Running holly pumps and regulator ,all dyno on them so no problem

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ed McClements

Supporter

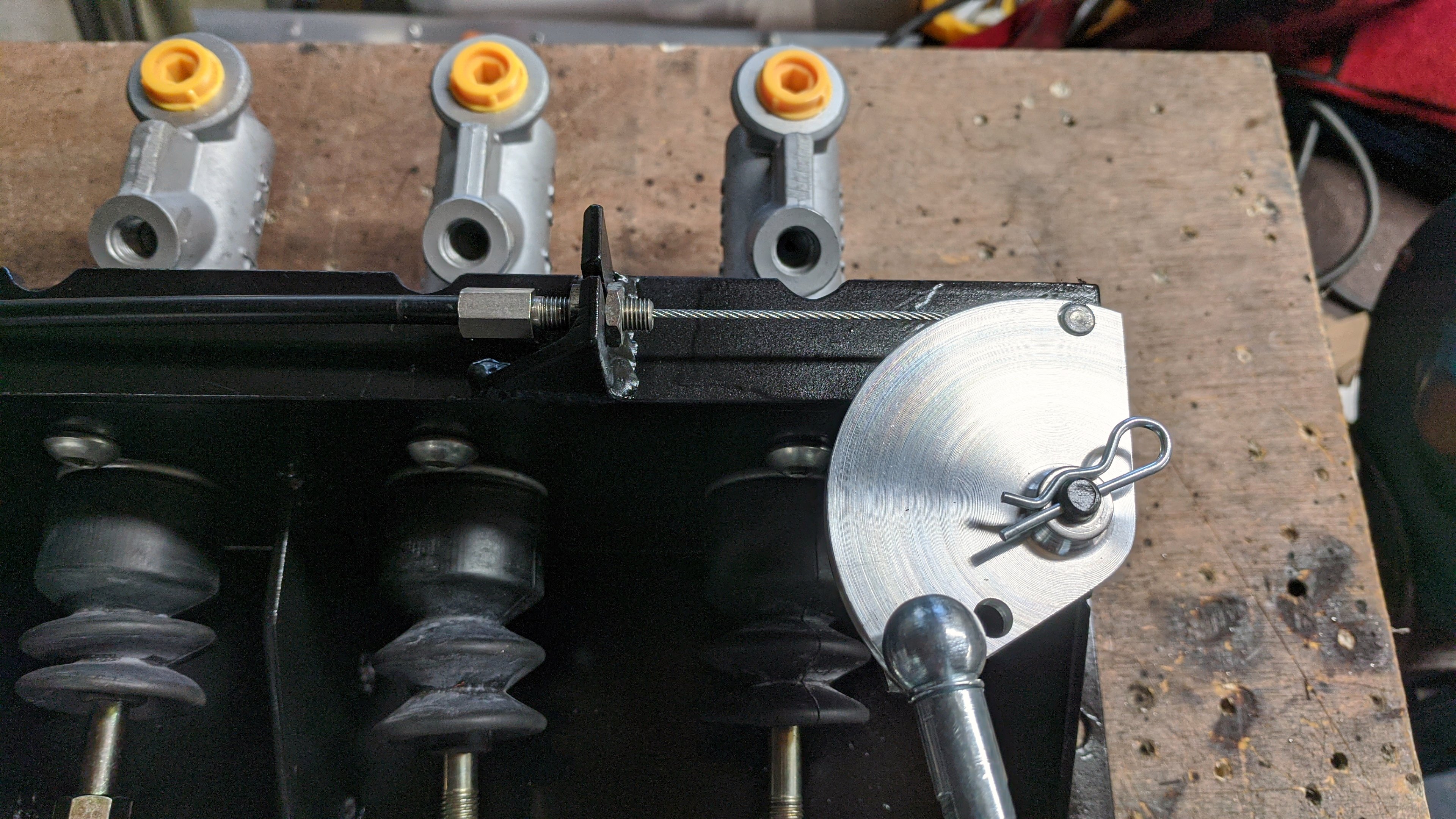

Decided that my original throttle linkage was going to stress the cable end, each time the pedal was floored...

So I cut off the pivot, and the mount for the cable and built an alternative system with a part-circle pulley which will be kinder to the cable...

There is some adjustment available to provide quicker or slower action. Question also is....how much cable pull do I need for a Holley or Edelbrock 650 CFM carb? Inch-and-a-half?

