- Forums

- GT40 Replica Manufacturers' Corner

- RCR Forum - RCR40/SLC/917/Superlite Aero

- The SLC Clubhouse

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

S2's Build Thread

- Thread starter sswartz

- Start date

Joel K

Supporter

Scott, as always, great design and write up

I haven’t secured my pedals yet but have sat in the car a lot and feel this is where they will be installed.

A - Extended foot-box

B - 1.75” off the rail

C - 14.5”

My system can be moved +-2” from that position. Like you I am not confident I could nail the front to back location on the first install so the adjustable pedal gives room for error and also to accommodate others.

Lastly, you mention the height not to exceed 3/8” on the base or your design. I do notice with the RCR adjustable pedal I have it is quite tall. Keep in mind though layers of sound deadening and heat shielding will raise the floor up around the pedal base a bit. Having size 13 feet sort of overcomes the raised pedal so I think it will work for me.

Looking forward to seeing it come together.

I haven’t secured my pedals yet but have sat in the car a lot and feel this is where they will be installed.

A - Extended foot-box

B - 1.75” off the rail

C - 14.5”

My system can be moved +-2” from that position. Like you I am not confident I could nail the front to back location on the first install so the adjustable pedal gives room for error and also to accommodate others.

Lastly, you mention the height not to exceed 3/8” on the base or your design. I do notice with the RCR adjustable pedal I have it is quite tall. Keep in mind though layers of sound deadening and heat shielding will raise the floor up around the pedal base a bit. Having size 13 feet sort of overcomes the raised pedal so I think it will work for me.

Looking forward to seeing it come together.

Scott, as always, great design and write up

I haven’t secured my pedals yet but have sat in the car a lot and feel this is where they will be installed.

A - Extended foot-box

B - 1.75” off the rail

C - 14.5”

My system can be moved +-2” from that position. Like you I am not confident I could nail the front to back location on the first install so the adjustable pedal gives room for error and also to accommodate others.

Lastly, you mention the height not to exceed 3/8” on the base or your design. I do notice with the RCR adjustable pedal I have it is quite tall. Keep in mind though layers of sound deadening and heat shielding will raise the floor up around the pedal base a bit. Having size 13 feet sort of overcomes the raised pedal so I think it will work for me.

Looking forward to seeing it come together.

Joel,

Trial fitting my pedals with my size 12 shoes I find that if my foot is vertical on the brakes the tip of my shoe hits the steering column with the pedals on the floor. There is less than 1/2" clearance between my brake pedal pad and the steering column. I have the stock steering column and you have gone a different route so yours may be different but I 100% agree with Scott, you do not want to raise the pedals much at all if possible. I would also suggest not having any sound deadener, heat sheilding, or any other item between your pedal assembly and the floor. You want this mounting to be as rigid as possible.

There is a guy named Mike Patey on youtube that does amazing fabrication of aircraft components using solid works. Check him out on You Tube. He doesn't disappoint. BTW- he is a master at carbon fiber fabrication too.Abe welded the coolant expansion tank. This was the first time that I had used SOLIDWORKS’ sheet metal features. Spending the time to ensure a 50% overlap for all edges resulted in perfect fitment with optimal corner weld joints.

View attachment 107565

View attachment 107566

View attachment 107567

Scott

Lifetime Supporter

Neil, I was originally planning on using 4130. However, when I uploaded the design to 3DHubs to get a CNC quote, the only options for alloy steel were 4140, 4340 and 1215.4130 may be easier to find and will be sufficiently strong.

Joel, at this point, I'm not planning on putting any sound deadening on the floor around the pedals... but time will tell;-)

Michael, that guy has some mad skills!

The coolant expansion tank is almost finished. Four aluminum spacers were welded to the side of tank to mount it to the fire wall. They provide a 1/4” gap between the firewall and the tank. Like everything else in the car, it’s a tight fit.

There are no mounting spacers on the bottom of the tank because the rear hoop has a cross tube in that location.

The connectors for the coolant level gauge have been added, but the company that I ordered the sight tube from is closed due to Covid. The large -10 fitting on the bottom connects to the electric water pump's inlet. The smaller -4 fitting connects to the top of the coolant swirl pot.

