Reassembly Begins

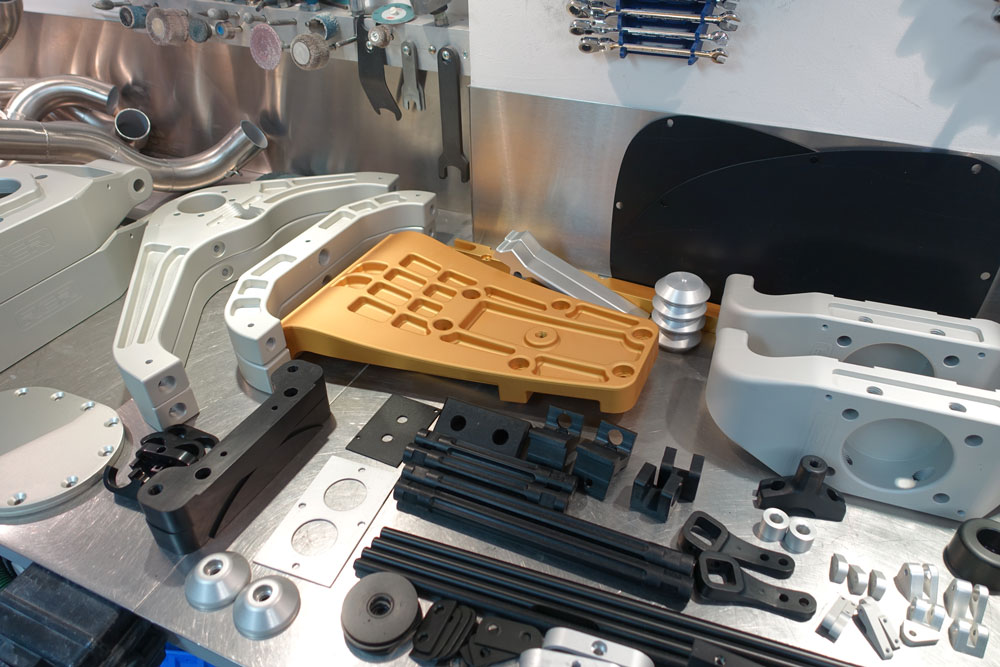

The reassembly of the Chassis in preparation for the painted body has begun. All parts that are finally torqued are marked so I know what is still loose. Some parts still need to come off to do the final job which is all electrical wiring.

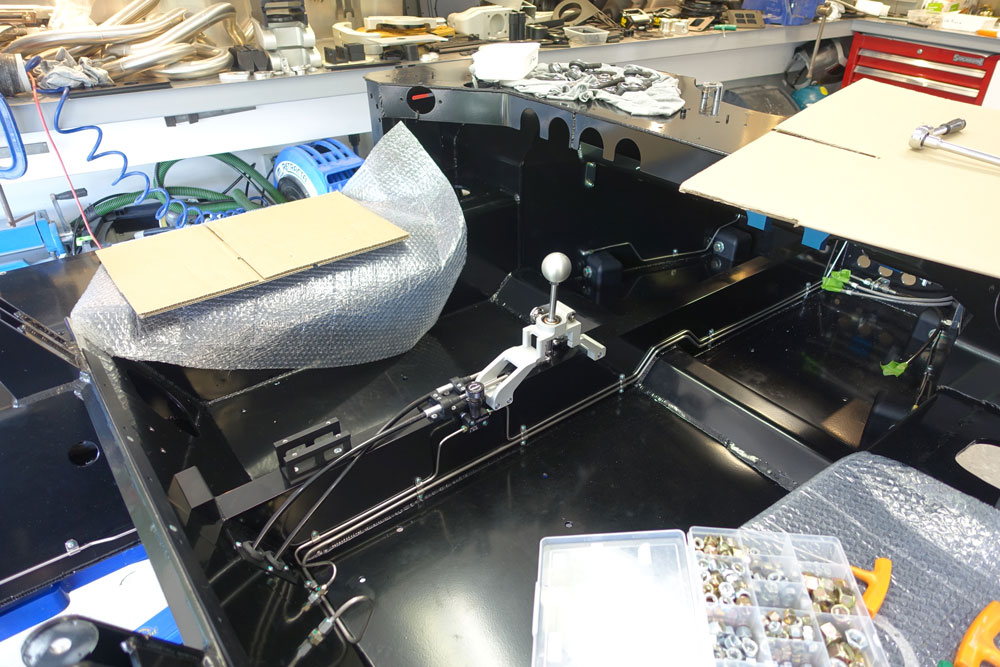

The final fix for the brakes, clutch and lift kit took some time. Lining up all those clip points was a bit of work.

Fitting the gear shift was great. Having it in its final anodised finish looks great.