Oh, and the revised design sends the cable off towards the left hand sill, down which it will be routed to the engine bay.

So I cut off the pivot, and the mount for the cable and built an alternative system with a part-circle pulley which will be kinder to the cable...

There is some adjustment available to provide quicker or slower action. Question also is....how much cable pull do I need for a Holley or Edelbrock 650 CFM carb? Inch-and-a-half?

Oh, and the revised design sends the cable off towards the left hand sill, down which it will be routed to the engine bay.

Ed McClements

Supporter

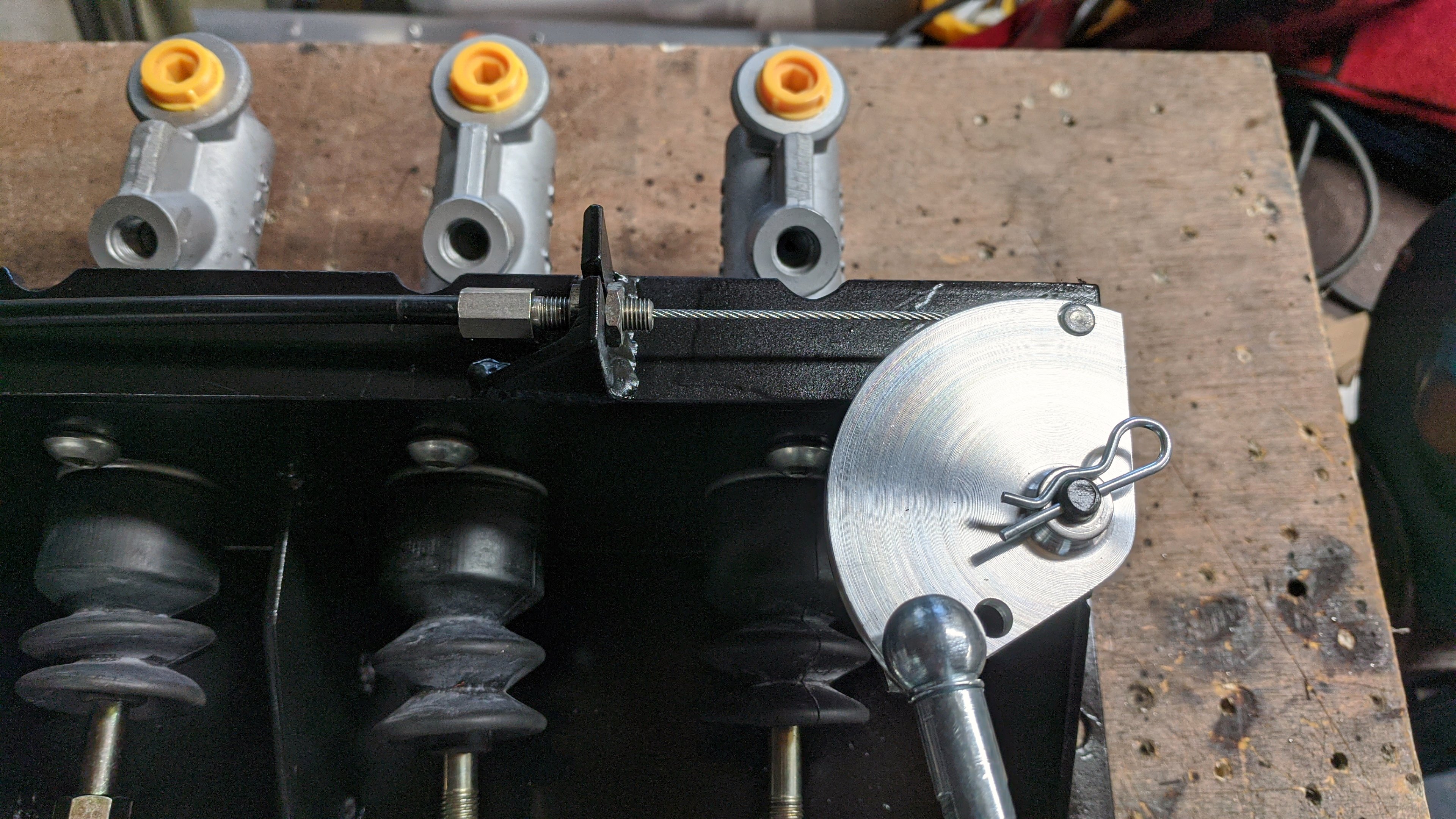

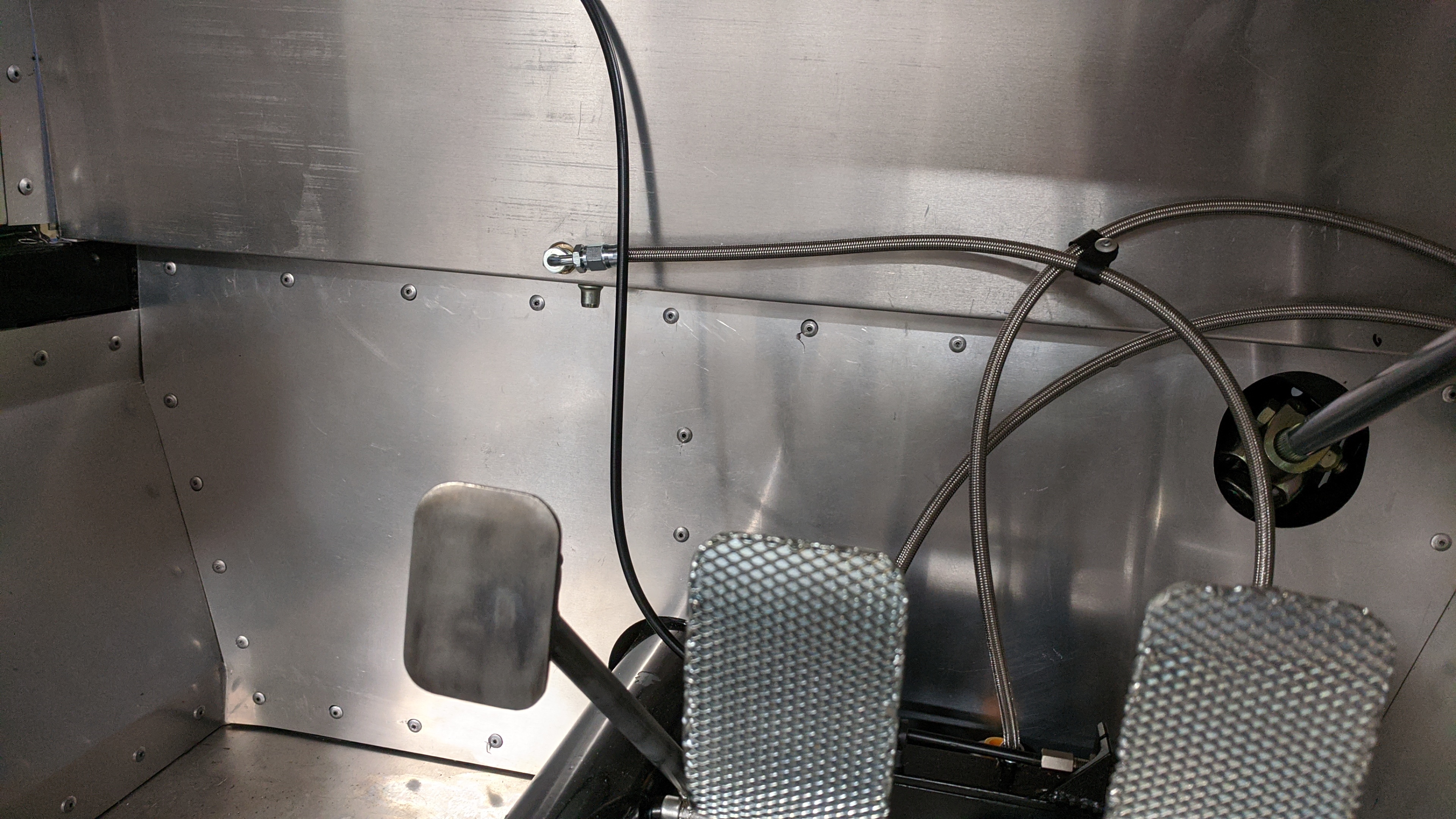

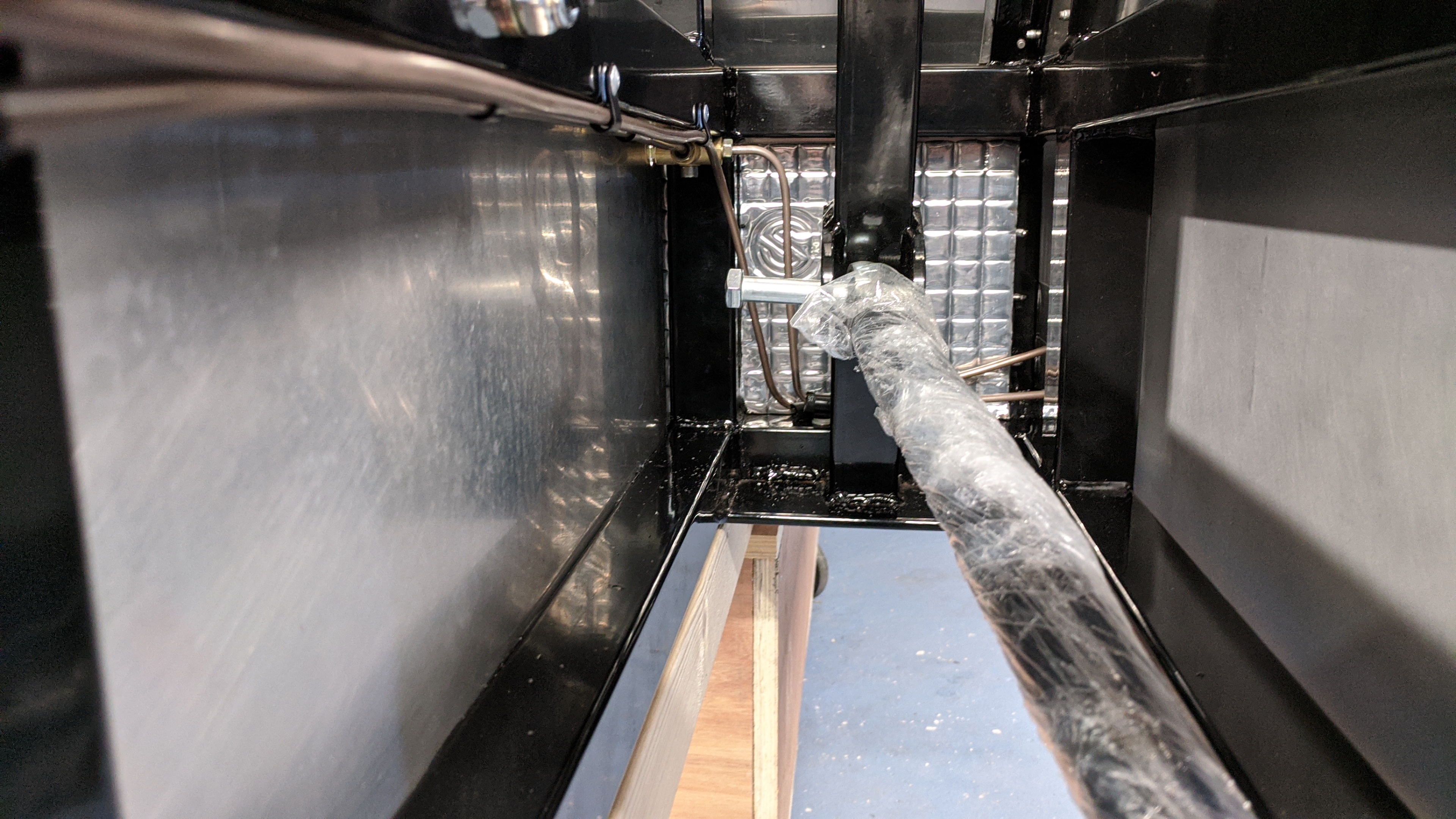

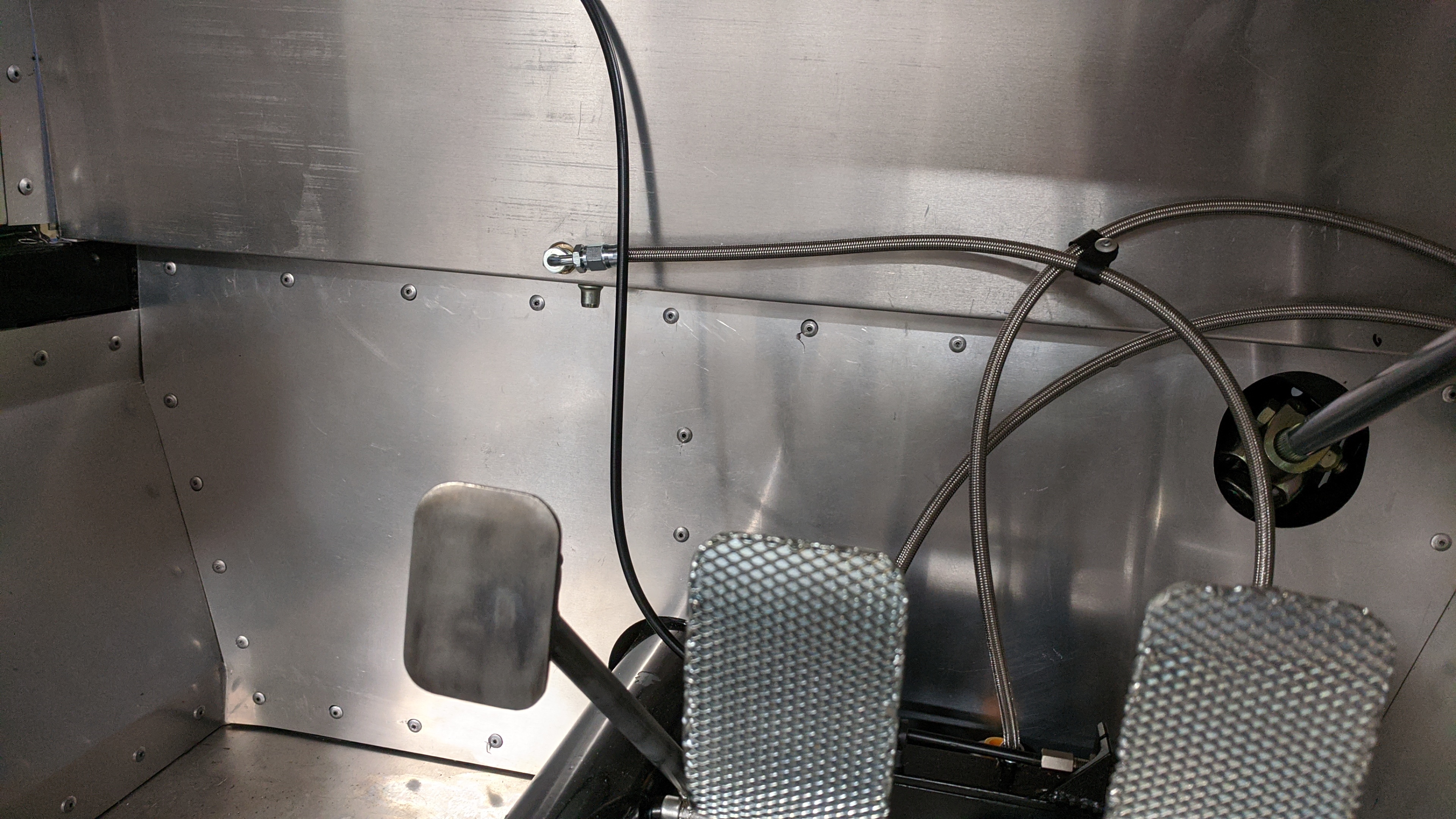

Popped the revised pedal box into place and hooked-up the plumbing...which still needs further clips, while allowing some movement fore/aft for the adjustable pedal box position.

Also been running more lines...

Front brake pipe pops through the front bulkhead...

...into a four-way tee piece which will accept the brake light switch

Also been running more lines...

Front brake pipe pops through the front bulkhead...

...into a four-way tee piece which will accept the brake light switch

Ed McClements

Supporter

One thing to check, hard to tell from photos but IVA says the max clip spacing should be 300mm, I think it looks fine but one to check maybe? Love the pedal box, really nice job

Cheers, Shaun. There are loads of clips, and I'll be adding more. Oddly, although it is oft-repeated that the IVA manual states brake clip spacing should be 300mm or less, it actually doesn't specify a minumum at all:-

It merely states "adequately clipped". However, in the General Construction section it does state 300mm for wiring:-

So you probably can't go far wrong following that. My main aim with the brake lines is to prevent then from touching the chassis, where they might vibrate and eventually wear through (eek!).

