Hi Keith,

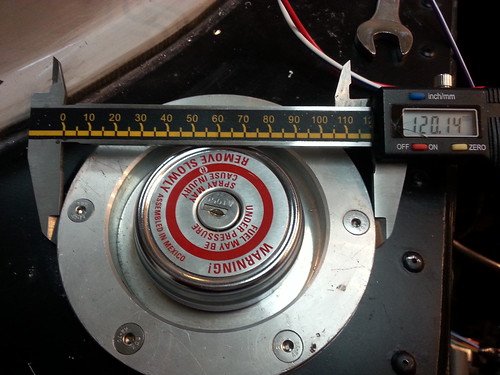

Regarding the filler caps, according to the regs they don’t have to be lockable, but they do have to be tethered. I used brake cable from a push bike and made the crimps out of a small length of brake pipe

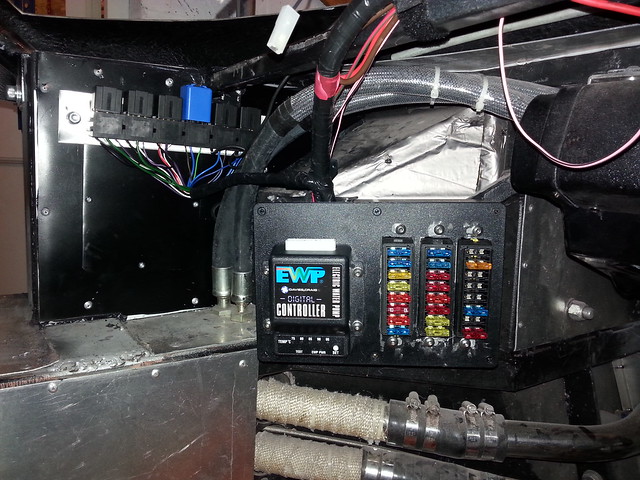

The filler flanges and tank will need to be modified to add a separate vent line, otherwise the tanks won’t fill properly see attached. Note the blue silicon hose was for mock-only as it’s not fuel resistant. The smaller line is the breather line to atmosphere which gores through the roller-over valve (stops fuel spilling if the car is inverted)

Regards,

Andy

Regarding the filler caps, according to the regs they don’t have to be lockable, but they do have to be tethered. I used brake cable from a push bike and made the crimps out of a small length of brake pipe

The filler flanges and tank will need to be modified to add a separate vent line, otherwise the tanks won’t fill properly see attached. Note the blue silicon hose was for mock-only as it’s not fuel resistant. The smaller line is the breather line to atmosphere which gores through the roller-over valve (stops fuel spilling if the car is inverted)

Regards,

Andy