The two -4 connectors on the top right are for radiator bleed and the other for the engine steam.

Last edited:

Scott

Lifetime Supporter

I was away from the car for a month so I had spent a lot of time designing the adjustable pedal box in CAD. I got to spend some time with the car this past week and the CAD fantasy didn’t fit reality. Specifically, the Front Suspension Race Cage wasn’t were it was supposed to be. I’m sure my initial measurements were correct so the high humidity must have warped the monocoque and cage - LOL.

After an appropriate amount of profanity, I realized that the structure was significantly overbuilt for my needs and that it could be easily modified. However, to do that I needed to remove the interior tub which meant that the body, six-point roll cage and dashboard needed to be removed… and then I realized that the steering column also needed to be removed. So I went from something that looked like a car to the following.

The Front Suspension Race Cage adds a lot of structure. The left and right sides are symmetrical and each has the following connections:

The horizontal tube in the lower right corner captures the 5/8” screw that mounts the lower control arm in the billet bracket. Note that the standard removable side impact bar option would reduce this piece to just the vertical tube, top/bottom plates and interlocking tube connectors on the left.

The bottom 1-1/2” of the tube and plate were cut in half to provide clearance for the sliding pedal box assembly.

A 1/8” gusset and end cap were welded to the notched section.

While this change reduces the strength of the tube I’m not concerned because the monocoque is already stiff and very few cars have this structure at all. The next step is to mock the sliding pedal box.

After an appropriate amount of profanity, I realized that the structure was significantly overbuilt for my needs and that it could be easily modified. However, to do that I needed to remove the interior tub which meant that the body, six-point roll cage and dashboard needed to be removed… and then I realized that the steering column also needed to be removed. So I went from something that looked like a car to the following.

The Front Suspension Race Cage adds a lot of structure. The left and right sides are symmetrical and each has the following connections:

- Eight 3/8” screws through the floor.

- Four 3/8” screws through the transverse beam in the top of the monocoque and into the front hoop’s mounting plates.

- Six 3/8” screws through the monocoque and into the upper control arm and shock absorber brackets. Hex nuts are welded to the plate which means that you don’t need a second person to keep the nut from spinning when removing or installing the brackets.

- One 5/8” screw through the billet lower control arm bracket.

- Two screws through the interlocking tube couplers that affix the removable side impact bars.

The horizontal tube in the lower right corner captures the 5/8” screw that mounts the lower control arm in the billet bracket. Note that the standard removable side impact bar option would reduce this piece to just the vertical tube, top/bottom plates and interlocking tube connectors on the left.

The bottom 1-1/2” of the tube and plate were cut in half to provide clearance for the sliding pedal box assembly.

A 1/8” gusset and end cap were welded to the notched section.

While this change reduces the strength of the tube I’m not concerned because the monocoque is already stiff and very few cars have this structure at all. The next step is to mock the sliding pedal box.

Scott

Lifetime Supporter

Back to working on the adjustable pedal box. I purchased a compact ACME nut from McMaster, but I realized that there was no pressure rating for it on their website so I sent them an email inquiry. Here’s their response…

Fortunately, McMaster offers a precision ACME nut with a 1,200 pound dynamic and a 4,000 pound static rating. Given that braking is a static activity insofar as the ACME nut is concerned, that’s an ~8x safety factor. The extra weight, size and cost are worth it.

The lead screw bracket was made from 1/4” right angle and welded 1/8” gussets. The flanged ACME nut (bronze) is mounted so that the flange is in compression when braking. In other words, the screws in the flange only come into play when the pedals are being adjusted towards the driver. Even if they fell out, both braking and forward adjustment would continue to work

Completed bracket. A hex nut was welded to the screw to allow manual adjustment (both are 18-1 stainless steel).

I mocked the adjustable pedal box with laser-cut plywood and 3D-printed gibs. Note the bracket and ACME screw in the upper right of the pedal plate.

