Basically yes but it's a bit more complicated than that.

Each sensor is polled every clock cycle and the running average over a period of time is taken to be the sensor value.

Each sensor then has a table which translates the sensor value to the actual fuel amount. The total fuel amount is then added and another table maps it to the gauge.

The gauge is then only updated every few seconds. The net effect is that no matter how I throw the car around (once I get to that stage!) the gauge won't wildly fluctuate.

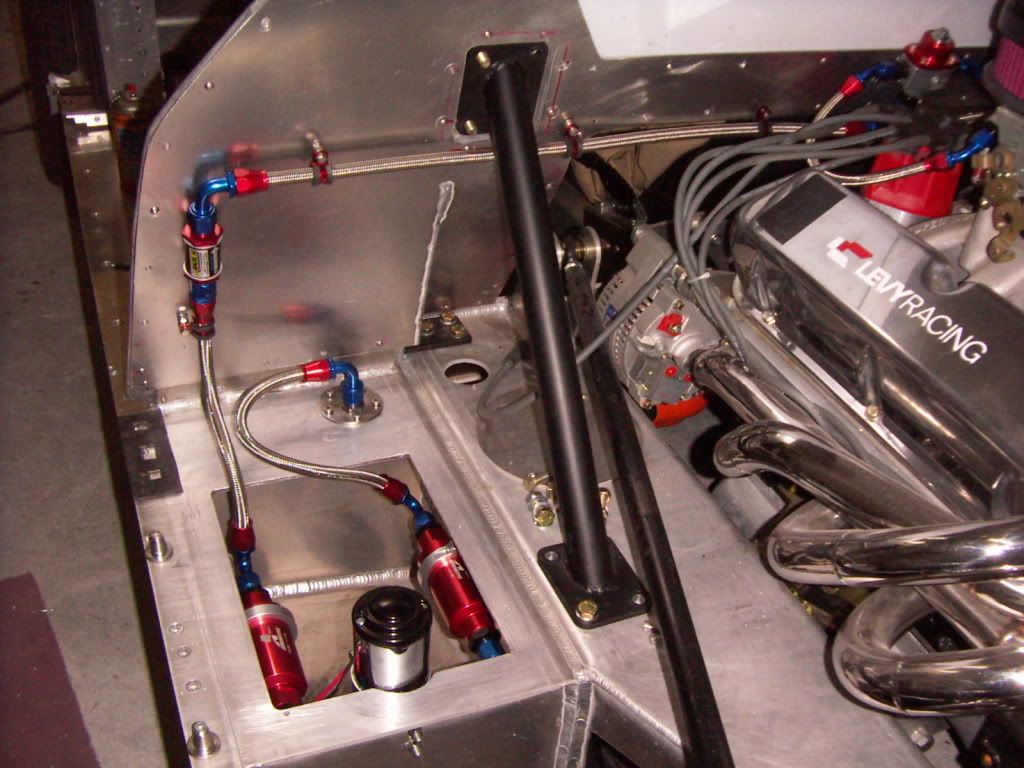

In addition it controls the individual lift pumps (to the swirl pot), alternating between tanks by 'picking' the one with the highest fuel level and shutting down the pump if the tank runs 'dry'.

Plus of course a low warning light.

Each sensor is polled every clock cycle and the running average over a period of time is taken to be the sensor value.

Each sensor then has a table which translates the sensor value to the actual fuel amount. The total fuel amount is then added and another table maps it to the gauge.

The gauge is then only updated every few seconds. The net effect is that no matter how I throw the car around (once I get to that stage!) the gauge won't wildly fluctuate.

In addition it controls the individual lift pumps (to the swirl pot), alternating between tanks by 'picking' the one with the highest fuel level and shutting down the pump if the tank runs 'dry'.

Plus of course a low warning light.