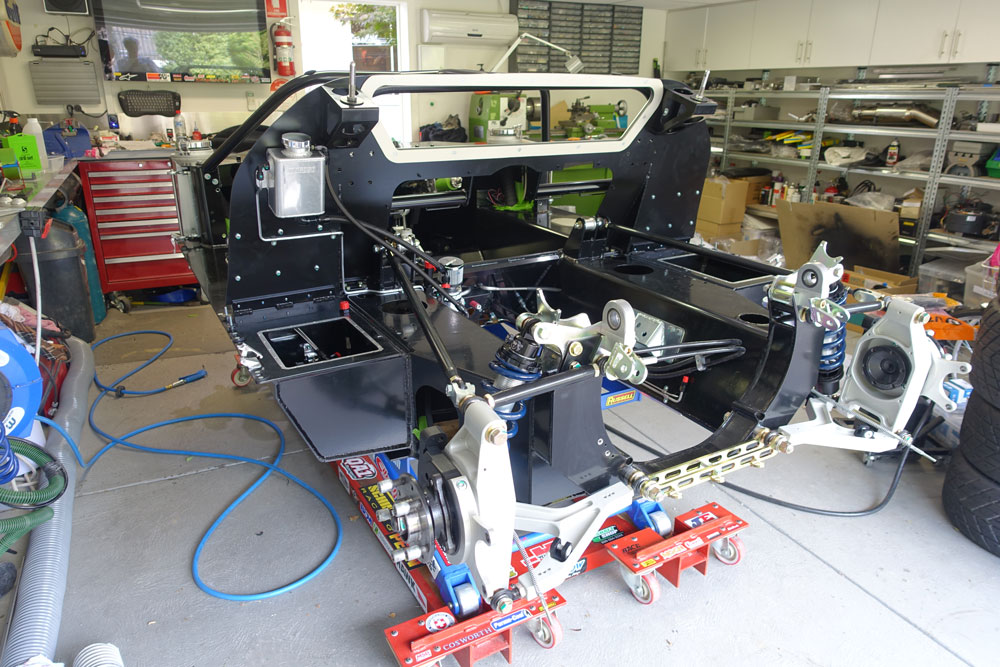

Assembly of the suspension went well. With all the modifications it was tricky to do. Having all the parts zinc plated for the first time looks great.

Having each part anodised black or zinc plated will allow this look to remain. No paint was used with the exception of the few black steel parts which really is limited to black suspension rods and roll cage which were powder coated.

Finally with parts going on the car I'm getting some room back in my tiny workshop!

I have had the entire rear firewall ceramic coated in black. I would like to see if this reduces heat transfer enough to not require heat shielding. We will see!

May make the rear window surround black anodise, the natural anodise stands out a bit.

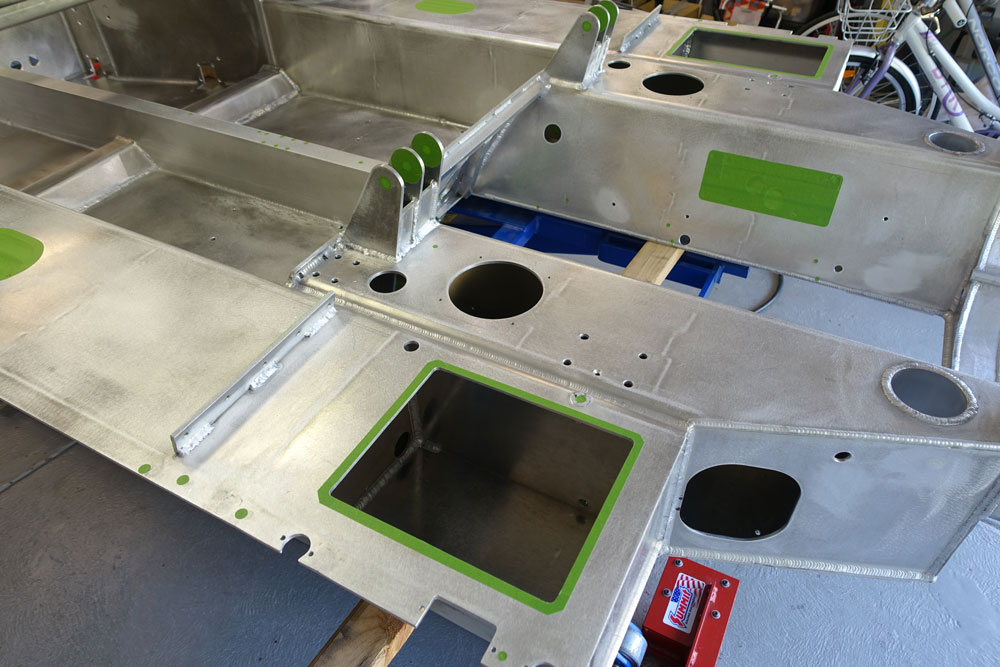

The decision to powdercoat that lovely alloy chassis was a tough one, but I am glad I did. I think it looks much better.

Next to fit the engine temporarily. I want the chassis in exact "position" as the body should be ready for a pre-fit to line up and mask out the orange stripe and roundels. Cannot wait for that!