I discovered that my pedal plate wasn’t wide enough to allow the right gib to clear the throttle pedal. This was the third or fourth time that I’ve tweaked the width of the plate. This is easy to do, but I also need to remember to change the dimensions of the bottom plate. As a software guy, hard coding interdependent values in multiple files just feels wrong. I was also getting tired of doing the math on the gib/plate tolerances every time I made a change. Fortunately, SOLIDWORKS provides an easy way to provide global dimensions, variables and equations that can be used across mulitple parts and assemblies. If I change one of the variables everything is automatically updated. This also makes it easy for someone looking at the design to understand the clearance between the gibs and the plates without needing to open up multiple files and do the math.

I’m still trying to figure out the best place to locate the gibs and the hole in the floor. I complied the list of responses which is shown below. Even for drivers of the same height there will be variances due to differences in inseam, seat recline, seat padding, etc. The 5’-11” driver with the 12” position seems to be an outlier. If anyone else sends me measurements, I’ll compile them.

Let me think about that failure mode… If the nut doesn’t hold up to the braking pressure the brake pedal will slide forward and since I’m strapped into a six-point harness I won’t be able to slide forward to even reach the pedal. This would likely be discovered during a panic stop so I might not be around to return it for credit. Yeah, let’s not try that. Nothing against McMaster, the tech person had no idea of my intended application.I spoke with our manufacturer and they do not have a static rating for the 12"-10 bronze Acme nut (95120A111). If you purchase the item and it doesn't work for your application, you can always return it for full credit.

Fortunately, McMaster offers a precision ACME nut with a 1,200 pound dynamic and a 4,000 pound static rating. Given that braking is a static activity insofar as the ACME nut is concerned, that’s an ~8x safety factor. The extra weight, size and cost are worth it.

The lead screw bracket was made from 1/4” right angle and welded 1/8” gussets. The flanged ACME nut (bronze) is mounted so that the flange is in compression when braking. In other words, the screws in the flange only come into play when the pedals are being adjusted towards the driver. Even if they fell out, both braking and forward adjustment would continue to work

Completed bracket. A hex nut was welded to the screw to allow manual adjustment (both are 18-1 stainless steel).

I mocked the adjustable pedal box with laser-cut plywood and 3D-printed gibs. Note the bracket and ACME screw in the upper right of the pedal plate.

I discovered that my pedal plate wasn’t wide enough to allow the right gib to clear the throttle pedal. This was the third or fourth time that I’ve tweaked the width of the plate. This is easy to do, but I also need to remember to change the dimensions of the bottom plate. As a software guy, hard coding interdependent values in multiple files just feels wrong. I was also getting tired of doing the math on the gib/plate tolerances every time I made a change. Fortunately, SOLIDWORKS provides an easy way to provide global dimensions, variables and equations that can be used across mulitple parts and assemblies. If I change one of the variables everything is automatically updated. This also makes it easy for someone looking at the design to understand the clearance between the gibs and the plates without needing to open up multiple files and do the math.

I’m still trying to figure out the best place to locate the gibs and the hole in the floor. I complied the list of responses which is shown below. Even for drivers of the same height there will be variances due to differences in inseam, seat recline, seat padding, etc. The 5’-11” driver with the 12” position seems to be an outlier. If anyone else sends me measurements, I’ll compile them.

I really like these Lamborghini style taillights. I am thinking of doing the same. I am not a fan of the simple round lights either. In fact, I love just about everything about Ferraris....except the taillights. Believe it or not this was one of the reasons, why I am going the SLC route versus buying a used 458/488. Really don't like the taillights of the Ferrari.View attachment 102928

Morimoto has released Aventador-inspired tail lights for the 2014-2019 C7 Corvette. They’re DOT-compliant and feature optional sequential turn signals. I’m not sure why they’re not listed on their website, but I purchased a set from Vette Lights.

In the image above, the right tail light is a 3D scan of the stock C7 tail light and bezel with the “fang” removed. The tail light on the left is cut from a photo I took of the Morimoto light. While my graphics hack job is pretty bad, I think I like the Aventador style a lot more. I asked my daughter which she preferred and she responded “the one on the left because it looks meaner” — that’s my girl

The one wrinkle is that they placed the backup light in the “fang” which I plan to cut off. I have two options:

Thanks to some help from Ken regarding the connector pin mappings, I was able to get them wired up on the bench. I’m sure there’s a way keep the lights from blurring the video, but it escapes me.