Ed McClements

Supporter

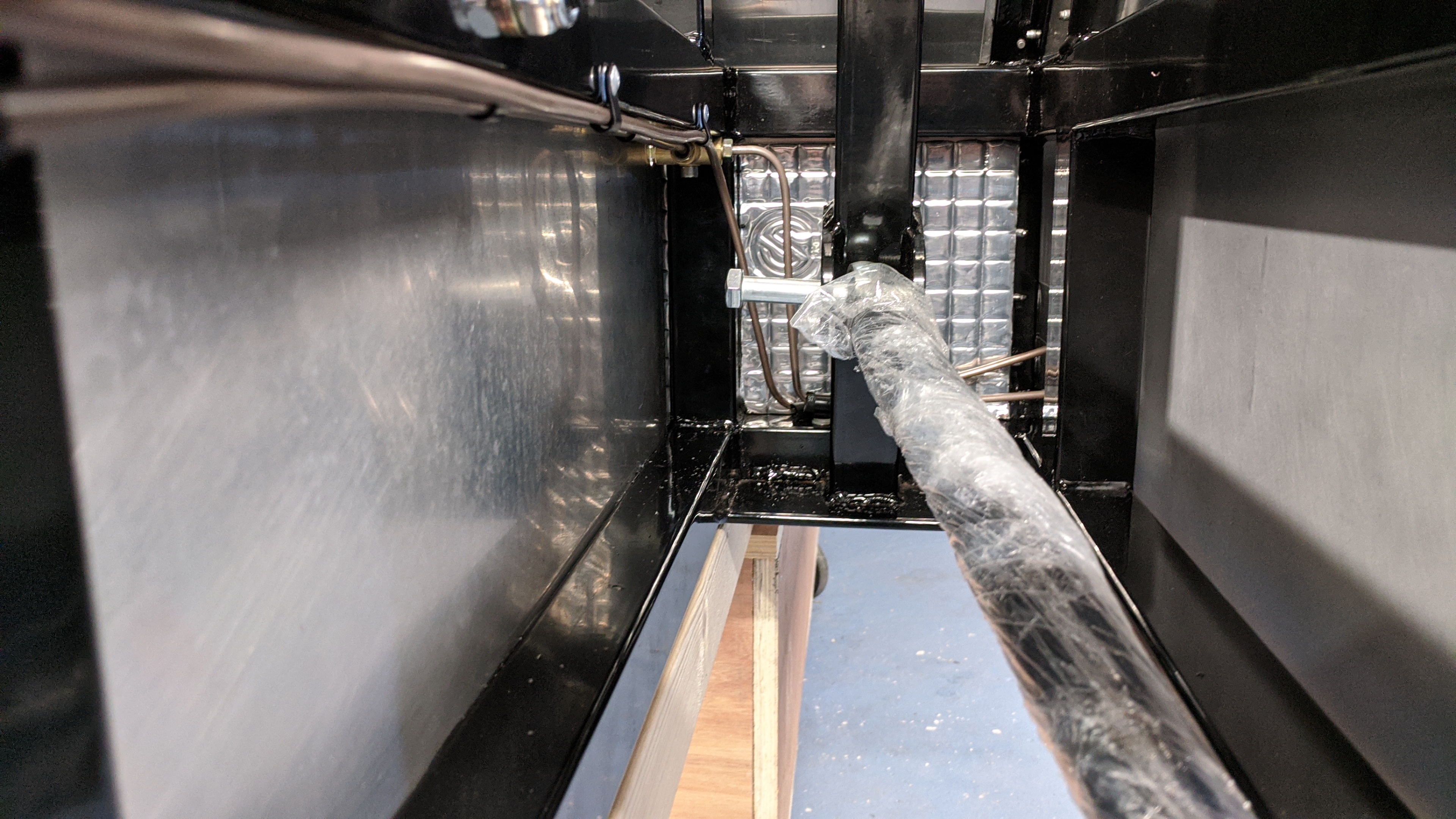

Not pictured here, but I installed a 3/8" aluminium tube down the left-hand sill with a couple of gradual bends at each end - this now contains the throttle cable, so in the event of a problem I can install a new cable without having to uninstall the fuel tank. It comes into the passenger compartment just next to the a/c hose holes at the front of the sill cover.

