It has been awhile since I have check in on your build Tom -

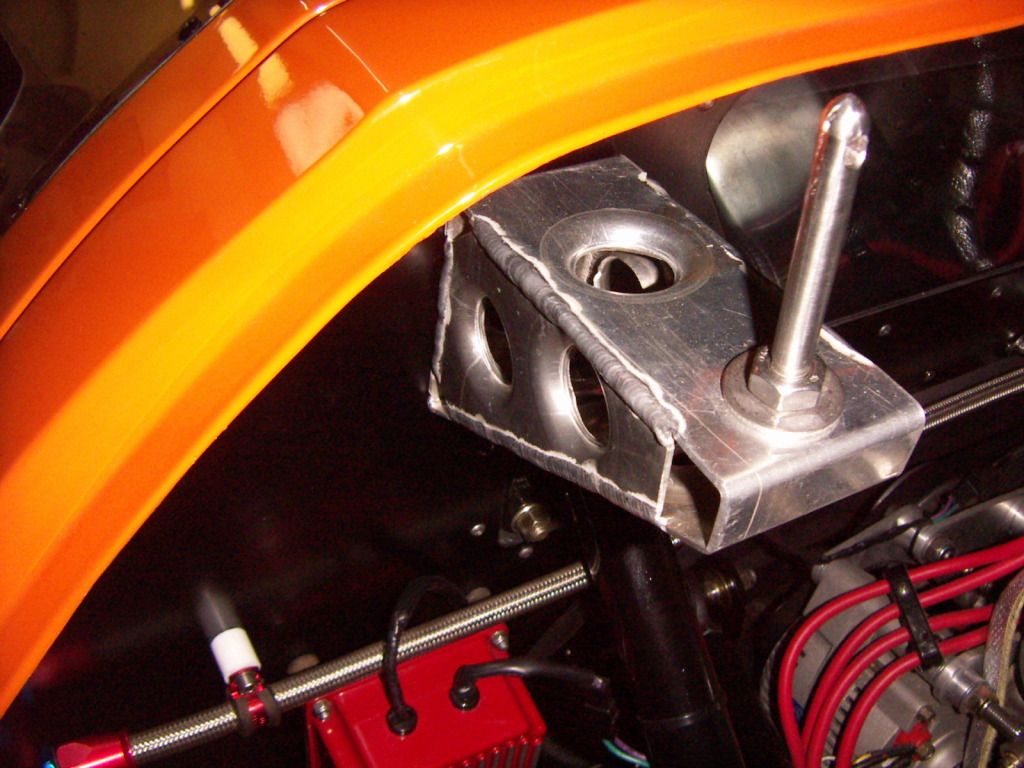

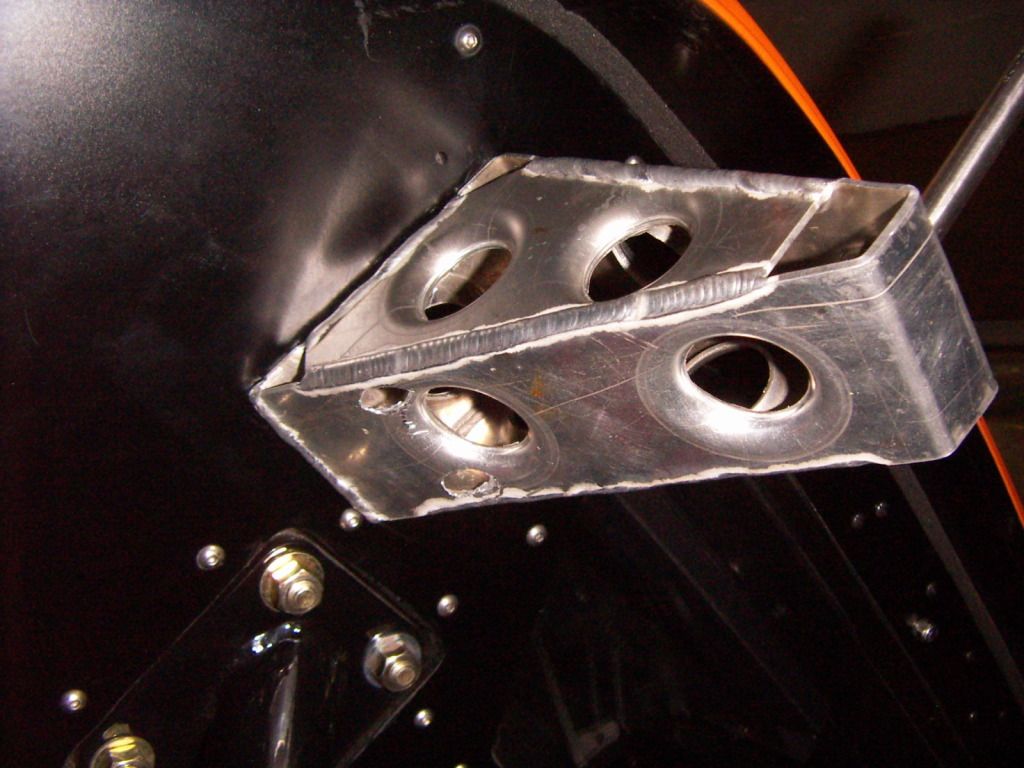

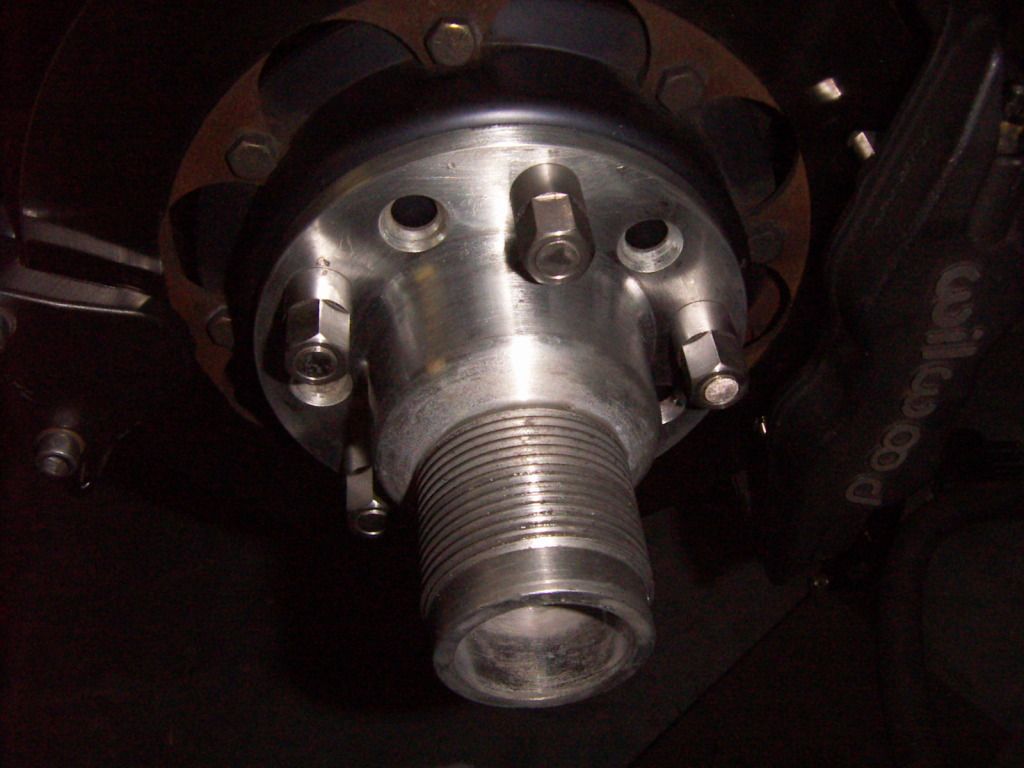

As usual you continue to select "just" the right detail for everything you include or modify on your car. From your hand made flares through to your final wheel selection, very nice taste. I like the way the wheel hats don't cone down to meet the wheel centers until they actually meet the wheel centers. Also enjoy the hidden three piece wheel bolts (even though I could not hide such on my car).

VERY nice work.

GT40s do indeed have beautiful proportions, as do the wheels and tires you selected for it. I think I will include your car on my desktop for awhile.

Cheers.

P.S. I think I read or heard somewhere that you will be building an SLC? If so, I will enjoy seeing your "take" on that car when you get to it.

As usual you continue to select "just" the right detail for everything you include or modify on your car. From your hand made flares through to your final wheel selection, very nice taste. I like the way the wheel hats don't cone down to meet the wheel centers until they actually meet the wheel centers. Also enjoy the hidden three piece wheel bolts (even though I could not hide such on my car).

VERY nice work.

GT40s do indeed have beautiful proportions, as do the wheels and tires you selected for it. I think I will include your car on my desktop for awhile.

Cheers.

P.S. I think I read or heard somewhere that you will be building an SLC? If so, I will enjoy seeing your "take" on that car when you get to it.