- Put the backup lights somewhere else.

- Modify the fang so that it’s flush with the bottom of the tail light. That might provide enough space to retrofit some backup LEDs into the lower outer corner. Filling in that corner may also make the lights appear more fit for purpose.

Regarding the backup lights, do you think it is possible to put the strip of high intensity white LED lights on the top or the bottom of the Lambo tail light as an upper or lower edge?

Would love to see them when you are done.

Scott

Lifetime Supporter

Brian, those tail lights won't be easy to blend because the back of the SL-C is flat whereas the C7 is curved. I'm completely reworking the back section of the tail to fit the curvature of the lights. If I recall correctly, the arc extends the tail about 3" in the middle. The picture below shows the bow (it's an old rendering so it's missing the side scoops, etc.) This works for me because I need a little more room for the transaxle, exhaust and diffuser plus, IMO, the car is a little too flat in the back. I considered rotating the tail lights a bit to split the difference on the curve, but that aims the LEDs in a sub optimal direction and I want someone following me to see the lights they way that they were designed.Regarding the backup lights, do you think it is possible to put the strip of high intensity white LED lights on the top or the bottom of the Lambo tail light as an upper or lower edge?

With respect to your question regarding the back up lights. If a LED strip were to be added immediately above or below the tail light it would need to be curved and that would be hard to make look right. I'm finishing up the molds for the brake ducts and finalizing he design on radiator outlet. Once I get those smaller body mods sorted out, I'll move back to the tail.

