You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tornado Build - www.gt40builder.com

- Thread starter trevorsummers

- Start date

I couldn't resist hoping in the car and pretending to drive the car ?

Your so sad Trev.

p.s. I do it all the time and make brum brum noises

Looking very nice mate

Keith, you won't have to pretend for much longer the rate your build is going

Just wait till there's a motor to make those wonderful sounds.

Bill

Bill

steering coupler housing

Hi all

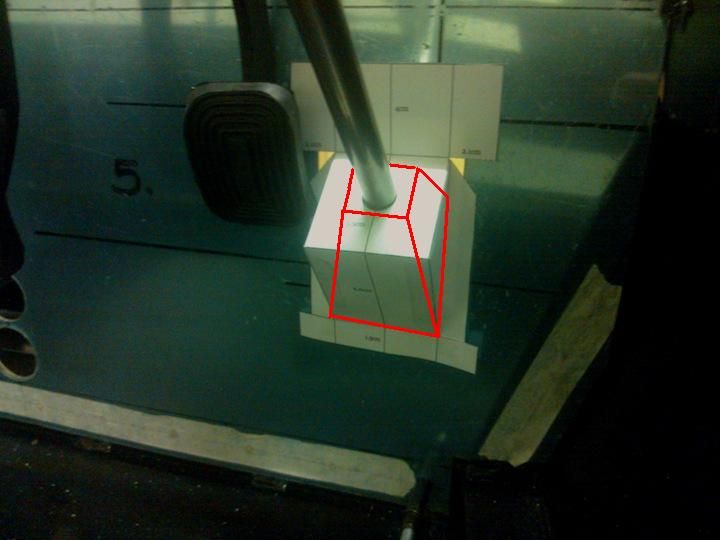

Spent today mocking up a housing for my steering coupler while watching the F1. I've copied what others on here have done with their housings but the problem I am having is that the brake pedal fouls the corner of the housing. What I don't know is how far forward the pedals will sit when everything is assembled and if this is going to be an issue.

I was trying to copy what Andy Green has done with his. What I can't see from his pictures is if he has the same issue.

Can anyone give me some advice

Hi all

Spent today mocking up a housing for my steering coupler while watching the F1. I've copied what others on here have done with their housings but the problem I am having is that the brake pedal fouls the corner of the housing. What I don't know is how far forward the pedals will sit when everything is assembled and if this is going to be an issue.

I was trying to copy what Andy Green has done with his. What I can't see from his pictures is if he has the same issue.

Can anyone give me some advice

It looks like Andy both has smaller pedals *and* a smaller housing.

Stick up a pic without the housing so we can see what we're working with.

Is that bracket on the right for the accelerator? Might want to check that doesn't foul either. Hard to tell from the angle but looks as if it might.

Stick up a pic without the housing so we can see what we're working with.

Is that bracket on the right for the accelerator? Might want to check that doesn't foul either. Hard to tell from the angle but looks as if it might.

Trev,

From what I can see, the down leg of the shaft seems to be more acute on Andys. That is it points down more than yours, which would make the first length of shaft a little longer.

-----\ ------l

If this is just an optical illusion, then I would suggest moving the pedal pad only so that it misses the shaft. You need to consider one more thing. When the pedal misses the shaft, what will your foot do!!?? Would it hit the shaft also? This might make the distance between the brake and clutch pedal too close??? Another alternative is to hack the pedal assembly so that the clutch and the brake units as a whole are a little more to the left, if there aren't any other constraints.

Bill

From what I can see, the down leg of the shaft seems to be more acute on Andys. That is it points down more than yours, which would make the first length of shaft a little longer.

-----\ ------l

If this is just an optical illusion, then I would suggest moving the pedal pad only so that it misses the shaft. You need to consider one more thing. When the pedal misses the shaft, what will your foot do!!?? Would it hit the shaft also? This might make the distance between the brake and clutch pedal too close??? Another alternative is to hack the pedal assembly so that the clutch and the brake units as a whole are a little more to the left, if there aren't any other constraints.

Bill

Brett James-McCall

Moderator

Trevor,

I cut down one of these and am then clamping it to the bulkhead.

Universal Convoluted Rubber Gear Gaiter - GRGTR

Just another thought for you

Brett

I cut down one of these and am then clamping it to the bulkhead.