Shaun

Supporter

Good point Eddy as you say I think more is better to protect it form any hard surfaces, I went a little clip crazy as with rivets but they are pence so I thought best err on that side, I think it makes it look a pucker job as well which should please the tester

Got an ECU loom to fit tonight.....Gulp

Got an ECU loom to fit tonight.....Gulp

Shaun

Supporter

Going to leave mine bare, I admire those that paint them then build as they are just so easy to scratch, Mick at SGT has seen some where they are smartened up a bit with a scotch brite pad to give them a more matt look, may experiment but I am going for a bit of a stripped out look inside with bare panels as well so making my life in the build a bit easier!!

Thank youGoing to leave mine bare, I admire those that paint them then build as they are just so easy to scratch, Mick at SGT has seen some where they are smartened up a bit with a scotch brite pad to give them a more matt look, may experiment but I am going for a bit of a stripped out look inside with bare panels as well so making my life in the build a bit easier!!

Ed McClements

Supporter

Question please, do you have any plans to paint the panels if so powder coating or something different or are you leaving the aluminium bare, thank you

I think they're going to stay bare in SGT #48.

ThanksI think they're going to stay bare in SGT #48.

Ed McClements

Supporter

Calling fellow Southern GT builders...

So that I can route the clutch line and finish the gearshift linkage I needed to fit the 'box, which meant mounting the set-up block (a tatty old '72 Torino / Fairlane, I think).

Please excuse the state of the workshop!

I have Mick's engine mounts, and Chris Cole's gearbox mounts (which are way off, and will need to be returned). Even so, it's clear that the engine is slightly nose-downwards in the chassis....is this normal in SGT builds?

So that I can route the clutch line and finish the gearshift linkage I needed to fit the 'box, which meant mounting the set-up block (a tatty old '72 Torino / Fairlane, I think).

Please excuse the state of the workshop!

I have Mick's engine mounts, and Chris Cole's gearbox mounts (which are way off, and will need to be returned). Even so, it's clear that the engine is slightly nose-downwards in the chassis....is this normal in SGT builds?

Ed McClements

Supporter

This was before the new bracket was made only one fixing hole and misaligned the box, I'll take a photo later of mine now

View attachment 106055

Thanks Shaun. Currently you will see in my pic above that the transaxle is sitting on the chassis crossmember so it physically can't go any lower. The only way to get the engine level would be to have the front of the engine higher....but that's mounted on SGT mounts, which must be correct as Mick made them...?

Mike Pass

Supporter

Hi Eddy, looking good.

On my GTD as on many others with the Renault box, the engine slopes down at about 4 degrees. I have a wedge plate under the Holley carb to set it level.

Some people have used vinyl wrap on the panels. Use clear if you want the shiny aluminium look. It can be peeled off and changed if it gets tatty. You can wrap it over the rivets to keep water out.

Cheers

Mike

On my GTD as on many others with the Renault box, the engine slopes down at about 4 degrees. I have a wedge plate under the Holley carb to set it level.

Some people have used vinyl wrap on the panels. Use clear if you want the shiny aluminium look. It can be peeled off and changed if it gets tatty. You can wrap it over the rivets to keep water out.

Cheers

Mike

Mike Pass

Supporter

It might be worth mentioning that the the bolts for the Renault slave cylinder are an odd size 7mm.

I use Mick's AP clutch setup on my car. I have an adaptor plate to the Renault bell housing. After much trial and error I got to this setup. Chris Cole release bearing and upgraded carrier and sleeved down slave cylinder. I eventually settled on a 3/4" master cylinder connected by 1/4" pipe. Throw and pedal pressure acceptable. I removed the original riveted pin that holds the slave actuating rod to the clutch fork. I replaced the pin with an HT bolt and made up my own new rod of the correct length so I had a smallestl amount of backlash of a few thou. I believe Mick sells an adjustable rod for this purpose.

Cheers

Mike

I use Mick's AP clutch setup on my car. I have an adaptor plate to the Renault bell housing. After much trial and error I got to this setup. Chris Cole release bearing and upgraded carrier and sleeved down slave cylinder. I eventually settled on a 3/4" master cylinder connected by 1/4" pipe. Throw and pedal pressure acceptable. I removed the original riveted pin that holds the slave actuating rod to the clutch fork. I replaced the pin with an HT bolt and made up my own new rod of the correct length so I had a smallestl amount of backlash of a few thou. I believe Mick sells an adjustable rod for this purpose.

Cheers

Mike

Similar threads

- Replies

- 2

- Views

- 412

- Replies

- 26

- Views

- 2K