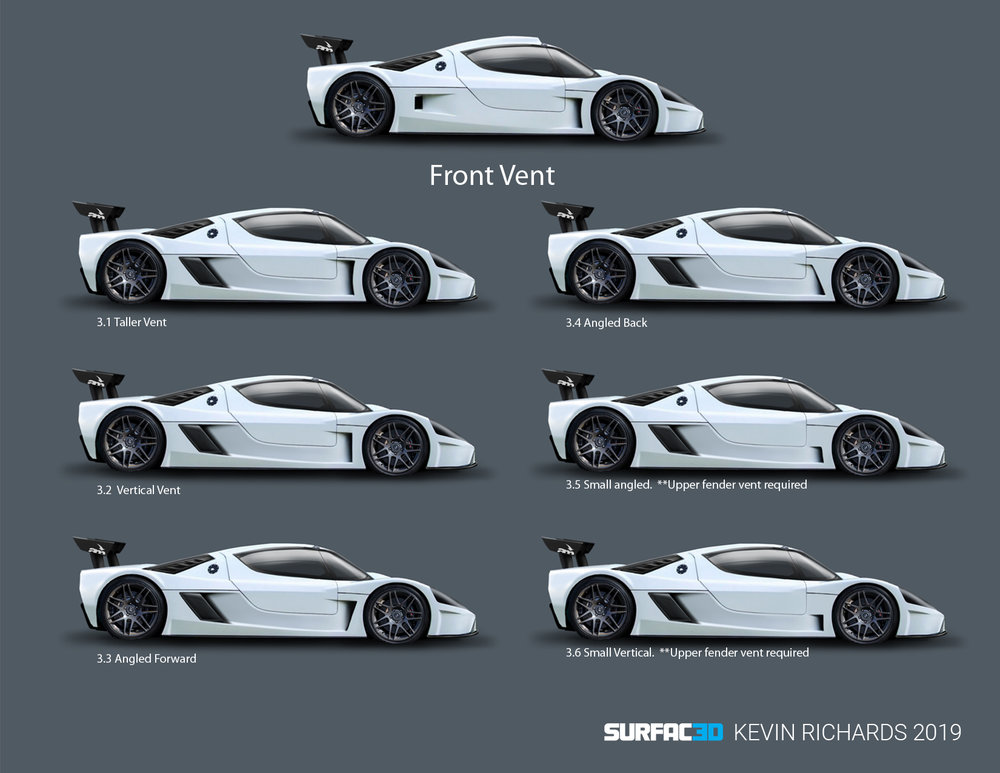

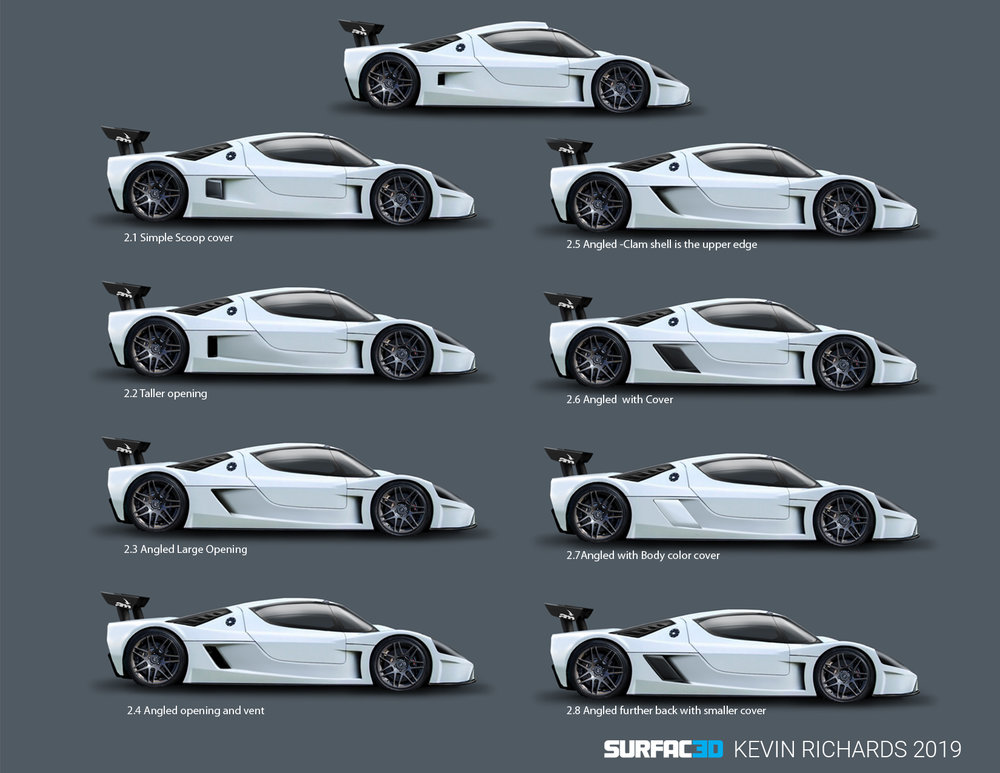

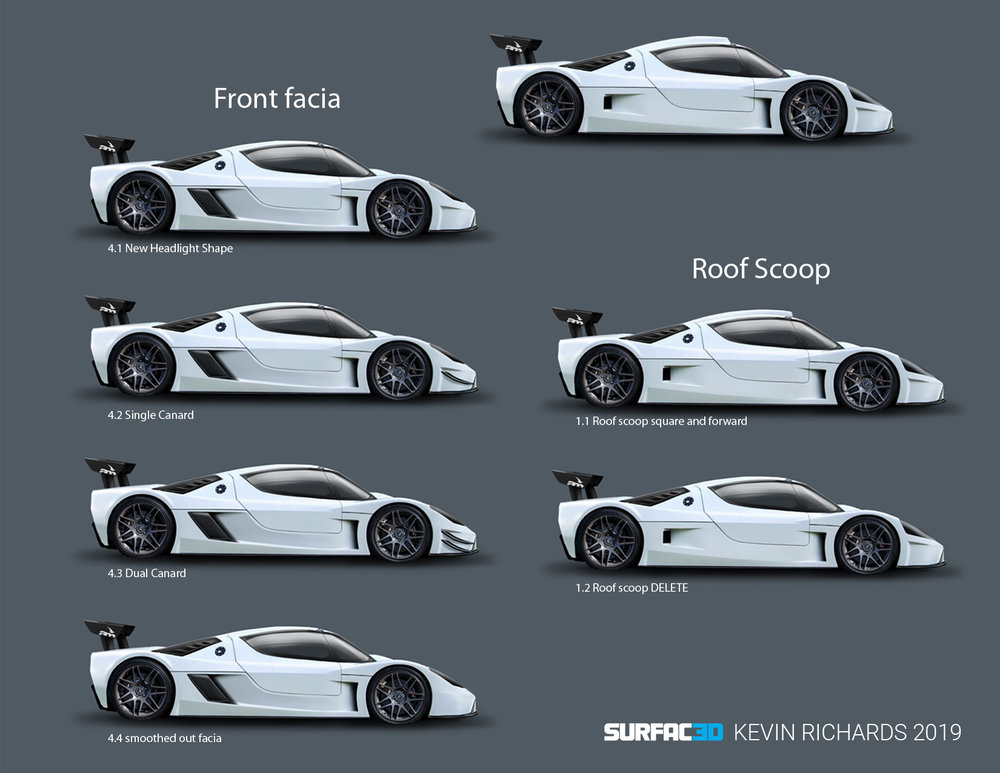

Scott et'alThe SL-C has been around a while and still looks great, but I’d like to modernize it a bit. Before I embark on changing the tail as discussed in a previous post, I’d like to go through the design, CNC cut male buck, fine tune buck, make female mold, make part, blend part into body process a couple of times on simpler parts. Specifically, the rear side scoop and roof scoop.

IMO the rear side scoop is a little small and likely doesn’t capture a ton of air — that said, I’m primarily focused on aesthetics. So I want a larger vent and to dish the side of the car like many modern cars. While dishing the doors would look great, that’s a lot more work than I want to even consider.

I’m also thinking about changing the roof scoop. I’ve always had mixed thoughts about it ranging from it’s cool to it’s a bit of a bubble sitting on top of a bubble. I’m thinking about shaving it off or making it more aggressive (i.e., rectangular). I was leaning towards shaving it because it’s cleaner and I didn’t think it was very functional… that discussion led to pnut’s recent post which indicates that at road speeds it appears to work pretty well.

Kevin did such a great job on the tail that I had him do a bunch of 2-D renderings. Here’s a bunch of variants.

Currently leaning towards this one..

How far on the bottom side can we extend the "side vent". I am very interested in doing something on the rear side vent. IMHO - I think the rear side vent is too small and too angular. The car has great curves but that vent looks too square to my eye. I don't have the luxury of having a car here (Fran is doing my turnkey build) so I don't know how much space is required by the piping etc...

