Scott

Lifetime Supporter

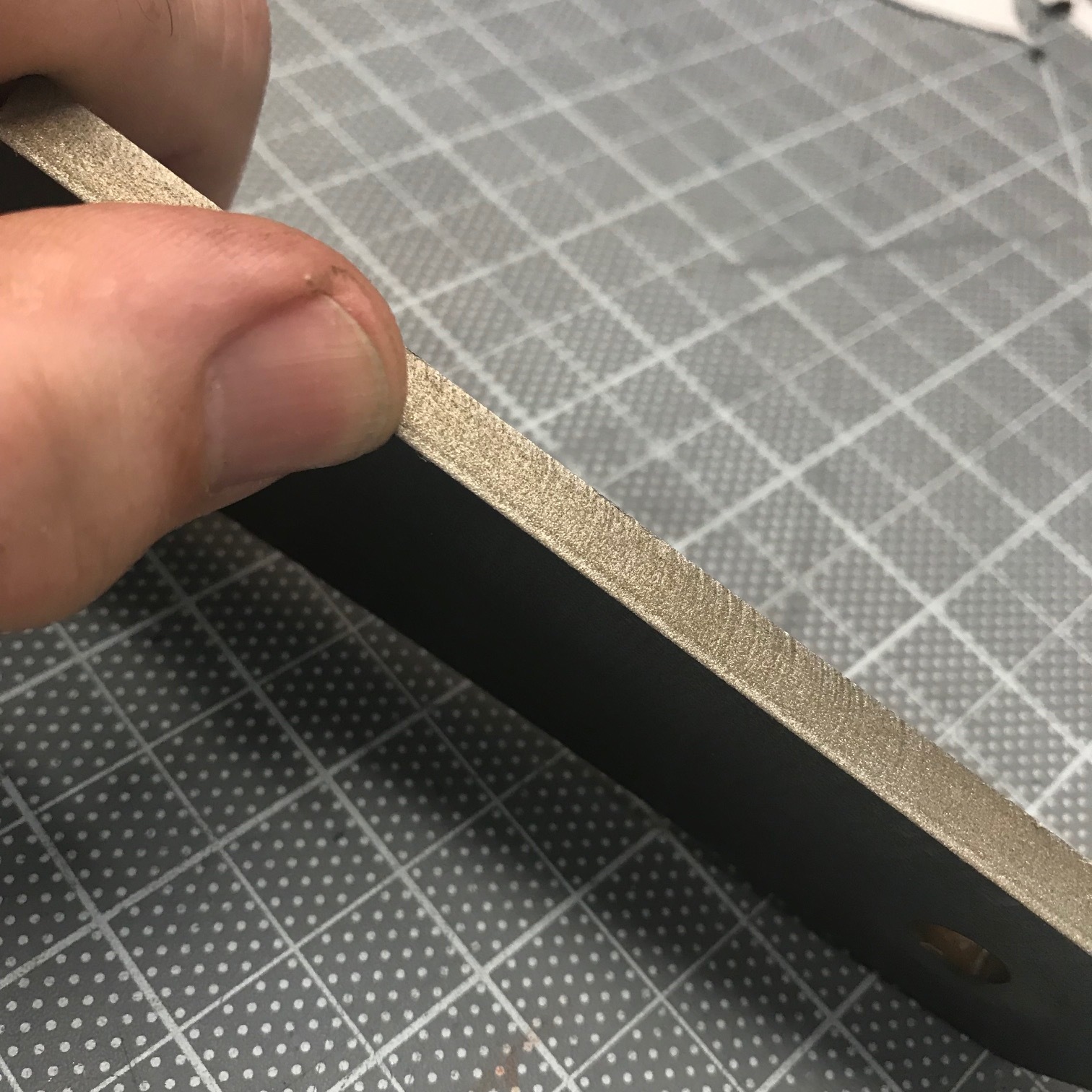

I cut the the front tow hook out of 1/4” cold rolled steel. At two hours and 42 minutes it was by far the longest cut that I have done. I was a bit nervous about having an issue in the middle of the cut which would waste a lot of abrasive not to mention the material because during a previous cut the Wazer stopped cutting all of the way through a piece of 1/8” stainless steel.

When this happens the water jet and abrasive bonces off the material in the direction opposite to the cutting head’s motion. Unfortunately the seam between the lid and the sides is not well sealed and some water and abrasive will escape. If you don’t catch this right away you’ll have a bit of a mess to clean up. While the mess is manageable, water will drip down the side and into the abrasive hopper which wrecks it (i.e., makes it lumpy which will cause a clog). I scooped all of the wet abrasive out using a specialized tool… I know that it looks like a serving utensil, but I would never use a kitchen implement in the garage;-)

Specialized abrasive removal tool

The cutting stream’s bounce back when piercing doesn’t case any issues. I assume this is because it bounces back vertically into the cutting head.

After running a test I determined that the abrasive flow rate was too low so I emptied all of the abrasive and used compressed air to ensure the abrasive feed tube was clear. After that everything worked fine. As can be seen in the picture below, the cut quality was outstanding. The cut consumed a whopping 53.4 pounds of abrasive. While that seems completely uneconomical, that’s $76.89 if you purchase by the bucket and only $24.03 if you purchase by the palette. Even the higher bucket price is about half of the minimum cut fee around here.

Excellent cut quality

Temporary paint and soft strap

I cleaned up the edges with a mini sander and sprayed it with some rattle-can red (I'll powder coat it later). The short soft strap keeps the metal hook from marring the hook or diffuser.

A couple of takeaways:

- Per the manual, stay in the same room as the Wazer when cutting. When the water jet is bouncing off of the material is makes a different sound which will alert you to look at it. Unfortunately, the piercing operation sounds the same so you need to look at the LCD panel to determine it’s piercing or cutting. If it’s cutting, you have an issue.

- Wazer should have designed a channel into the top of the abrasive hopper so that water dripping down the side doesn’t contaminate the abrasive.

- Wazer needs to add a feature that allows a cut to be restarted at a given place. If this cut had failed like the prior one did, it would have wasted over $100 of material and abrasive.