Looking good Brett, slowgress is the only way to go, gives your heed (said like your kinsmen) more subconscious processing time, will ultimately lead to a better solution. Do you have an electronic speedo? Mine is mech but I am fitting a Honeywell sensor to monitor the speed via the bolt heads on the CV adapter and have a circuit to convert the count for so I can auto adjust the assistance of the Corsa C EPAS column.

The Honeywell sensor is quite good, it has an integral magnet, so you can count notches or bolt heads. It needs a 2mm gap. The output is 0.4V so you may need a converter (to take it to 12V) for some applications.

FYI - I have developed a few microprocessor products, fog latch, push button EPAS controller,..... my latest is a speed converter for the Corsa B&C columns, allows you to convert your speed pulse count (whatever it may be) to the correct count needed by the Corsa column, so you don't have to have a switch or knob to adjust the assistance, this circuit will do it automatically.

Oh, forgot to ask, does your bracket have a notch to stop it drifting round and the sensor hitting the magnet?

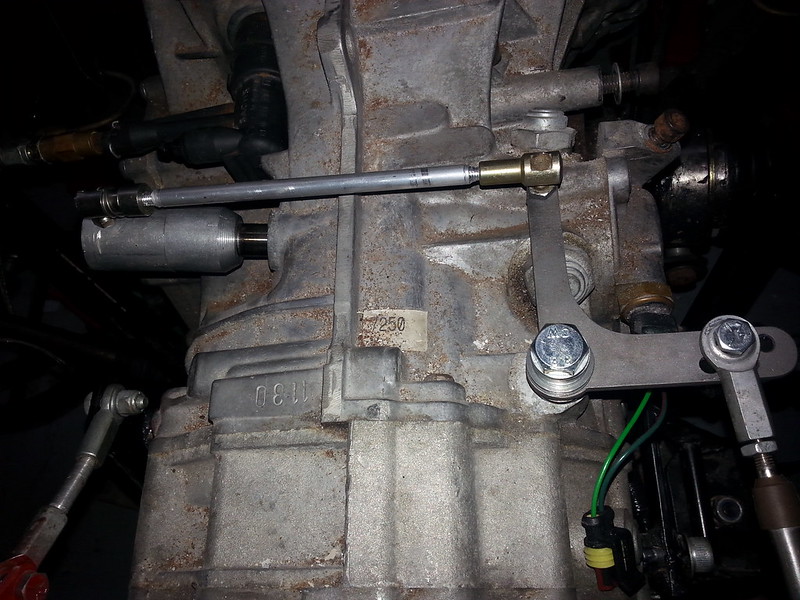

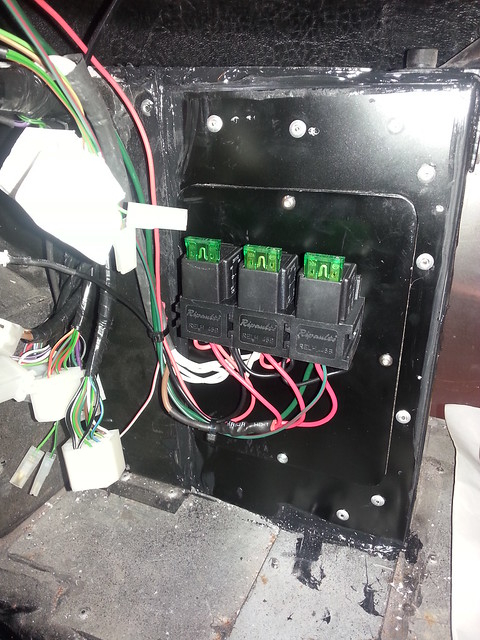

20150310_103030 by Brett-GT40, on Flickr

20150310_103030 by Brett-GT40, on Flickr