I would like to do something more curved like Koenigsegg or McClaren. I Obvisously wouldn't go as deep on the vent to affect the door. Probably keep it just below the door and not as deep but something like that. Do you think that is possible?

Attachments

Mason - that is really helpful. Could you share your model files. My 17 y/o son is a budding engineer and would love to play with options and has two cad options. He already downloaded the other version from here on the blog but the but the door doesn't appear correctly (it looks rounded).Hey Brian,

See below for a cut away of the rear vent area. The green block by the door is 7" thick. The block by the wheel is 16.5" thick.

You could go fairly deep on the body cut out but would need 2" thick channel near the bottom for coolant pipes.

View attachment 108761

Question - What is the Green box under the door and is there any room between the body panel and the green box? I would like to have my indent vent reuse the lines of the side window and be a little longer and wider than the current side vent

Thanks

Scott

Lifetime Supporter

Brian, I assume you're asking about the green box immediately behind the door. If so, that illustrates the available space between the monocoque and the body. Below that green box is where the cooling, heating and A/C lines go. How much actual space you have depends on where those lines are located.

Below is the current design. I thought about scalloping the doors, but that's too much work. I could easily make the indent deeper starting at the aforementioned green box, but I only have an oil cooler on the left side an cold air box on the right so there is no need and I don't think that it improves the aesthetics. I could easily make the carbon fiber scoop protrude more, but I don't like that look and I don't need that much air.