Universal Convoluted Rubber Gear Gaiter - GRGTR

Just another thought for you

Brett

Hi Trev,

my cover is only slightly wider than the coupling, so does not foul either of the pedals. Brett's solution is simplest, but I prefer to make something where feasible. Attached photos gives a better view of the finished part

Regards

Andy

Thanks for the picture Andy. Could you tell me how much of a gap there is between the housing and your brake pedal? Without the pedal cover on my pedal it just clears it but should I be allowing at least 10ml, 20ml etc as a minimum clearance level so my foot doesn't bang the housing?

Off hand, I think I set the clearance to the pedal arm to about 5-10mm. Remember your brake pedal hardly moves and if it does there's more to worry about than your foot hitting the housing !!!

Andy

Andy

OK time for another update on the housing. I produced another housing template that is just about as wide as the bolt that passes through the UV joint. It's now a little too small and needs to be a little big but the brake pedal now does clears the housing.

You can see from the next picture from the back that this housing is a little too small and needs to be around 4mm wider to clear the bolt and allow the extra room that the aluminium will take up. However that would mean that the brake pedal would foul the housing again

So by making the housing wider to fit the joint it will foul the brake pedal. Also if you look at the next picture with the couple removed you can see even if I get a housing to fit the accelerator bracket placement means that the pedal looks like to foul the housing more so than the brake pedal.

Hmm, not too good. I can't see a elegant and easy way of getting a housing to work. The other option is to put a rubber cover over like bill's build.

What do we think?

You can see from the next picture from the back that this housing is a little too small and needs to be around 4mm wider to clear the bolt and allow the extra room that the aluminium will take up. However that would mean that the brake pedal would foul the housing again

So by making the housing wider to fit the joint it will foul the brake pedal. Also if you look at the next picture with the couple removed you can see even if I get a housing to fit the accelerator bracket placement means that the pedal looks like to foul the housing more so than the brake pedal.

Hmm, not too good. I can't see a elegant and easy way of getting a housing to work. The other option is to put a rubber cover over like bill's build.

What do we think?

A hex head bolt is slimmer than a socket cap which might gain you those 4mm.

Use a flange head bolt and you could also lose the washer.

I did think about changing the bolts but the ones I am using have been provided by Gelscoe. They weren't happy with the plated hex bolts provided to me as they were threaded all the way through. They told me that the bolts should ideally have a solid shank which these bolts have. Also wouldn't the nut on the opposite side still mean the overall width would be the same?

Ah, I presumed it needed no nut on the other end.

Strictly speaking that bolt shouldn't be under any appreciable load (although it really doesn't want to come loose!) but I'm assuming that there is a 'groove' on the shaft that the bolt fits through and prevents the shaft coming out unless the bolt is removed? In which case they are correct (heh, that sounds wrong, I'm sure they know more than me) but it doesn't have to be *that* bolt. You could get a flanged hex head bolt with the same shank size.

Strictly speaking that bolt shouldn't be under any appreciable load (although it really doesn't want to come loose!) but I'm assuming that there is a 'groove' on the shaft that the bolt fits through and prevents the shaft coming out unless the bolt is removed? In which case they are correct (heh, that sounds wrong, I'm sure they know more than me) but it doesn't have to be *that* bolt. You could get a flanged hex head bolt with the same shank size.

Thats a very substantial UV joint, do you really need one that big?

You could remake that panel with a circular hole and then use a small CV boot as Phil said. And you would probably get away with a much smaller aperture as well (your hole looks too tall).

You could remake that panel with a circular hole and then use a small CV boot as Phil said. And you would probably get away with a much smaller aperture as well (your hole looks too tall).

UH....maybe bend the brake pedal. Actually we do it all the time for driver comfort as well as clearance. May not work for you but it is an option.

Brett James-McCall

Moderator

What do we think?

I think for £12 you should maybe have at look at what I suggested, it pushes the cover forward and is not flush with the bulkhead. You have the best of both worlds. 1. It will compress if your foot touches it, and 2/ the gaiter allows for the bolt.

Mine isn't even attached, I'd be prepared to send it to you to try out!

Similar threads

- Replies

- 3

- Views

- 2K

- Replies

- 2

- Views

- 550

- Replies

- 26

- Views

- 2K

- Replies

- 3

- Views

- 730