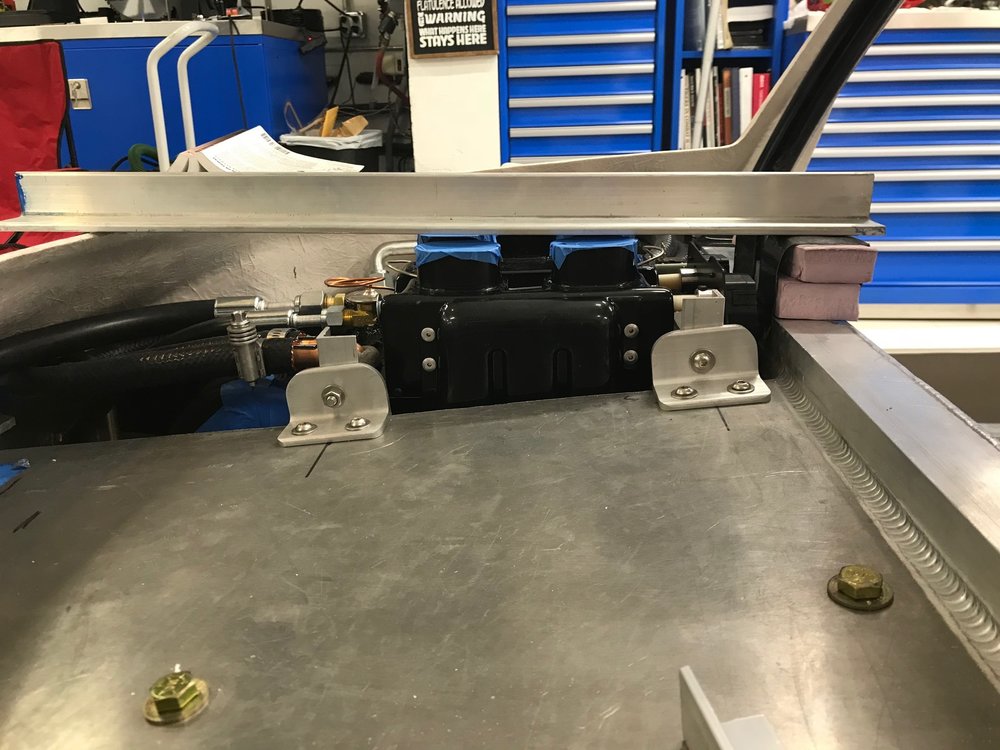

Hinging: A fixed diffuser requires a custom hinge that mounts to the top of the suspension cross brace. Given that the diffuser is fixed the pivoting piece of the tail will be much lighter.

Tire: The tires are hardly visible at all from the rear and I'd like to see a little rubber. Something midway between the street and race tails.

LAMBO LIGHTS

My first attempt was to modify some aftermarket Lambo-like sequential lights from Buddy Club as shown in

this video. I spent a bunch of time cutting them out of the huge casing, designing a 3D printed bezel and making a mold to vacuform a clear lens.

Kevin did some sketches which looked great, but when he saw the light in person he mentioned that the LEDs were pointed in a weird direction, so we powered it up and they were clearly designed to project light 20 degrees different that how they'd be mounted on the SL-C. While they'd look great, I decided that it was dangerous to have the brake lights set up sub optimally. Too bad, as they would have provided me with a completely unique look.