Below is the current design. I thought about scalloping the doors, but that's too much work. I could easily make the indent deeper starting at the aforementioned green box, but I only have an oil cooler on the left side an cold air box on the right so there is no need and I don't think that it improves the aesthetics. I could easily make the carbon fiber scoop protrude more, but I don't like that look and I don't need that much air.

Last edited:

OH - So the GREEN box is illustrating the "Available Space" that we could use for the vents as long as we allow for hoses.Brian, I assume you're asking about the green box immediately behind the door. If so, that illustrates the available space between the monocoque and the body. Below that green box is where the cooling, heating and A/C lines go. How much actual space you have depends on where those lines are located.

Below is the current design. I thought about scalloping the doors, but that's too much work. I could easily make the indent deeper starting at the aforementioned green box, but I only have an oil cooler on the left side an cold air box on the right so there is no need and I don't think that it improves the aesthetics. I could easily make the carbon fiber scoop protrude more, but I don't like that look and I don't need that much air.

View attachment 108777

Here is a mockup of what my 17 y/o son is doing for me. Took him 2 hours to do using the scanned models. We are using the same exact lines and shape as the side window for the side vent. I just wish the scanned version was of a completed car because you can see prevalent gaps in many areas around the doors and where the body fit together. NOTE - If anyone has better models that are already cleaned up to remove these gaps I would greatly appreciate them.

I am also going to be adding these carbon fiber side skirts that I sourced this week. I think they add a modern yet sexy dimension to the car. We are going to continuing editing to so that the gold pinstripes will be on the leading edges.

Last edited:

I love the renderings, wish I could 5% of that.

Brian, I had a 3D model I paid for (can't recall website). I'd be glad to share it with you or anyone here, send me a PM with email and I'll get it to you.

Scott, those carbon headlight buckets looks great. Something I always wondered how it'd look and dig it.

Brian, I had a 3D model I paid for (can't recall website). I'd be glad to share it with you or anyone here, send me a PM with email and I'll get it to you.

Scott, those carbon headlight buckets looks great. Something I always wondered how it'd look and dig it.

Scott

Lifetime Supporter

Mason, the radiator outlet will be made out fiberglass and it will be bonded to the nose. It will be fed via a fixed duct, made from aluminum or fiberglass, that's sealed to the shroud. I'm currently working on the outlet size to create a diverging-converging duct to maximize mass airflow. There will also be a La-Ferrari-Style vane to reduce drag. The airfoil will be 3D printed and covered in carbon fiber. I've scanned the inside of the nose and begun to calculate the ratios of the inlet, radiator core and outlet. The image below shows v1.0 of the duct. The dimensions need to be confirmed at which point the outlet will be made 14% larger than the inlet. This accounts for the rejected heat expanding the air after passing through the radiator. I'm currently working on CFD analysis. While not necessary, that's an area that has always interested me.Is the extractor made of fiberglass and bonded into the existing hood?

Brian, I bought a variety of headlights (e.g., Ferrari 458, Ferrari California, etc.) off of Ebay, but I couldn't get anything to fit. My current plan is to make a removable carbon fiber bucket that seals to the existing lens with butyl rope. It will house a dual-beam Morimoto M-LED 2.0 with a Panamera-style shroud. I'm struggling with the best way to implement the switchback DRL. I was going to use a flexible LED tube, but I wasn't sure of the best way to attach it so that it looked OEM and I was worried about it failing and the manufacturer ceasing to exist or changing the dimensions. The current plan is to CNC a flat piece of milky white plastic of some sort. Here is a close up picture of the Ultima RS headlight. If anyone has thoughts, let me know.Carbon headlight buckets- is that something you are making or did you buy them?

I'm also trying to decide if I should trim the lens. The car definitely looks better with smaller lights, but it's more work to trim the lens and fill the gaps in the body. The rendering illustrates a full-sized light..

Scott - thanks for the update on the Lights.Mason, the radiator outlet will be made out fiberglass and it will be bonded to the nose. It will be fed via a fixed duct, made from aluminum or fiberglass, that's sealed to the shroud. I'm currently working on the outlet size to create a diverging-converging duct to maximize mass airflow. There will also be a La-Ferrari-Style vane to reduce drag. The airfoil will be 3D printed and covered in carbon fiber. I've scanned the inside of the nose and begun to calculate the ratios of the inlet, radiator core and outlet. The image below shows v1.0 of the duct. The dimensions need to be confirmed at which point the outlet will be made 14% larger than the inlet. This accounts for the rejected heat expanding the air after passing through the radiator. I'm currently working on CFD analysis. While not necessary, that's an area that has always interested me.

View attachment 108832

Brian, I bought a variety of headlights (e.g., Ferrari 458, Ferrari California, etc.) off of Ebay, but I couldn't get anything to fit. My current plan is to make a removable carbon fiber bucket that seals to the existing lens with butyl rope. It will house a dual-beam Morimoto M-LED 2.0 with a Panamera-style shroud. I'm struggling with the best way to implement the switchback DRL. I was going to use a flexible LED tube, but I wasn't sure of the best way to attach it so that it looked OEM and I was worried about it failing and the manufacturer ceasing to exist or changing the dimensions. The current plan is to CNC a flat piece of milky white plastic of some sort. Here is a close up picture of the Ultima RS headlight. If anyone has thoughts, let me know.

View attachment 108833

I'm also trying to decide if I should trim the lens. The car definitely looks better with smaller lights, but it's more work to trim the lens and fill the gaps in the body. The rendering illustrates a full-sized light..

Regarding your hood design, I am dealing with the same clearance questions with the redesign of my hood. I am planning to make my hood similar to the Ferrari P80/C which is a 1-off customer sponsored car that Ferrari recently created. The hood is absolutely amazing. As are the front wheel vents.

Would it be possible for you to share your scan/cad file of under the hood that you speak about above. That will help my son and it make sure that we can fit our design to the stuff in the compartment beneath it. Your We would really appreciate it.

thanks

Brian

Scott

Lifetime Supporter

Brian, clearance inside the nose varies widely. Some builders have relocated the radiator to the tail and have nothing except a trunk in the nose (e.g. Mesa and Rumbles) and others have everything but the kitchen sink;

My scan isn't of use to anyone because the only part forward of the monocoque that hasn't been completely replaced is the splitter. The only reason that I did the scan was to ensure that the duct cleared the top cross bar in the custom cage and the Penske shock reservoirs that are mounted to it -- I'm not aware of anyone with that configuration. I haven't also haven't made a final decision on the battery which could potentially interfere with the bottom of the duct.

Your best bet is to have someone measure the distance between the vertical plates that support the radiator and the distance from the front of the splitter to the tube that stiffens those plates in front of the footbox. The OD of your vent needs to fit inside of those plates and clear anything that's mounted to them. Unless you reengineer the nose box, your outlet will need to be narrower than the Ferrari's. You also need to consider the ratio of the inlet, radiator core and outlet. That Ferrari appears to have an inlet that's much larger than the SL-C's. The Ultima RS has a similar, but narrower outlet.

- Nose frame stiffeners

- Battery

- Hydraulic lift pump

- Hydraulic lift pump reservoir

- Brake and clutch reservoirs

- A/C dryer

- Shock reservoirs

- Fan shroud

- Horn

- Power brake booster

- Etc.

My scan isn't of use to anyone because the only part forward of the monocoque that hasn't been completely replaced is the splitter. The only reason that I did the scan was to ensure that the duct cleared the top cross bar in the custom cage and the Penske shock reservoirs that are mounted to it -- I'm not aware of anyone with that configuration. I haven't also haven't made a final decision on the battery which could potentially interfere with the bottom of the duct.

Your best bet is to have someone measure the distance between the vertical plates that support the radiator and the distance from the front of the splitter to the tube that stiffens those plates in front of the footbox. The OD of your vent needs to fit inside of those plates and clear anything that's mounted to them. Unless you reengineer the nose box, your outlet will need to be narrower than the Ferrari's. You also need to consider the ratio of the inlet, radiator core and outlet. That Ferrari appears to have an inlet that's much larger than the SL-C's. The Ultima RS has a similar, but narrower outlet.

Similar threads

- Replies

- 10

- Views

- 8K

- Replies

- 3

- Views

- 4K